Patents

Literature

38results about How to "Simple polishing process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

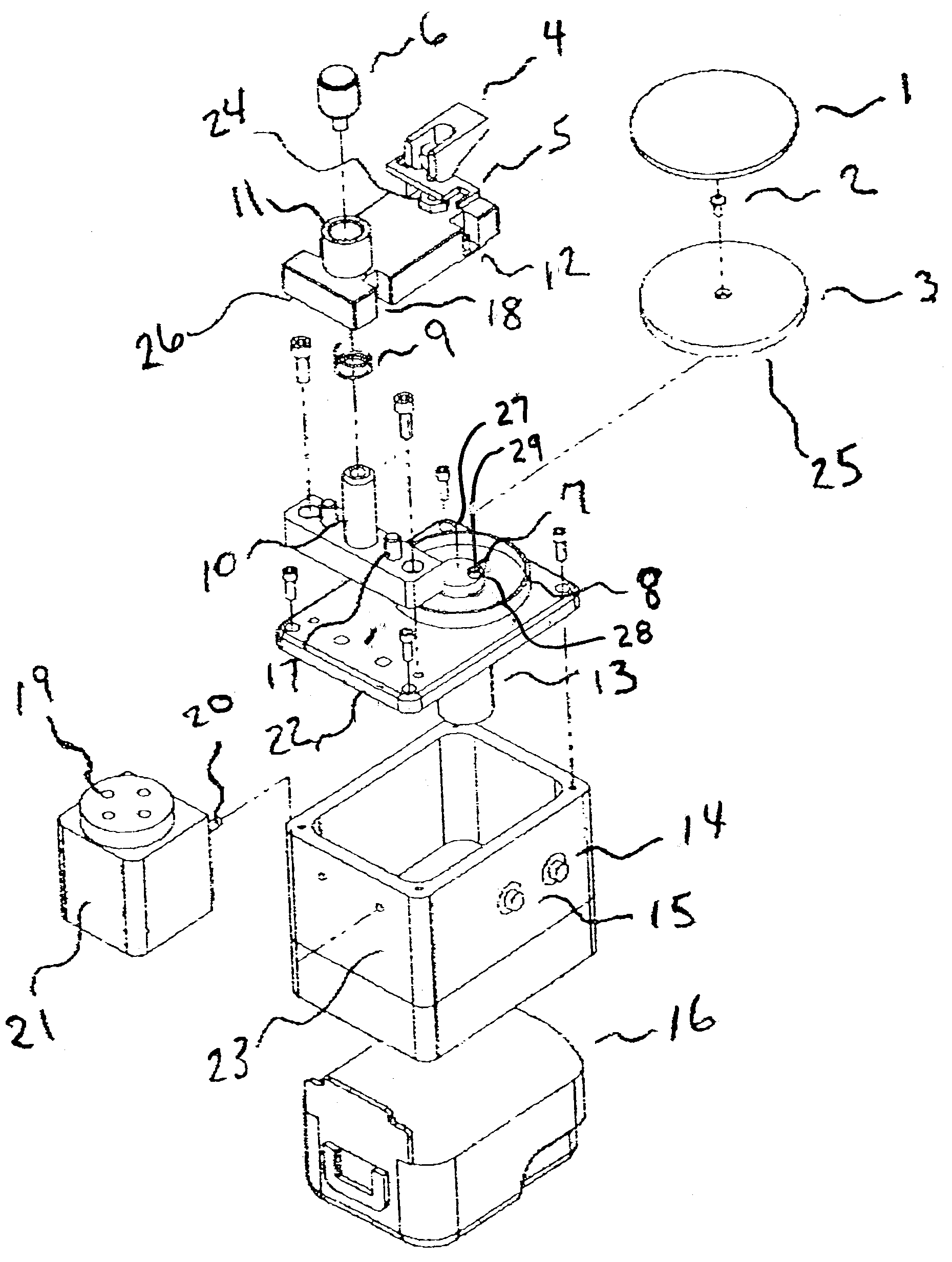

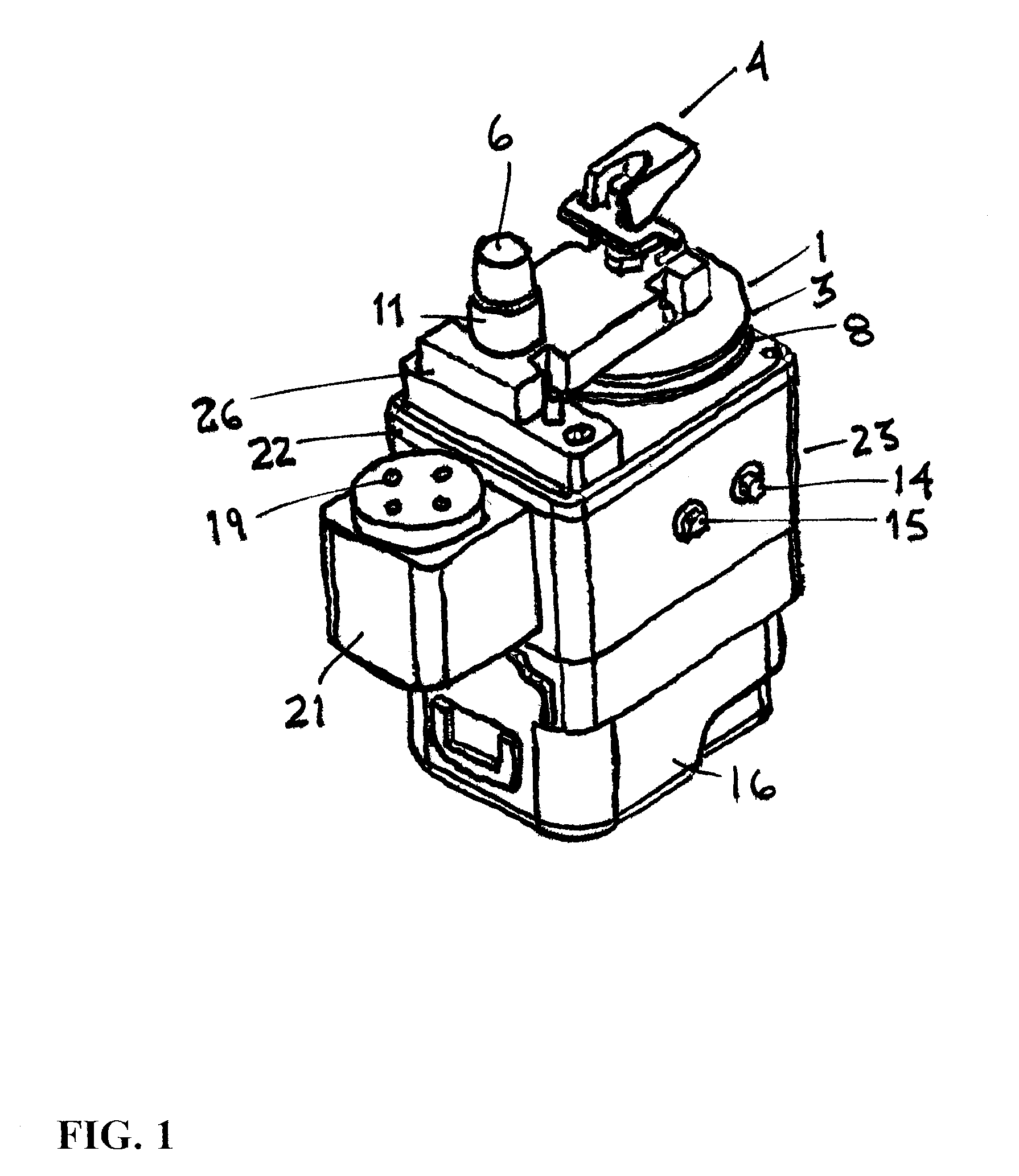

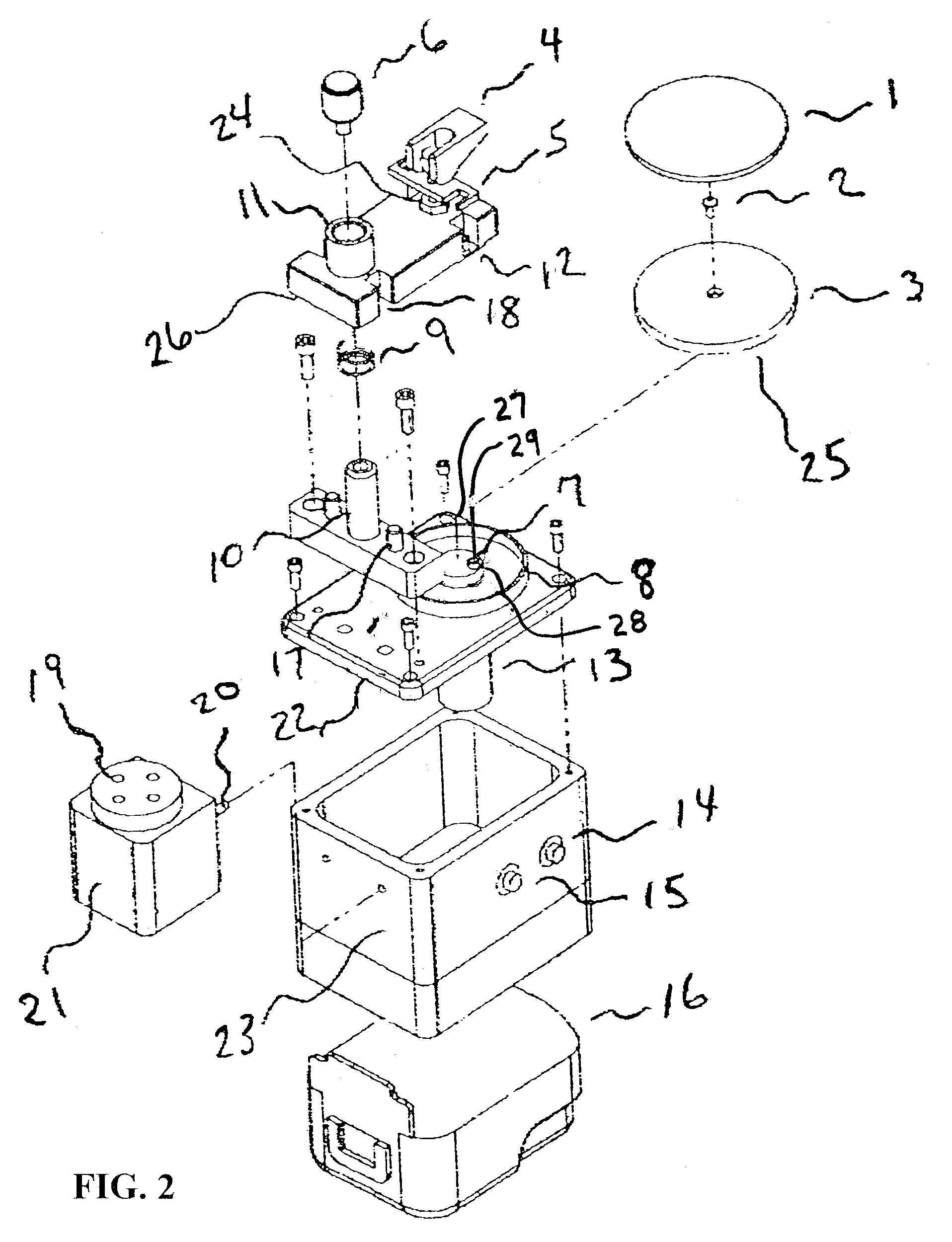

Portable optical fiber polisher

InactiveUS7217174B1Few stepsLess timeEdge grinding machinesPlane surface grinding machinesFiberContact pressure

A polisher has an offset axis and a friction cam useful in a method of polishing that comprises a more random, elongated polishing pattern than known orbital polishers and is capable of portable use using a 9 volt battery. The method is capable of using lower contact pressures between fiber ends and a polishing surface and higher rates of rotation of the drive mechanism, reducing the polishing time for preparing fiber ends for applications. The polishing pattern changes when pressure is applied between a fiber end and the polishing surface. The fiber end provides one intermittent axis of rotation and the friction cam provides another intermittent axis of rotation.

Owner:MF LIGHTWAVE

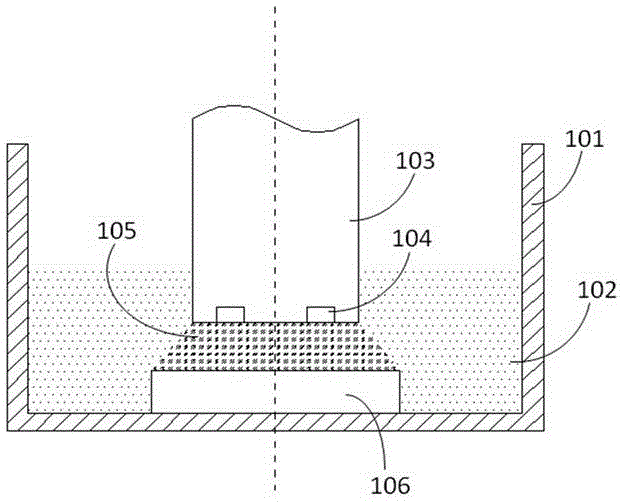

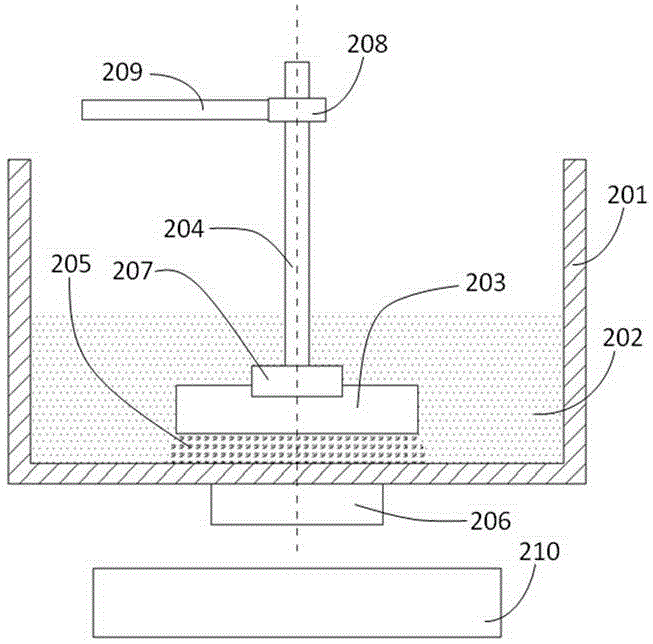

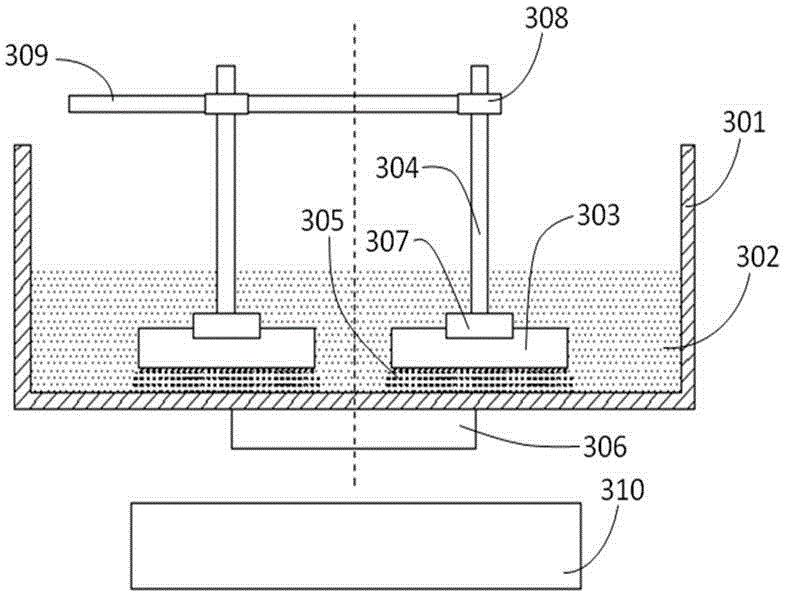

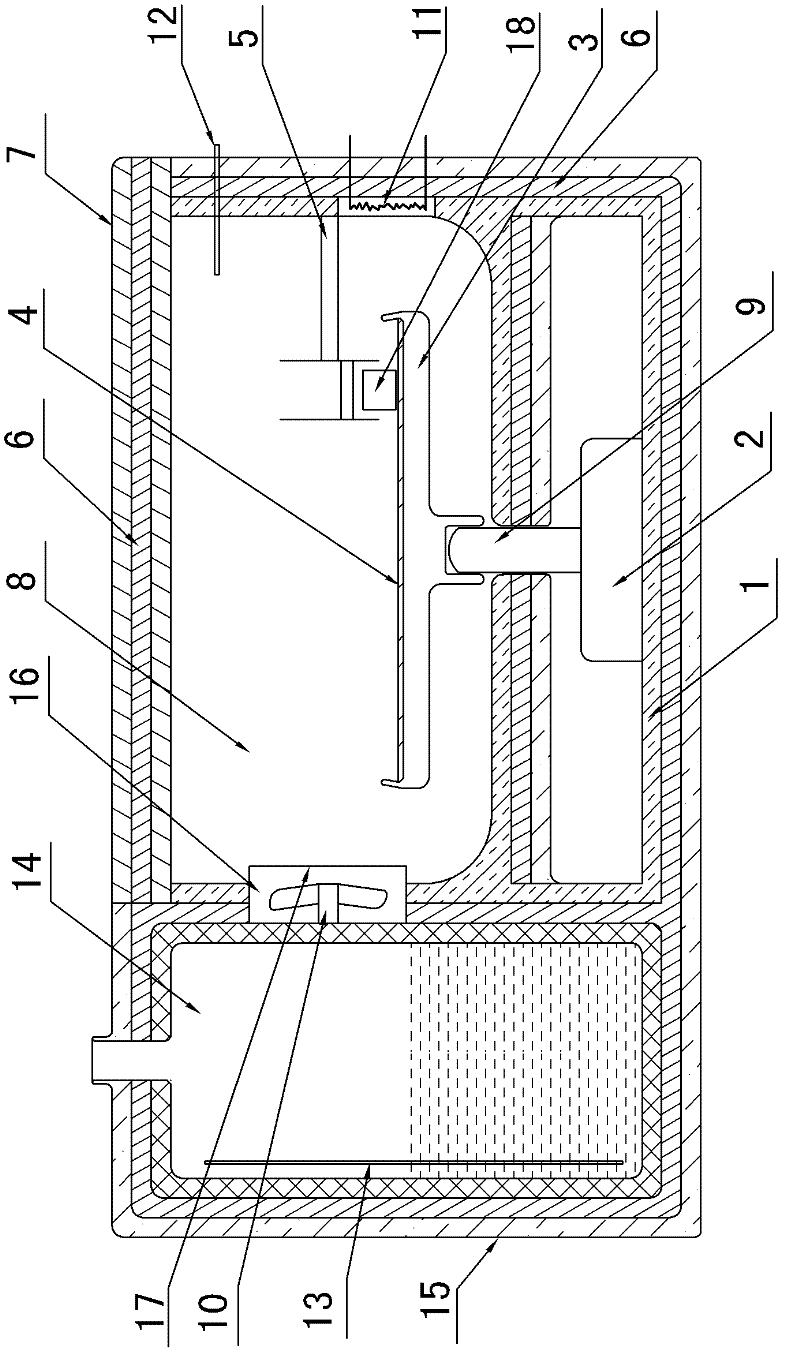

Magneto-rheological amorphous alloy polishing device, polishing agent and polishing method

InactiveCN105904332AEfficient polishingHigh gloss mirror effectEdge grinding machinesPolishing machinesReciprocating motionAlloy

The invention discloses a magneto-rheological amorphous alloy polishing device which comprises a polishing groove, a fixed clamping device, a motor and a magnetic field generation device, wherein a magneto-rheological polishing agent is stored in the polishing groove; a to-be-polished work piece is fixed in the polishing agent by the fixed clamping device, so that a gap is formed between a polishing face of the work piece and the bottom of the polishing groove; the magnetic field generation device is disposed outside the polishing groove, and an external magnetic field generated by the device makes magnetic particles in the magneto-rheological polishing agent generate rheological effects, so that a magneto-rheological aggregate is formed between the work piece polishing face and the bottom of the polishing groove; and the motor is connected to the polishing groove and can drive the polishing groove to rotate or move back and forth. The polishing device disclosed by the invention has the advantages that a magneto-rheological polishing technology is applied in amorphous alloy polishing; the polishing device applicable to use is provided; an amorphous alloy product can be polished effectively, so that a surface with specular gloss can be obtained; the polishing technology is simple and can be implemented easily; and the polishing device is applicable to large-scale production.

Owner:宋佳

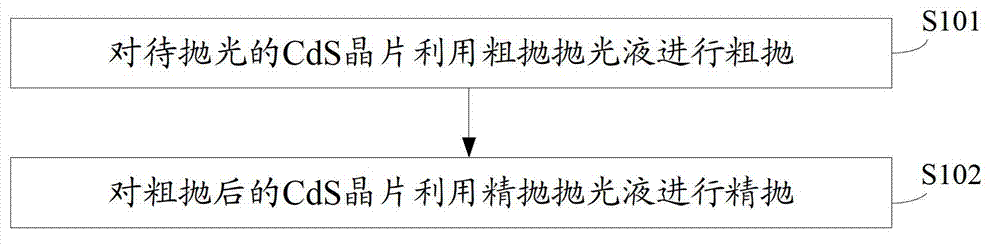

Polishing solution and method for polishing cadmium sulfide (CdS) wafer by applying same

InactiveCN102952467AAvoid damageEasy to cleanLapping machinesPolishing compositions with abrasivesSurface-active agentsCadmium sulfide

The invention discloses a polishing solution used for chemico-mechanical polishing, which comprises polishing solution for rough polishing and polishing solution for fine polishing, wherein the polishing solution for rough polishing comprises 5-10wt% of nano grinding material, 1.5-3wt% of oxidant, 0.01wt% of surface active agent, pH regulator and the balance of deionized water, and has the particle size of 60-100nm and the pH value of 9.5; the polishing solution for fine polishing comprises 1-5wt% of nano grinding material, 0.5-1.5wt% of oxidant, 0.01wt% of surface active agent, pH regulator and the balance of deionized water, and has the particle size of 15-30nm and the pH value of 9.5; and the invention also relates to a method for carrying out chemico-mechanical polishing on a cadmium sulfide (CdS) wafer by applying the polishing solution, which comprises the steps of: carrying out rough polishing on the CdS wafer to be polished by the polishing solution for rough polishing, and then carrying out fine polishing on the CdS wafer by the polishing solution for fine polishing after rough polishing, wherein during the rough polishing and the fine polishing, the polishing pressure is 60-120g / cm<2>, the rotating speed is 60-100r / min, and the flow rate of the corresponding polishing solution is 50-200ml / min. The invention is simple in polishing technology, easy in operation and less in damage caused by the used polishing solution.

Owner:CHINA ELECTRONICS TECH GRP NO 46 RES INST

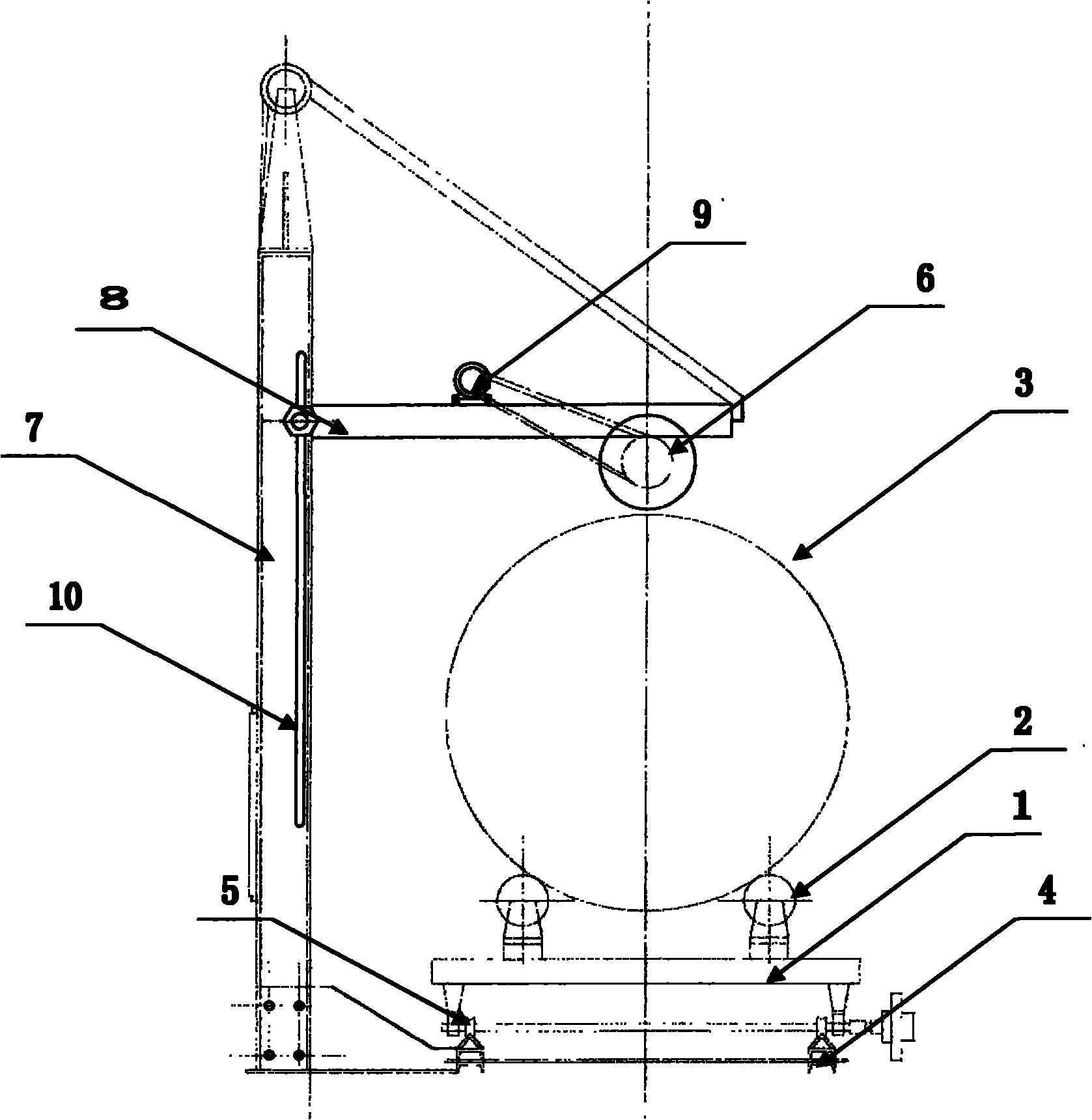

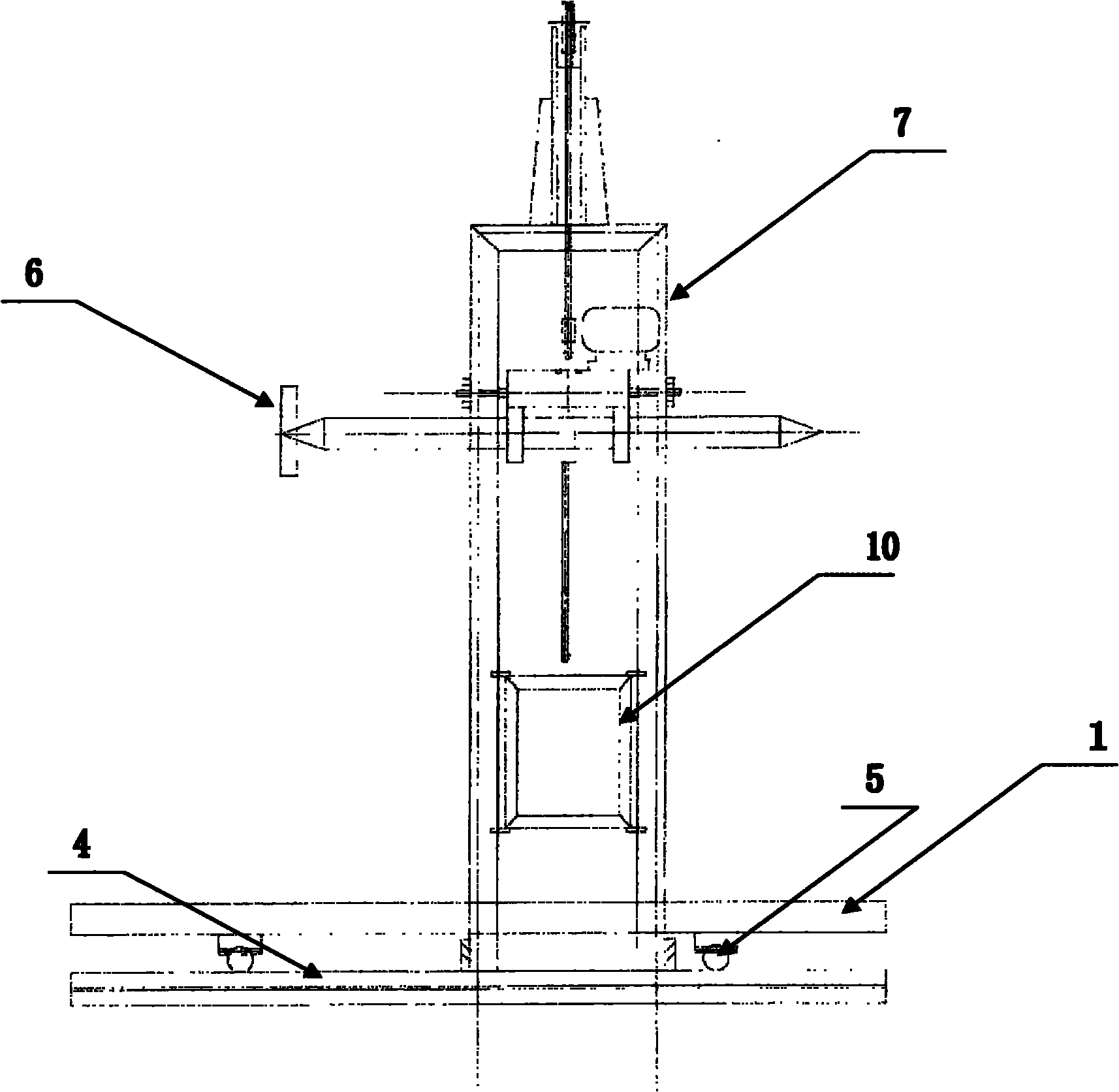

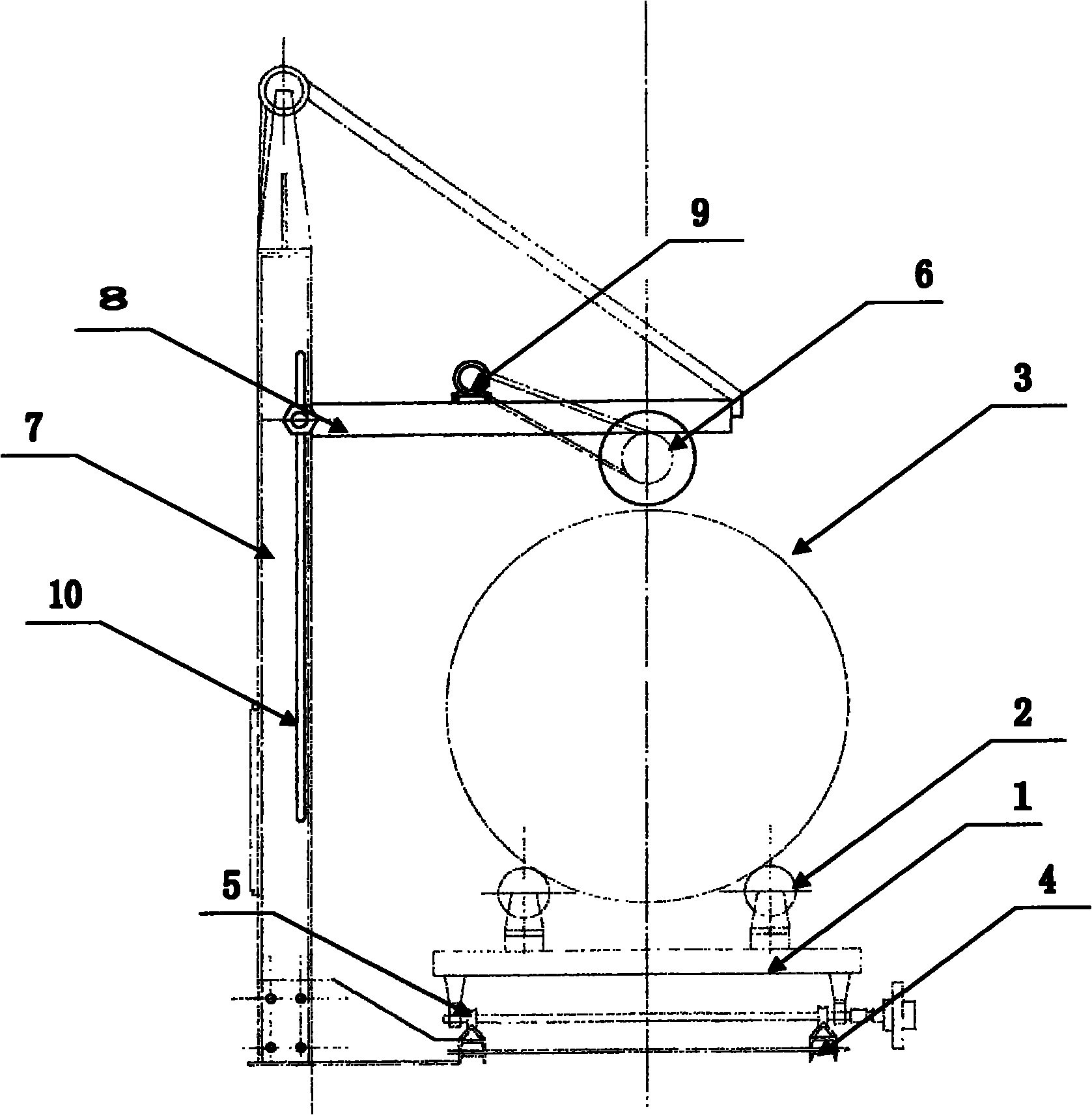

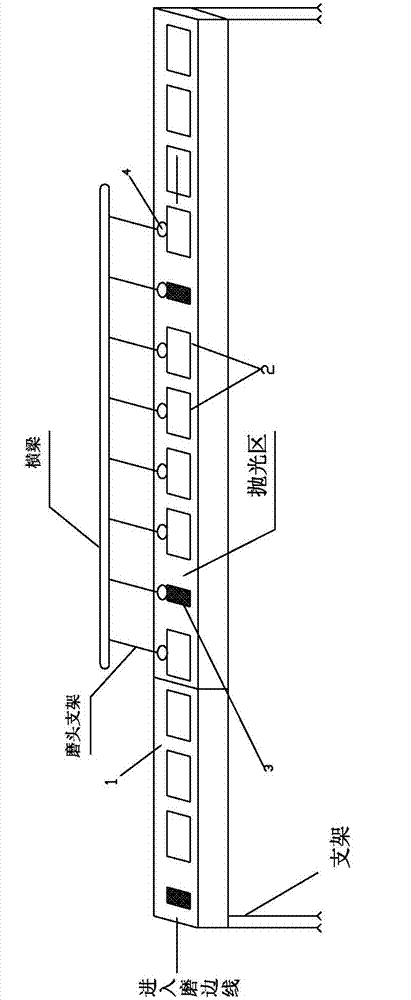

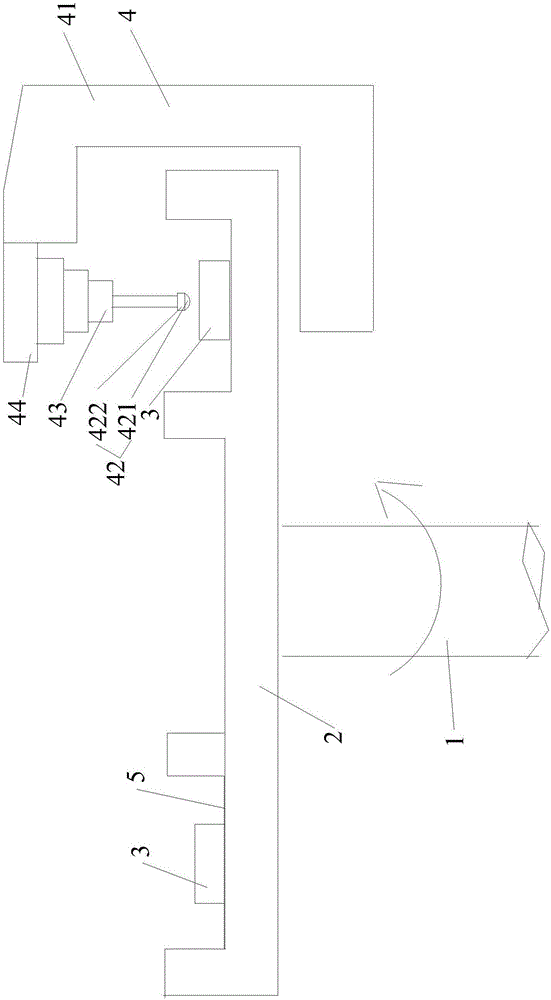

Automatic polishing machine

InactiveCN102049721ASimple polishing processReduce work intensityPolishing machinesElectric machineryEngineering

The invention proposes an automatic polishing machine which can be used for the manufacture field of chemical machinery, ships, thermal machinery, etc. and is mainly used for automatically polishing large components, such as barrel bodies or pot bodies, so as to lighten the labor intensity of operators. The automatic polishing machine is implemented by the way that a movable workbench is arranged; a row of a plurality of idler wheels are respectively arranged on both sides of the movable workbench; a barrel body or pot body to be polished is arranged on the idler wheels; a guide rail is arranged below the workbench, and the workbench can forward and backward move on the guide rail; a cast disc performs polishing operation by attaching to a workpiece under the support of a cast disc bracket and a cast disc jib; and simultaneously, driven by a motor, the workbench drives the workpiece to axially and radially move so as to polish the whole surface of the workpiece.

Owner:陆惠琪

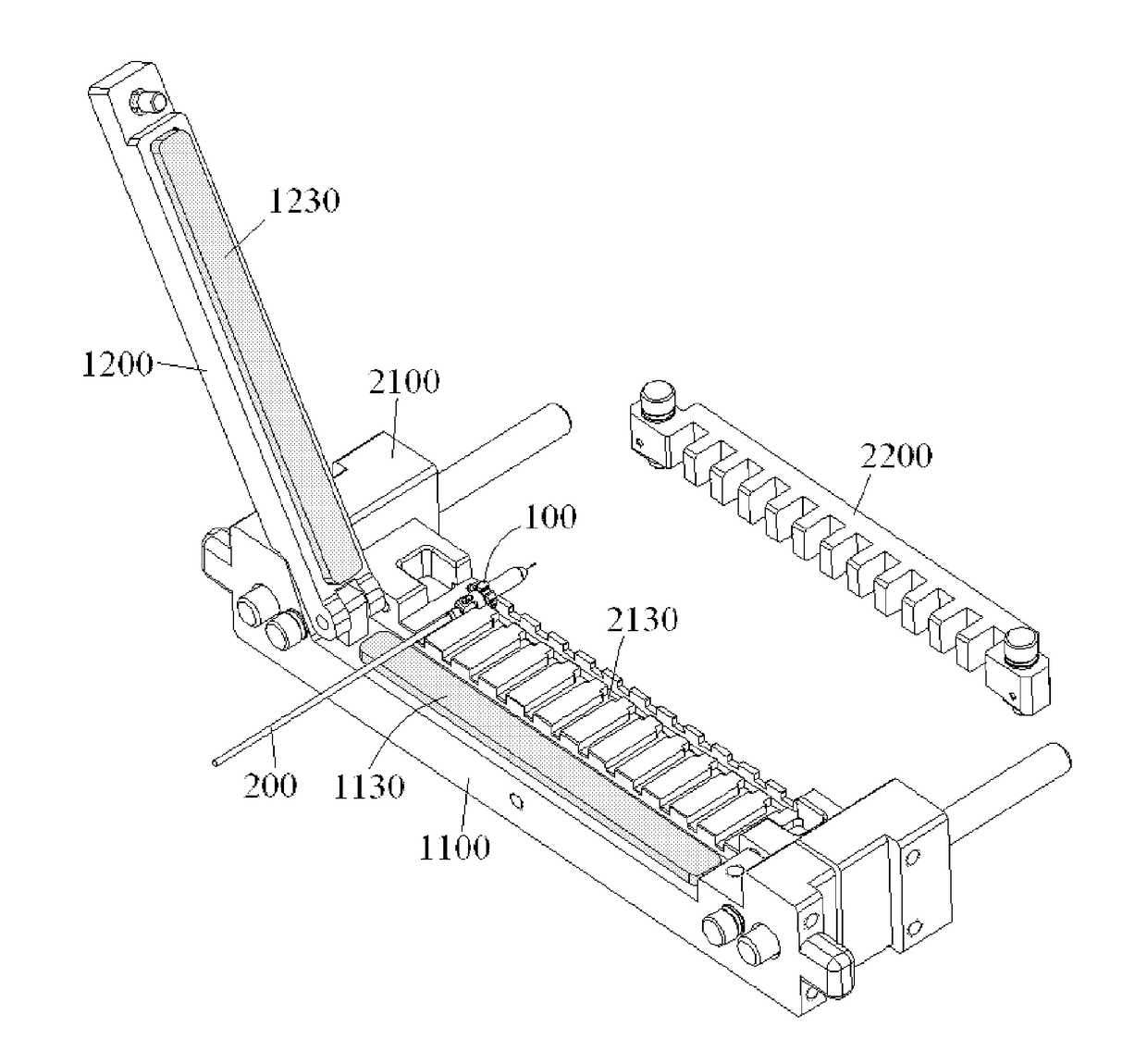

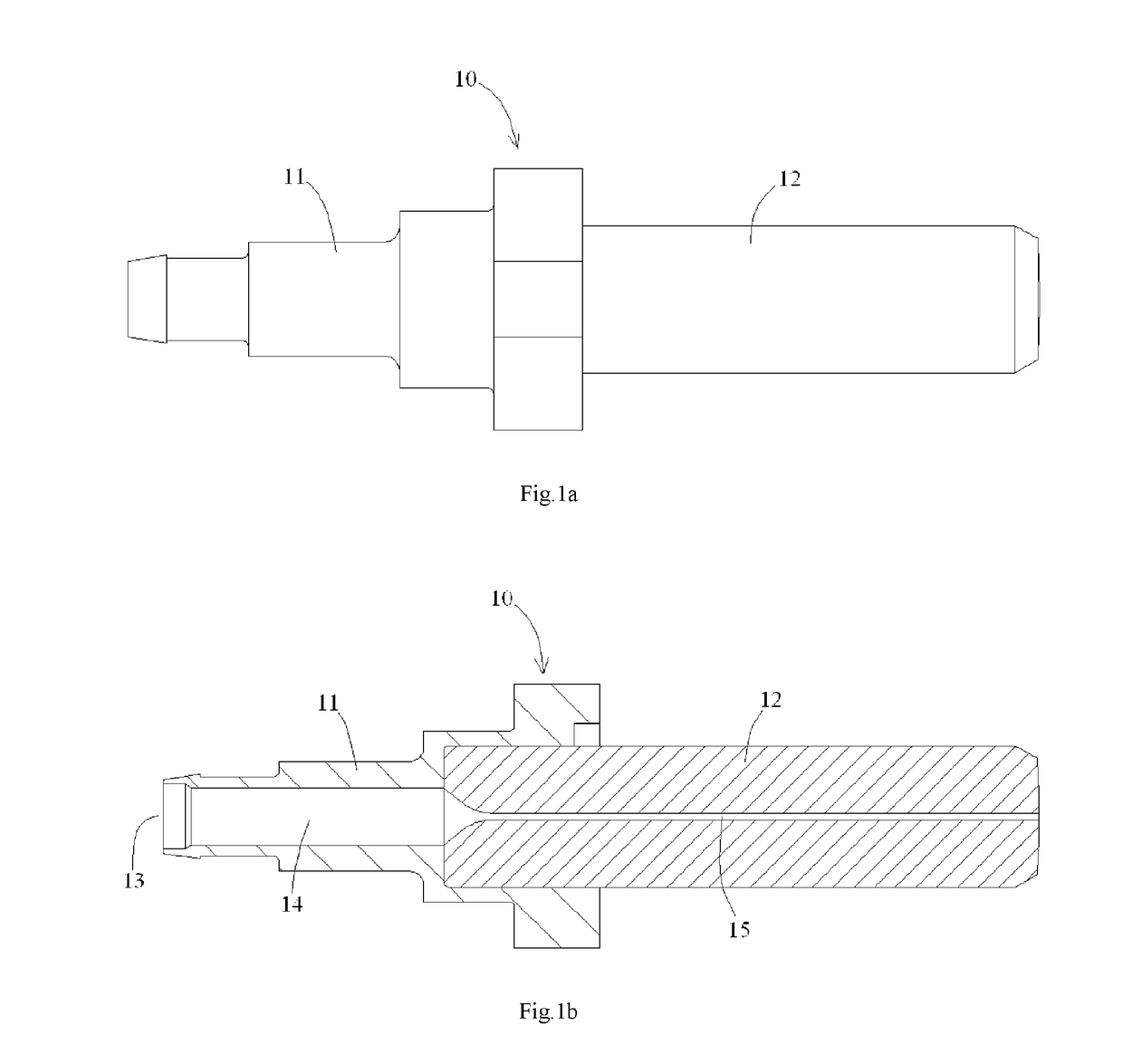

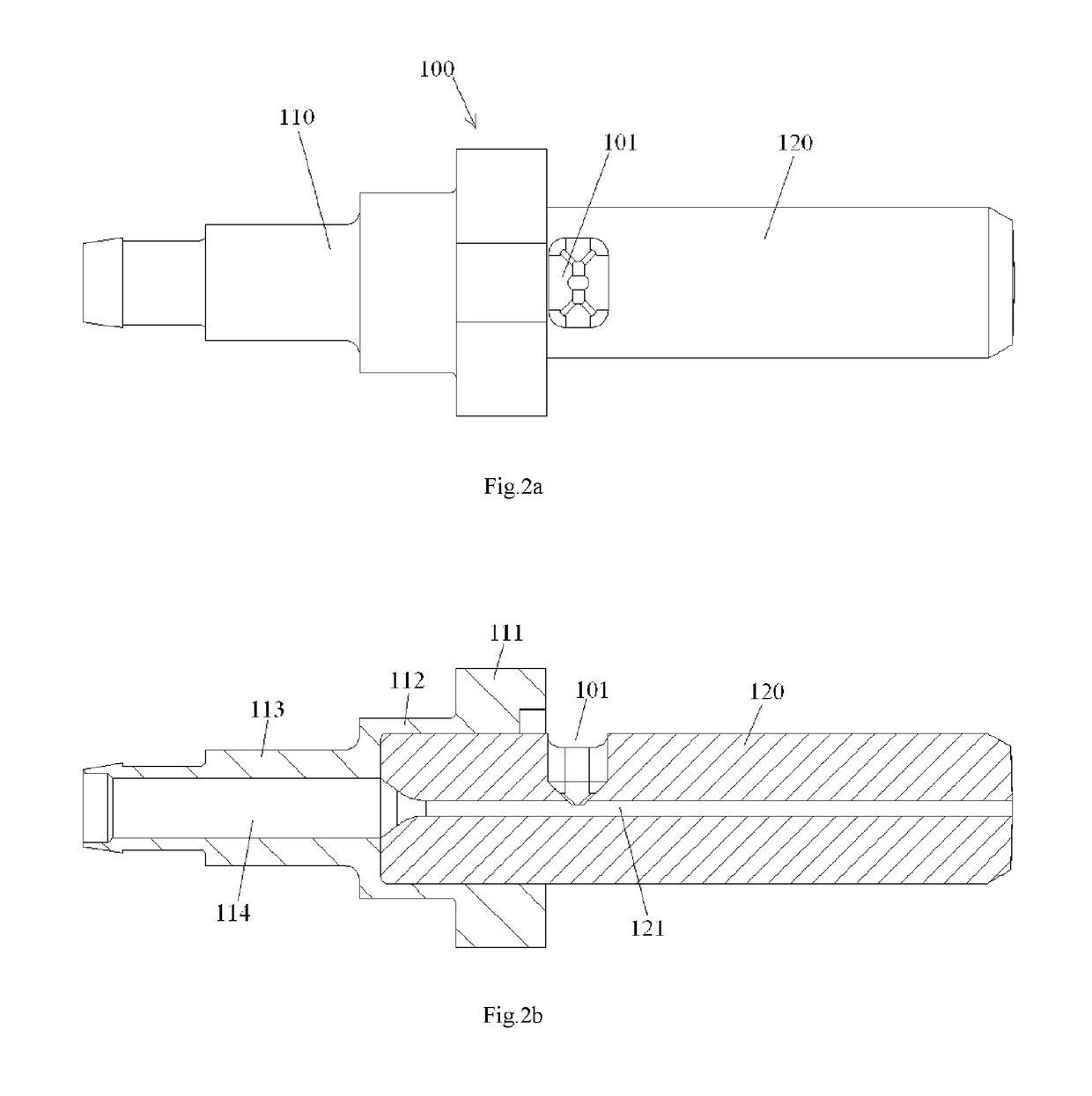

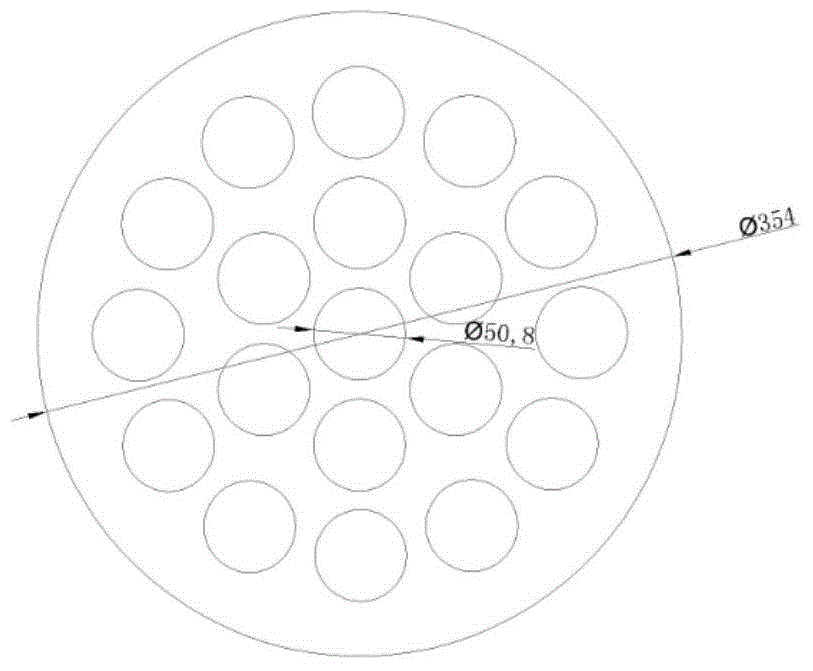

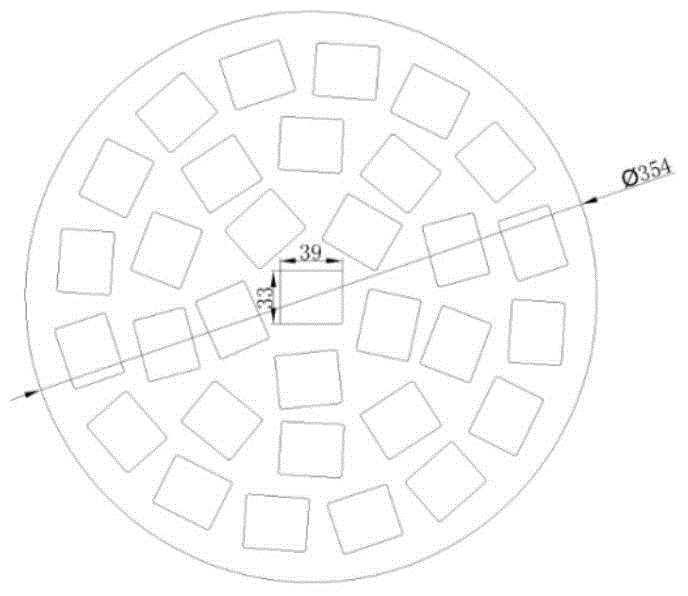

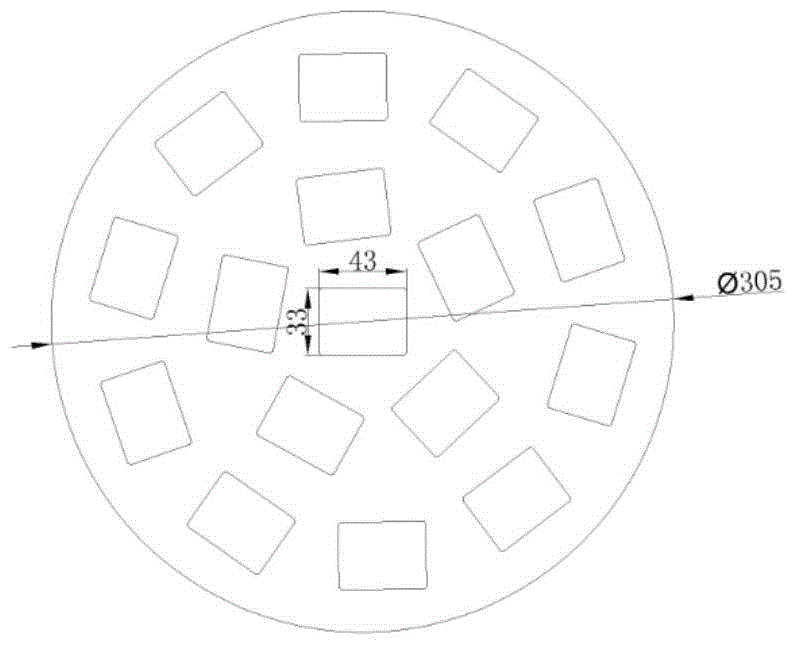

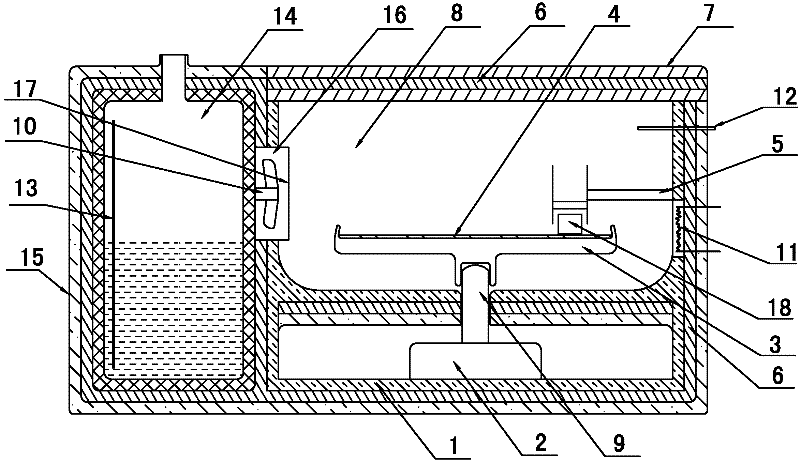

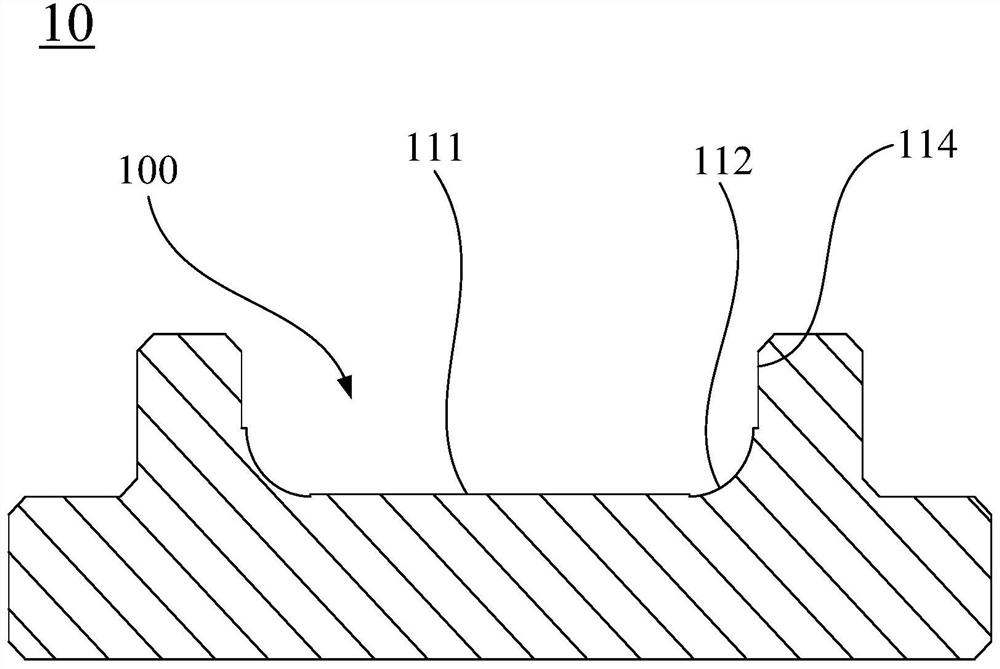

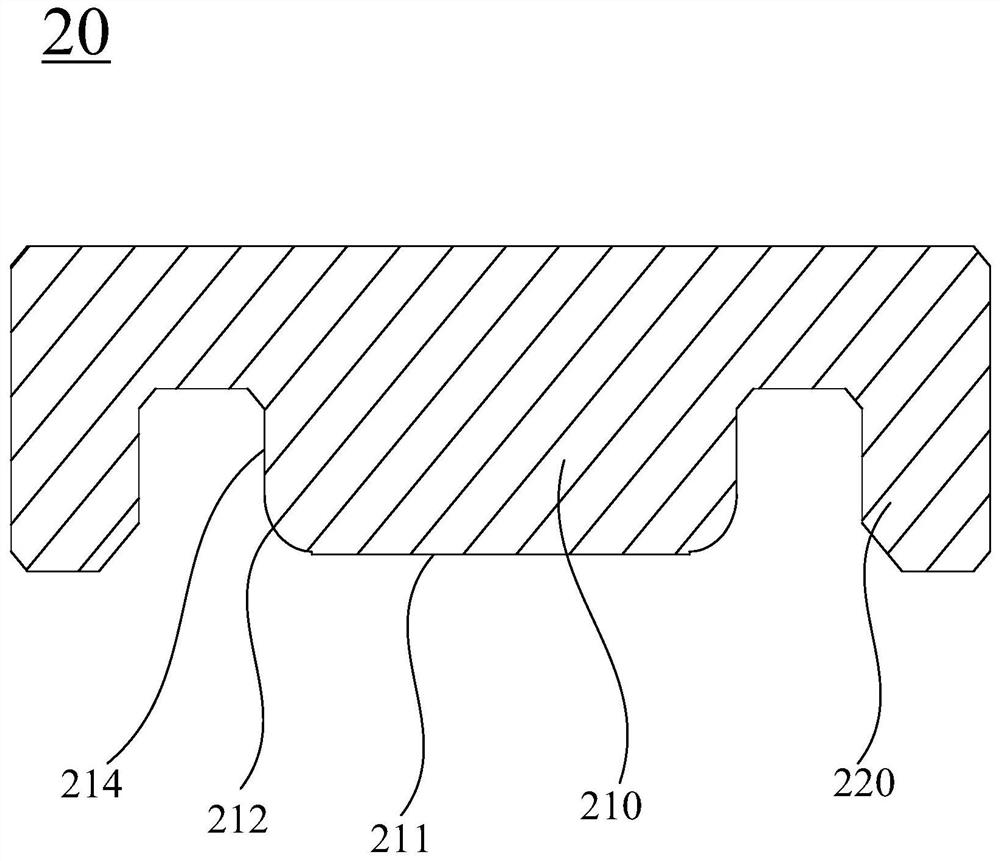

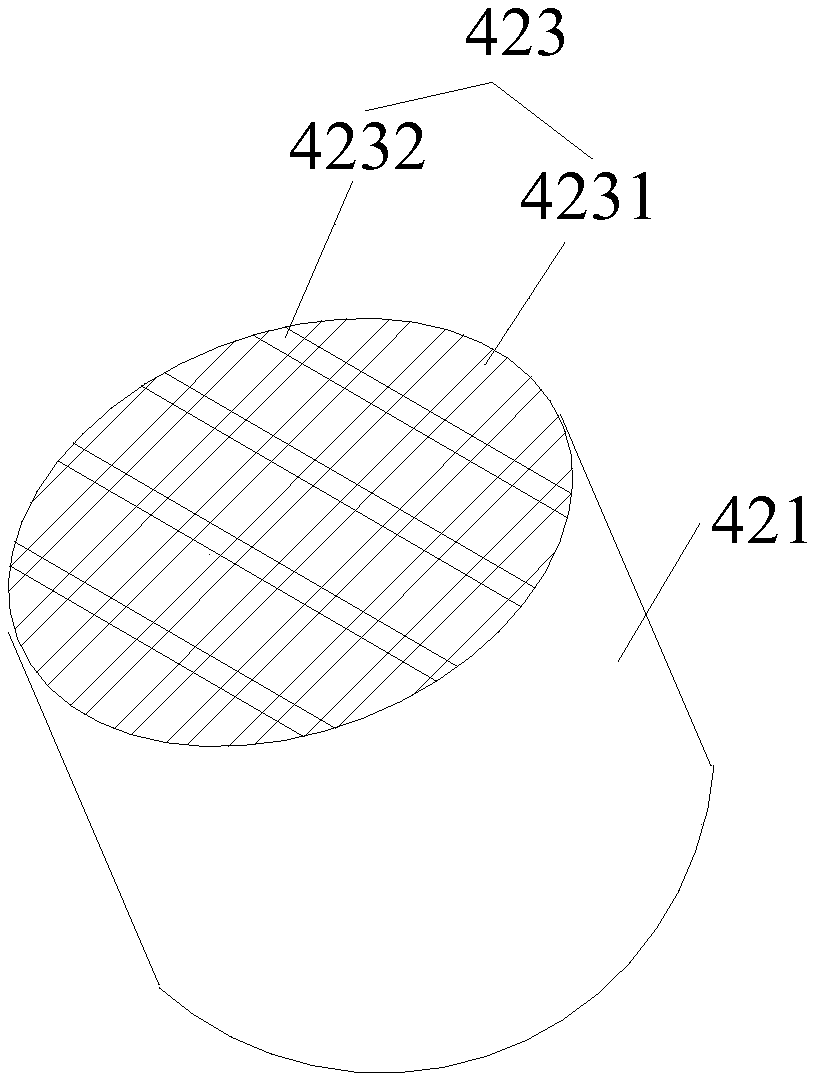

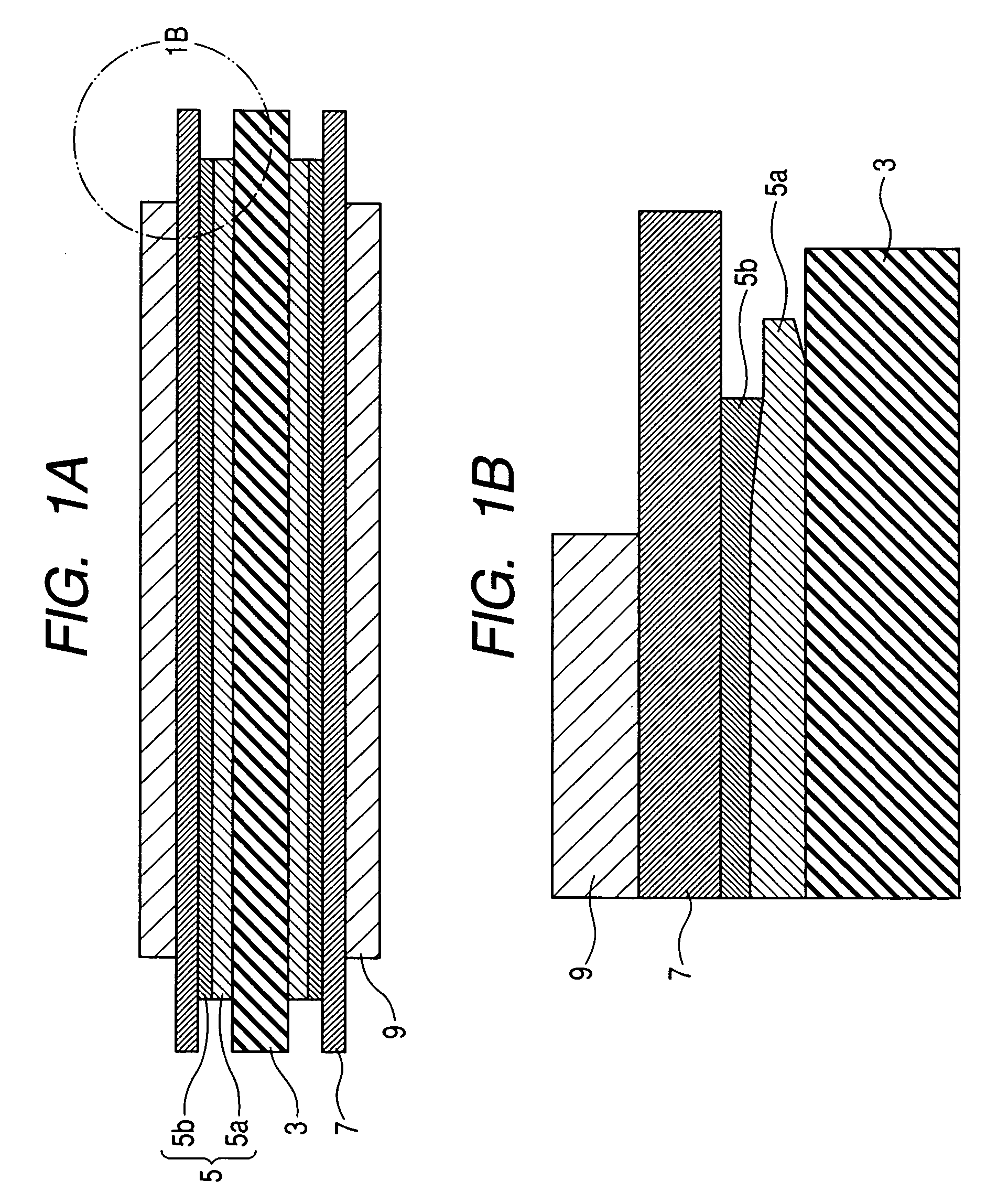

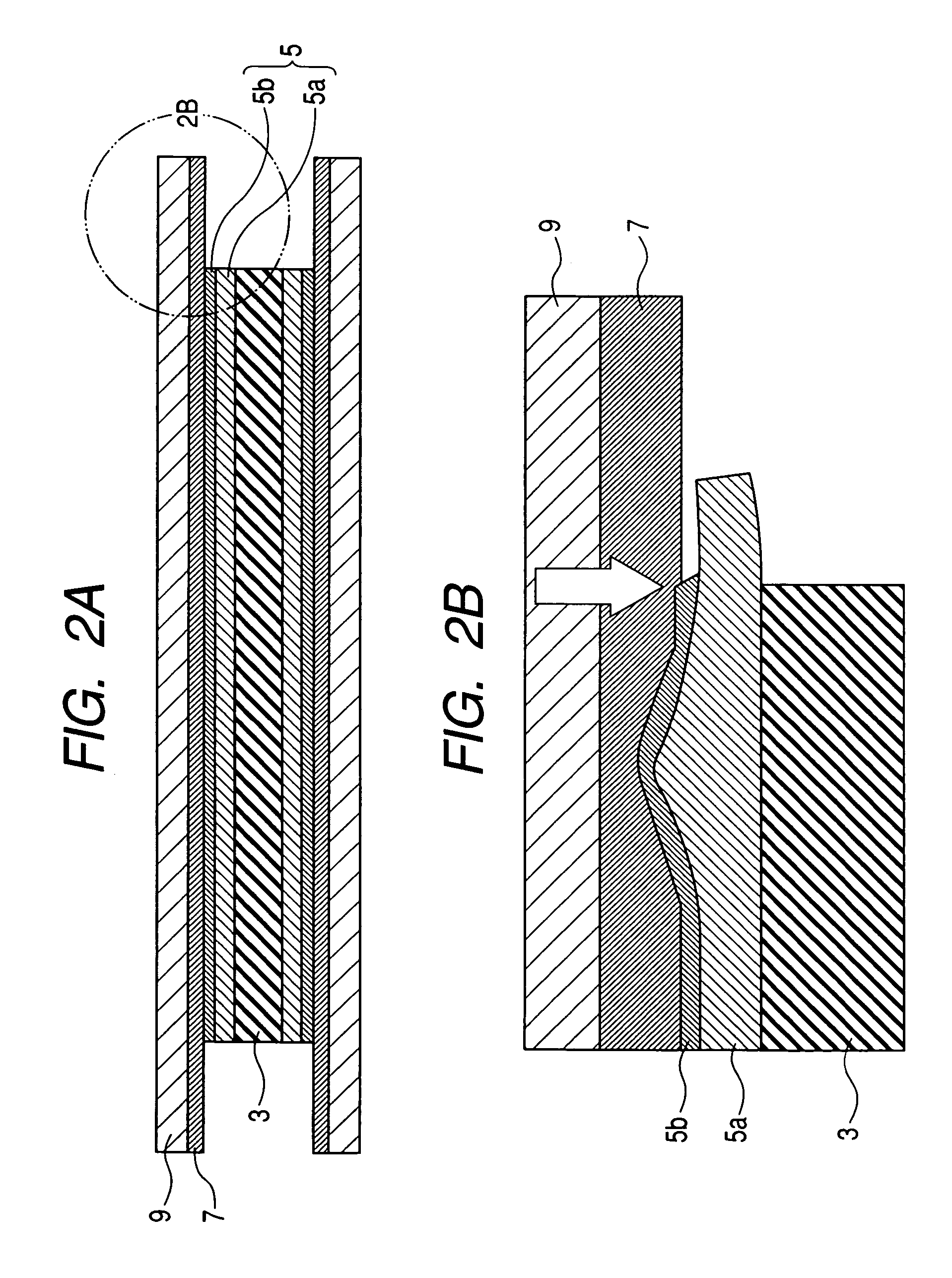

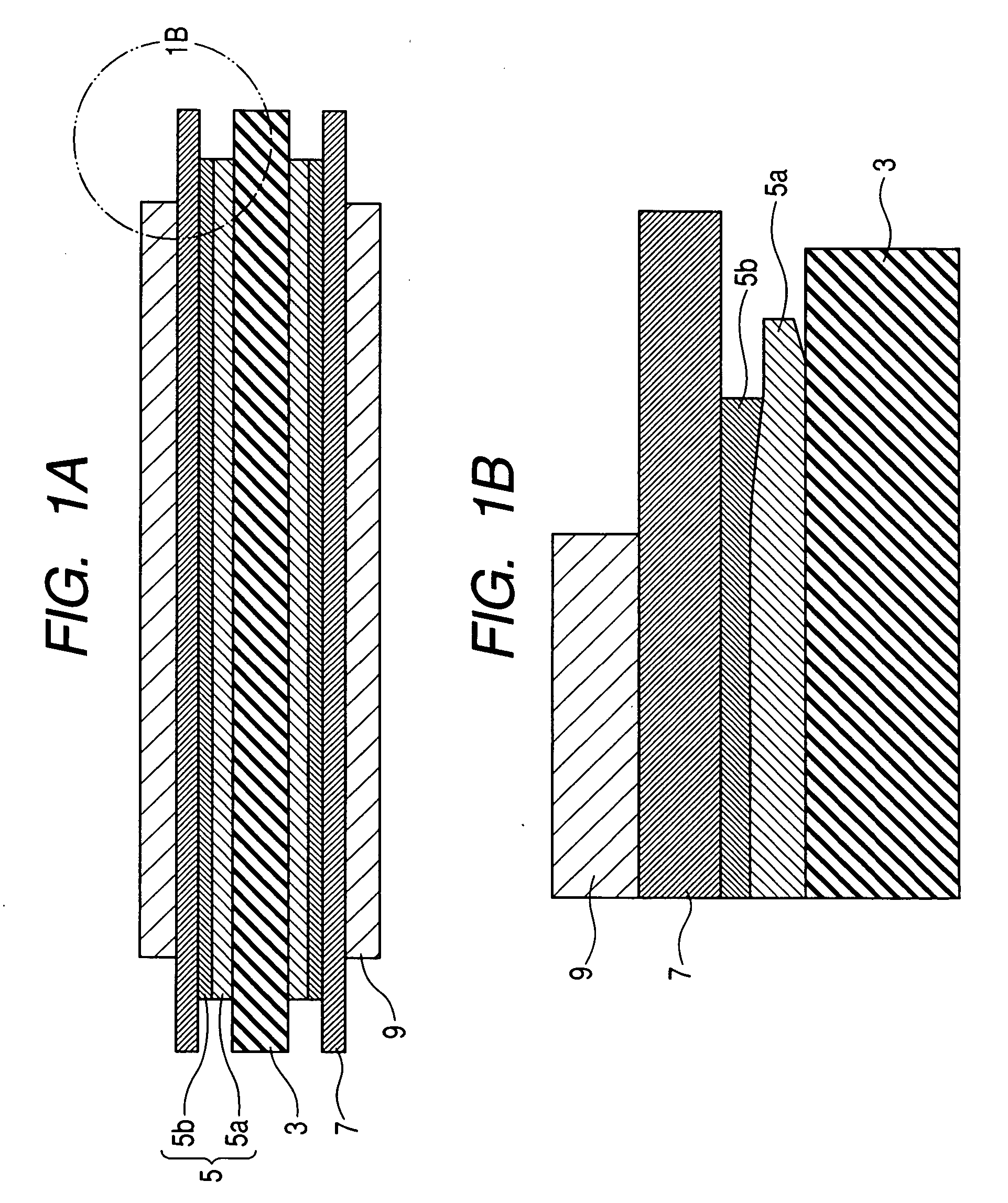

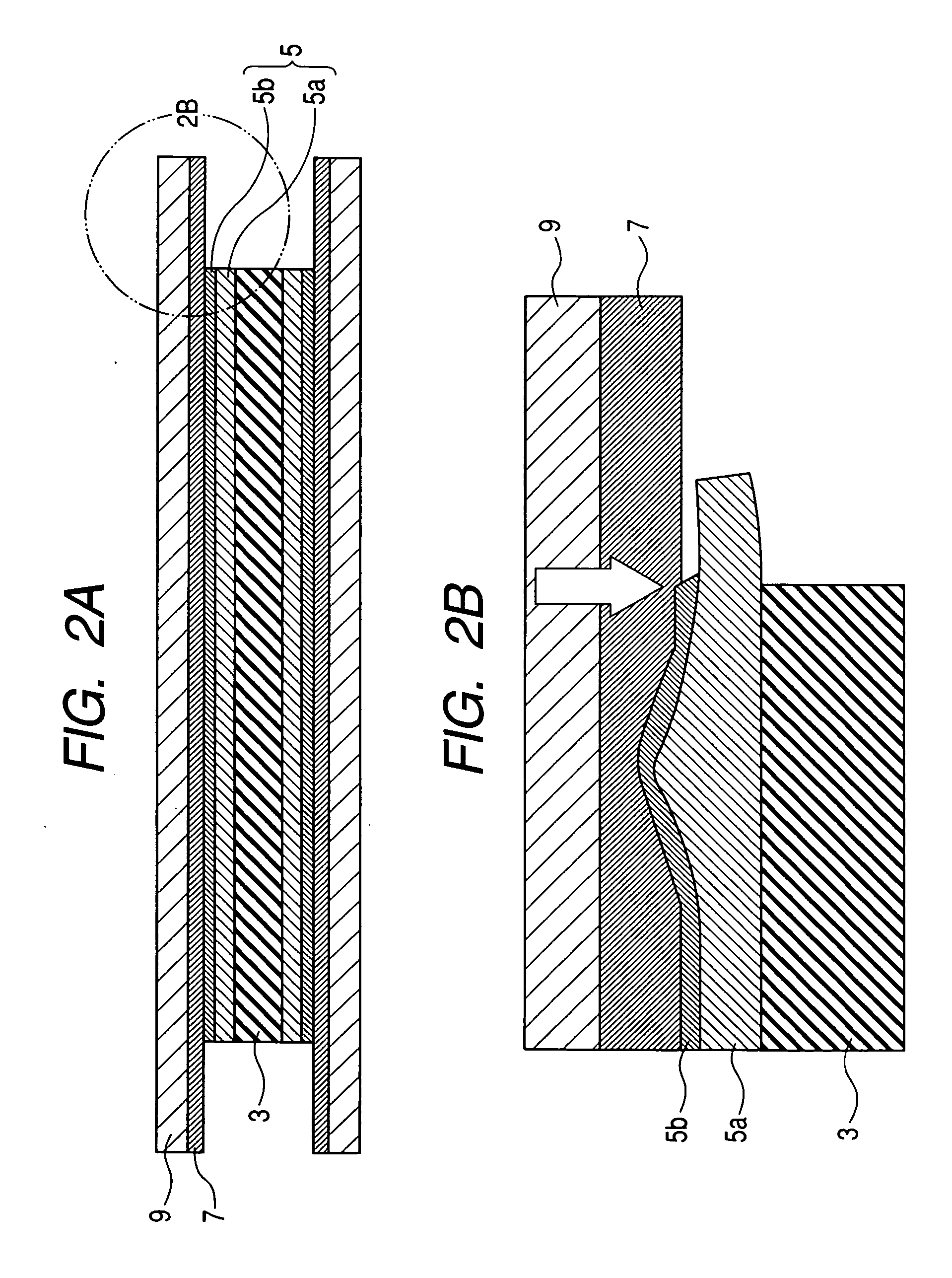

Ferrule device and method of manufacturing the same

InactiveUS20170139155A1Simple processEasily and smoothly inserted through ferruleCoupling light guidesFibre mechanical structuresFiberAdhesive

A method of manufacturing a fiber optic ferrule device, comprising steps of: providing a ferrule assembly; inserting a fiber into a fiber bore of the ferrule assembly until the fiber protrudes a predetermined distance from a front end surface of the ferrule assembly; and filling an adhesive into the ferrule assembly, so that the adhesive flows into the fiber bore and holds the fiber in place in the fiber bore after the adhesive is cured. The fiber is easily and smoothly inserted through the ferrule assembly, and the risk that the fiber is damaged by the adhesive is avoided. Also, the fiber protruding from the front end of the ferrule assembly is not adhered with any adhesive.

Owner:TYCO ELECTRONICS (SHANGHAI) CO LTD

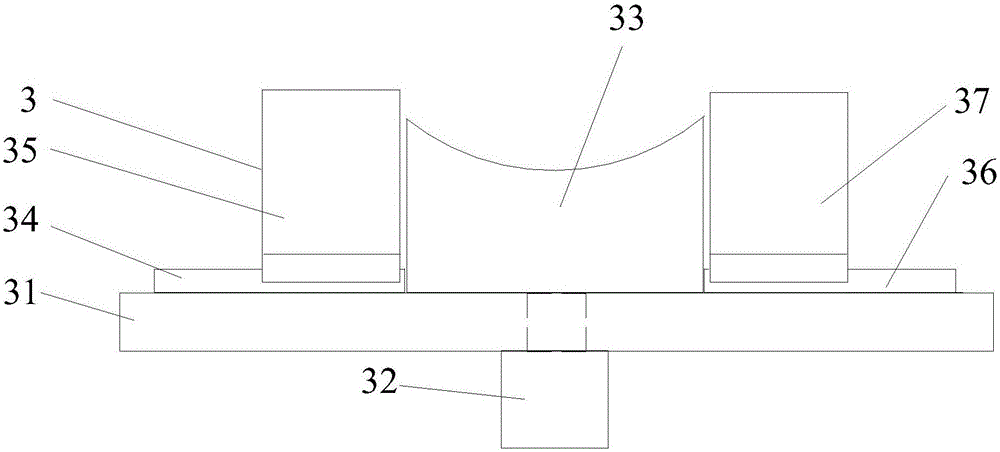

Non-wax polishing adsorption pad and manufacturing method thereof

The invention discloses a non-wax polishing adsorption pad and a manufacturing method thereof. The non-wax polishing adsorption pad comprises a grinding board, a first adhesive layer, an adsorption skin, a second adhesive layer, a supporting board and a gum layer, wherein the first adhesive layer and the second adhesive layer are each made of a hot melt adhesive film. The method includes the following production steps that firstly, the grinding board, the first adhesive layer, the second adhesive layer, the adsorption skin, the supporting board and the gum layer are cut to be of certain dimensions; secondly, the grinding board and the first adhesive layer are bonded to form a grinding layer composite board; thirdly, the first plane of the supporting board and the second adhesive layer are bonded, and the second plane of the supporting board and the gum layer are bonded, so that a supporting layer composite board is obtained; fourthly, a grinding layer processed board is obtained by processing and cutting the grinding layer composite board; fifthly, the supporting layer composite board and the adsorption skin are bonded to form an adsorption skin composite board; sixthly, the adsorption skin composite board and the grinding layer processed board are bonded to form an adsorption pad semi-finished product; and seventhly, edge cutting is carried out, specifically, the non-wax polishing adsorption pad is obtained by removing redundant portions.

Owner:ZHEJIANG WAZAM NEW MATERIAL CO LTD +1

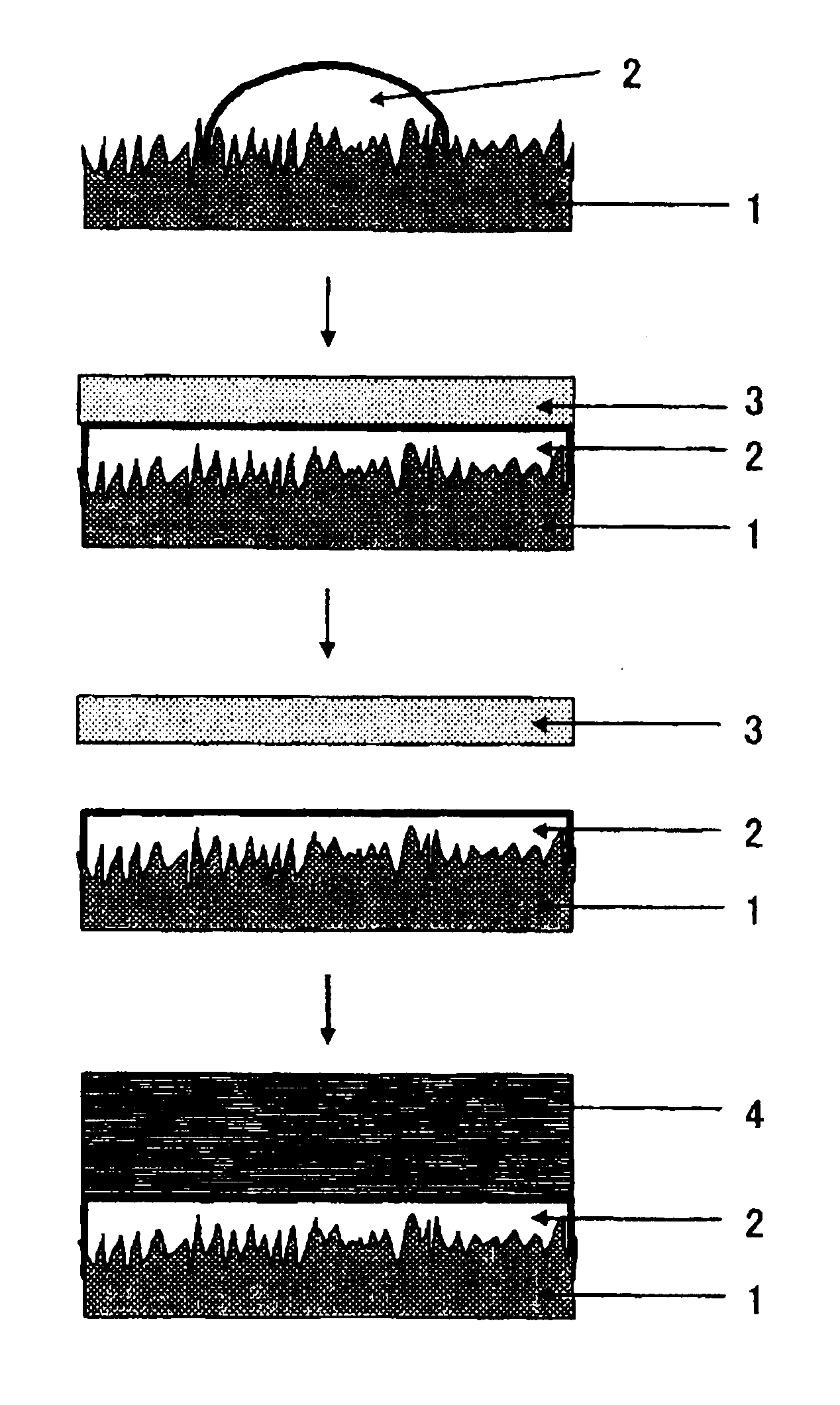

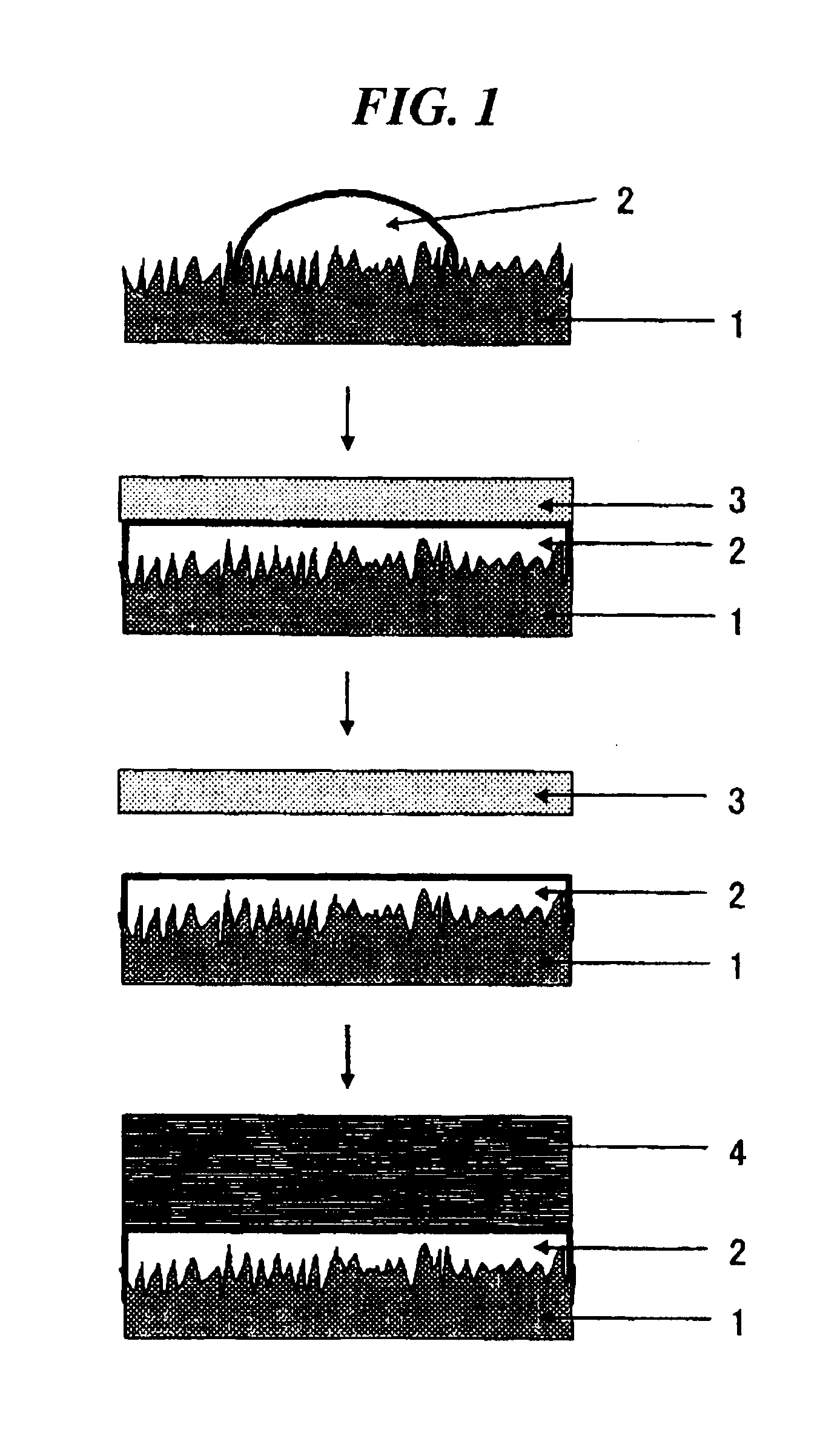

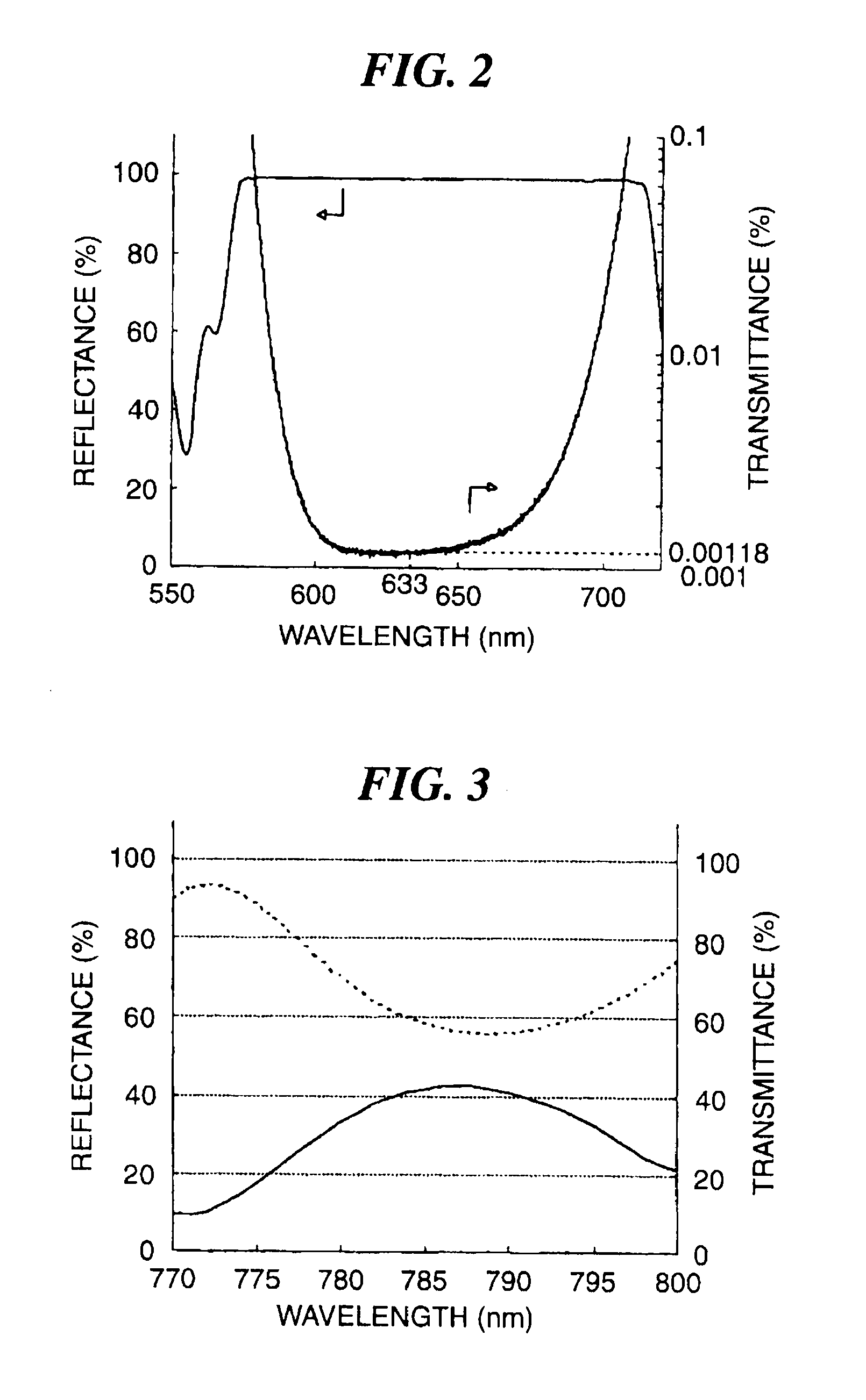

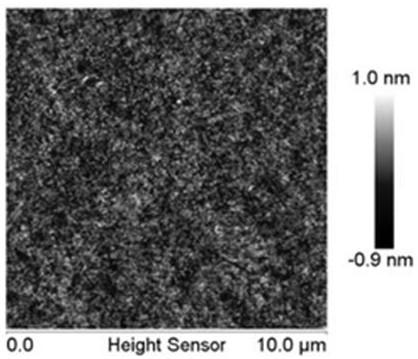

Optical component using composite substrate and process for producing same

InactiveUS20110039112A1Simple polishing processIncreased cost burdenPrismsVacuum evaporation coatingBeam splitterComposite substrate

A resin composition (2) such as a photo-curable resin composition or a heat curable or thermosetting resin composition is placed on an optical substrate (1). A printing pressure is applied to the side of the resin composition (2) of the optical substrate (1) with the resin composition (2) by means of an extra-flat pressing plate having a flatter plane than the optical substrate (1). The resin composition is cured by utilizing light or a temperature change to form a composite substrate. A thin film (4) such as a functional inorganic optical film, a dielectric multilayered optical thin film, or an optical functional metallic film is stacked on the composite substrate, for example, by low-temperature sputtering or ion beam sputtering to form an optical component such as a reflection mirror, a beam splitter, a band-pass filter, a band-stop filter, and an edge filter.

Owner:NAT INST OF ADVANCED IND SCI & TECH

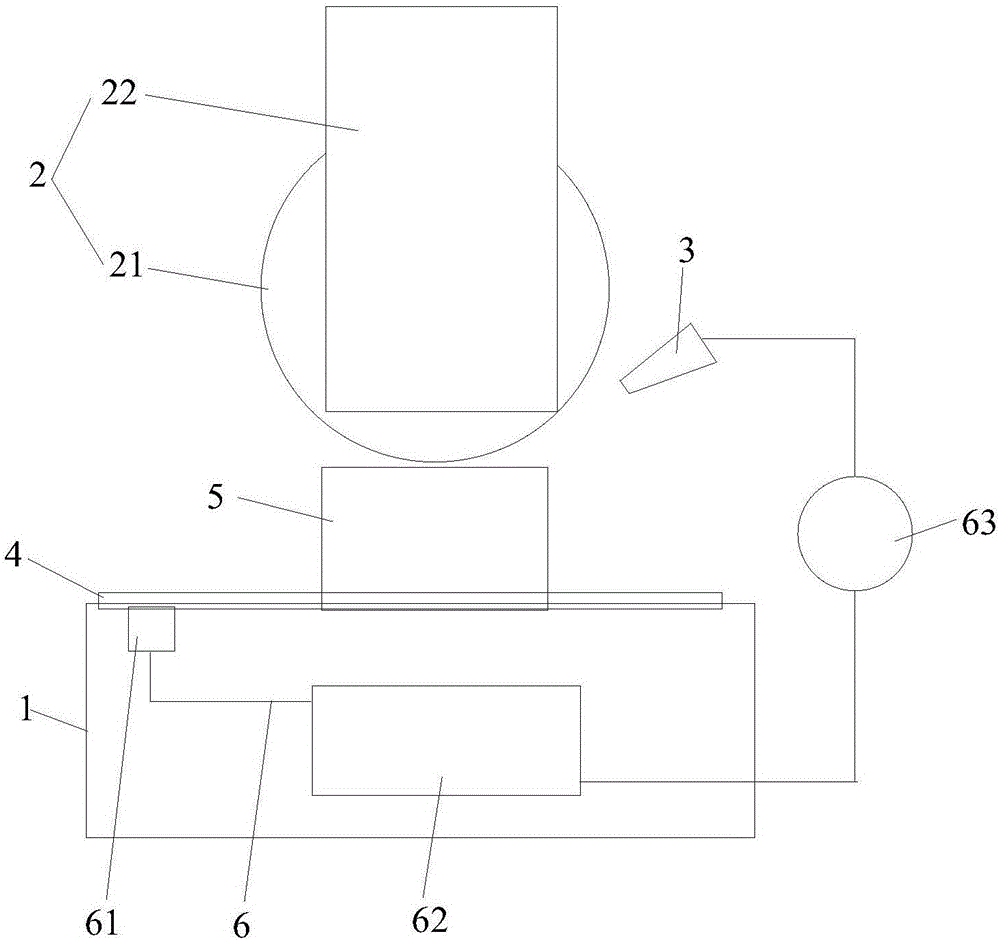

Prism polishing device

InactiveCN106625116AIncrease productivityImprove polishing rateOptical surface grinding machinesSpray nozzleMagnetorheological fluid

The invention discloses a prism polishing device. The device comprises a machine frame, a buffing wheel connecting the machine frame, a wheel drive device connecting the buffing wheel and driving the buffing wheel to rotate, nozzles for ejecting magnetorheological fluid, a workbench arranged on the machine frame, a lifting fixture arranged on the workbench and used for clamping the prism and a loop structure of magnetorheological fluid; the buffing wheel is arranged on the upper side of the lifting fixture, a recovery port of polishing liquid is arranged on the workbench, the recovery port of polishing liquid is connected with a collector of the loop structure of magnetorheological fluid, an outlet of the loop structure of magnetorheological fluid is connected with nozzles, the nozzles face towards the lifting fixture, the location of the nozzles is in coordination with the location of the buffing wheel and is in coordination with the location of the lifting fixture; the buffing wheel comprises a wheel body and a magnetic field generator sticking into the wheel body. By adopting the said structure, the prism polishing device is high in polishing efficiency and is suitable to be applied to industrial production; the manufacturing cost is low, and the requirement on experience or skill of the operating personnel for controlling the detection and the precision is low.

Owner:中山市光大光学仪器有限公司

A kind of surface treatment method of medical degradable metal interventional stent

ActiveCN106048707BAvoid harmReduce processing costsMetallic material coating processesInsertion stentCleansing Agents

The invention provides a surface treatment method for a degradable metal intervention stent, comprising the following steps: 1. performing sandblasting on the degradable metal intervention stent; 1. Ultrasonic cleaning treatment, and then vacuum drying; 3. Electrolytic polishing; 4. Submerging in deionized water and absolute ethanol for the second ultrasonic cleaning treatment, and then vacuum drying; 5. Passivation. The degradable metal interventional stent treated by the invention has good surface quality and high smoothness, can be placed in the atmosphere for a long time, and the corrosion resistance is significantly improved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Substrate diffusion and furbishing process

InactiveCN1464525AImprove performanceLow costSemiconductor/solid-state device manufacturingPhosphorSingle crystal

The invention discloses a N100 substrate diffusion and furbishing process, comprising phosphor pre-diffusion, phosphor primary diffusion, and using the single crystal sheet to make VDMOS tube. The process improves the product performance as well as reduces the cost for making, the diffusion and furbishing process is simple and applicable.

Owner:衡阳科晶微电子有限公司

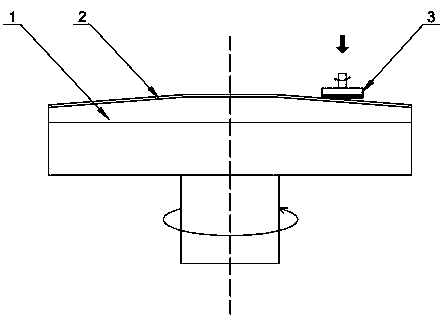

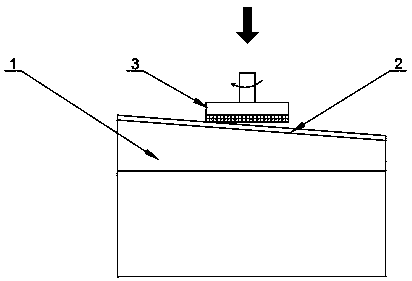

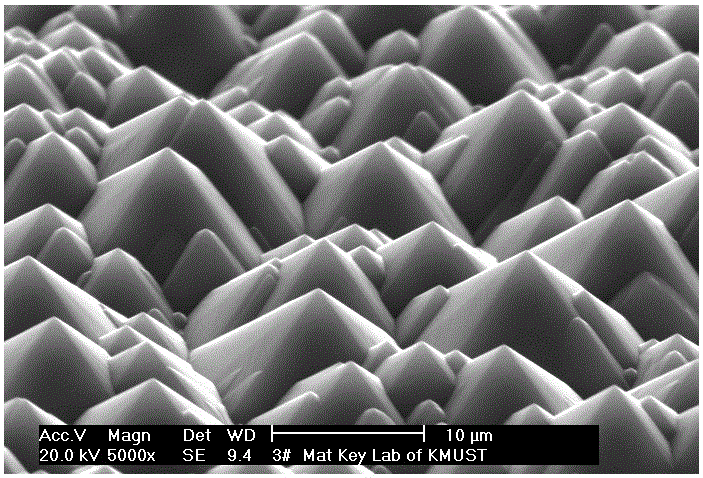

Polishing process for cadmium-zinc-cadmium wafer

InactiveCN110116340AAvoid scratchesAvoid Dark CracksLapping machinesWork carriersSurface roughnessEngineering

The invention discloses a polishing process for a cadmium-zinc-cadmium wafer. The polishing process comprises the following steps of grinding: grinding the cadmium-zinc-cadmium crystal by selecting afrosted puffed glass disc; milling: rotating a grinding wheel of a milling machine, removing a surface damage layer of the wafer, controlling the removal amount to be 80-150 microns and the surface roughness to be less than or equal to 20 nm, spraying cooling water between the wafer and the grinding wheel in the milling process, and transferring the wafer to a polishing procedure after processingis finished; and chemical-mechanical polishing: arranging the surface of a bearing disc to be in an inclined shape which is gradually lowered from the middle part of the disc to the circumference of the disc with an inclination angle to be 2 plus / minus 0.5 degrees, placing the cadmium-zinc-cadmium wafer on the bearing disc, adding a polishing solution with a pH value to be 9-11 in the chemical-mechanical polishing process, controlling a rotating speed of a grinding head to be 3-20r / min, the pressure to be 2-10N / cm2, the removal amount to be 20-40 microns and the time to be 20-40 min, and enabling the polishing solution to flow back and return to a polishing solution supply system after polishing is finished. The polishing process can effectively reduce scratches, scorings and cracks of thewafer, can reduce the surface roughness of the wafer and has a wide application prospect.

Owner:湖南大合新材料有限公司

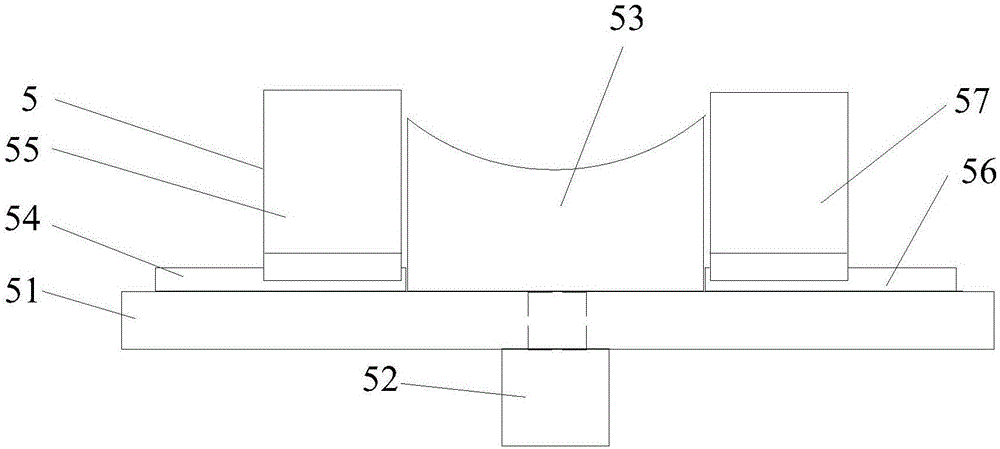

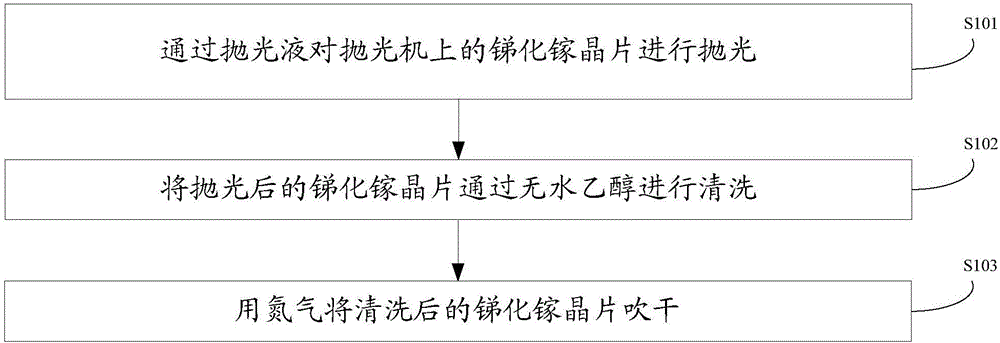

Polishing agent and method for polishing gallium antimonide wafer by employing polishing agent

ActiveCN106590439AHigh polishing removal rateNo chippingSemiconductor/solid-state device manufacturingPolishing compositions with abrasivesGallium antimonideEngineering

The invention discloses a polishing agent and a method for polishing a gallium antimonide wafer by employing the polishing agent. The polishing agent is high in speed of polishing and removing a gallium antimonide material; the polished wafer surface is glabrous and smooth; edge breakage and scaling off do not exist; the polishing technology is simple, artificial control factors are relatively few, the availability ratio is greatly improved, and the polishing agent and the method are beneficial to cost reduction.

Owner:11TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

Ultralow temperature polishing machine

The invention provides an ultralow temperature polishing machine which comprises a metal shell, an electromotor, a polishing disk with a taper sleeve, a polishing pad, a test sample fixing device and a top cover with a thermal insulating layer; the ultralow temperature polishing machine is characterized in that the ultralow temperature polishing machine is additionally provided with a draught fan, an electric heater, a temperature sensor, a liquid level sensor and a liquid nitrogen metal container with the thermal insulating layer, wherein the liquid nitrogen metal container is arranged on one side wall of the metal shell; the liquid level sensor is arranged inside the liquid nitrogen metal container; the temperature sensor and the electric heater are arranged on the side wall of the metal shell which is arranged in a working area; a window is arranged on the side wall of the metal shell in the working area which is close to the liquid nitrogen metal container; another window which corresponds to the window on the side wall of the metal shell is also arranged on the thermal insulating layer of the liquid nitrogen metal container; the draught fan is arranged on the outer wall of the liquid nitrogen metal container in space formed by the two windows; and a netted protective guard is arranged at the periphery of the draught fan. The ultralow temperature polishing machine has the advantages that the operation is safe, the polishing degree of materials is high, meanwhile, the scratch resistance capacity of the surface of the materials is increased and the subsurface damage is reduced.

Owner:SHANDONG UNIV OF TECH

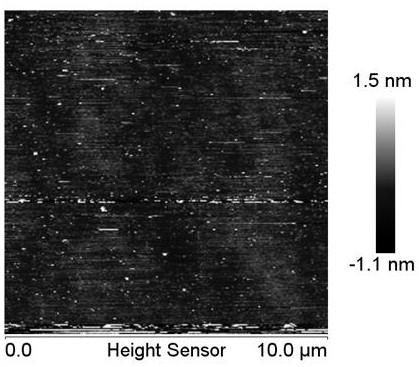

A polishing method for gallium antimonide single wafer

ActiveCN106064326BReduce surface damageEasy to cleanLapping machinesGallium antimonideSurface roughness

The invention discloses a polishing method for a gallium antimonide single crystal wafer. For coarse polishing, a cerium oxide polishing pad is adopted, and polishing liquid contains aluminum oxide abrasives with the particle size of W1, at the pressure of 100 to 200 g / cm<2>, the rotating speed of 10 to 40 r / min and the flow of 10 to 50 mL / min; for medium polishing, a black polyurethane polishing pad is adopted, and the polishing liquid contains silicon dioxide nano abrasives with the particle size of 60 to 100 nm and an oxidant, i.e., sodium hypochlorite, at the pressure of 80 to 150 g / cm<2>, the rotating speed of 60 to 100 r / min and the flow of 10 to 30 mL / min; for fine polishing, a black synthesized leather polishing cloth is adopted, and the polishing liquid is abrasive-free polishing liquid, at the pressure of 30 to 100 g / cm<2>, the rotating speed of 20 to 60 r / min and the flow of 5 to 10 mL / min. The polishing process is simple and easy to operate; the gallium antimonide single crystal wafer is low in surface damage and easy to clean, and the surface roughness is 0.3 nm.

Owner:CHINA ELECTRONICS TECH GRP NO 46 RES INST

Metal polishing method

InactiveCN109500721ASimple polishing processImprove polishing efficiencyEdge grinding machinesPolishing machinesPunch pressMetal

The invention discloses a metal polishing method. The metal polishing method comprises the following steps that S1, a cold rolled plate coil profile is subjected to annealing treatment, and an annealed profile is obtained; S2, the annealed profile is fed into a first grinding machine and subjected to primary chemical mechanical polishing through first polishing liquid, and a polished profile is obtained; S3, the polished profile is fed into a cleaning pool to be cleaned, and a product raw material is obtained; S4, the product raw material is fed into a blanking machine for blanking, and a primary product is obtained; and S5, the primary product is fed into the first grinding machine and subjected to secondary chemical mechanical polishing through second polishing liquid, and a finished product is obtained. The polishing technology is simple in process and high in polishing efficiency.

Owner:浙江宏泰精密科技有限公司

Magnesium alloy chemical polishing technology

The invention discloses a magnesium alloy chemical polishing technology, which comprises the steps of preparing a polishing solution, performing pre-treatment, performing chemical polishing and performing post-treatment to complete the chemical polishing technology on a magnesium alloy. The method comprises the following concrete steps: 1) preparing the polishing solution: adding 30-60 g of nitric acid, 20-60 g of oxalic acid and 1-5 g of sulfuric acid in 1 L of water, uniformly stirring the components to prepare the polishing solution; 2) performing pre-treatment: cleaning a magnesium alloy workpiece, removing the oil stain on the surface; 3) performing chemical polishing: placing the cleaned magnesium alloy workpiece in the polishing solution for immersion for 10-14 min; and 4) performing post-treatment: after polishing is completed, cleaning the workpiece by employing supersonic wave, and drying the workpiece. The technology has the advantages that by preparing the polishing solution in a reasonable mode, the polishing effect is greatly increased, and the polishing process is simple.

Owner:南通德益化工有限公司

Fixed abrasive polishing pad and dry type polishing method for deliquescent KDP crystals

ActiveCN112959233AAvoid damageIncrease profitPolishing machinesFlexible-parts wheelsPtru catalystChemical reaction

The invention discloses a fixed abrasive polishing pad and a dry type polishing method for deliquescent KDP crystals. The polishing method comprises the steps of polishing the KDP crystals by using the fixed abrasive polishing pad, and performing dry type fixed abrasive polishing without using a liquid polishing medium, wherein the fixed abrasive polishing pad comprises abrasive particles, reactants, a catalyst, a curing agent and a binding agent, the reactants in the polishing pad and the KDP crystals are subjected to a solid-phase chemical reaction, a generated transition layer is removed under the mechanical action of the abrasive particles, and a smooth surface is obtained. The method solves the problem that the KDP crystals are easy to deliquesce, improves the processing efficiency of the KDP crystals, simplifies the polishing process of the KDP crystals, and has the advantages of environmental friendliness, low cost and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

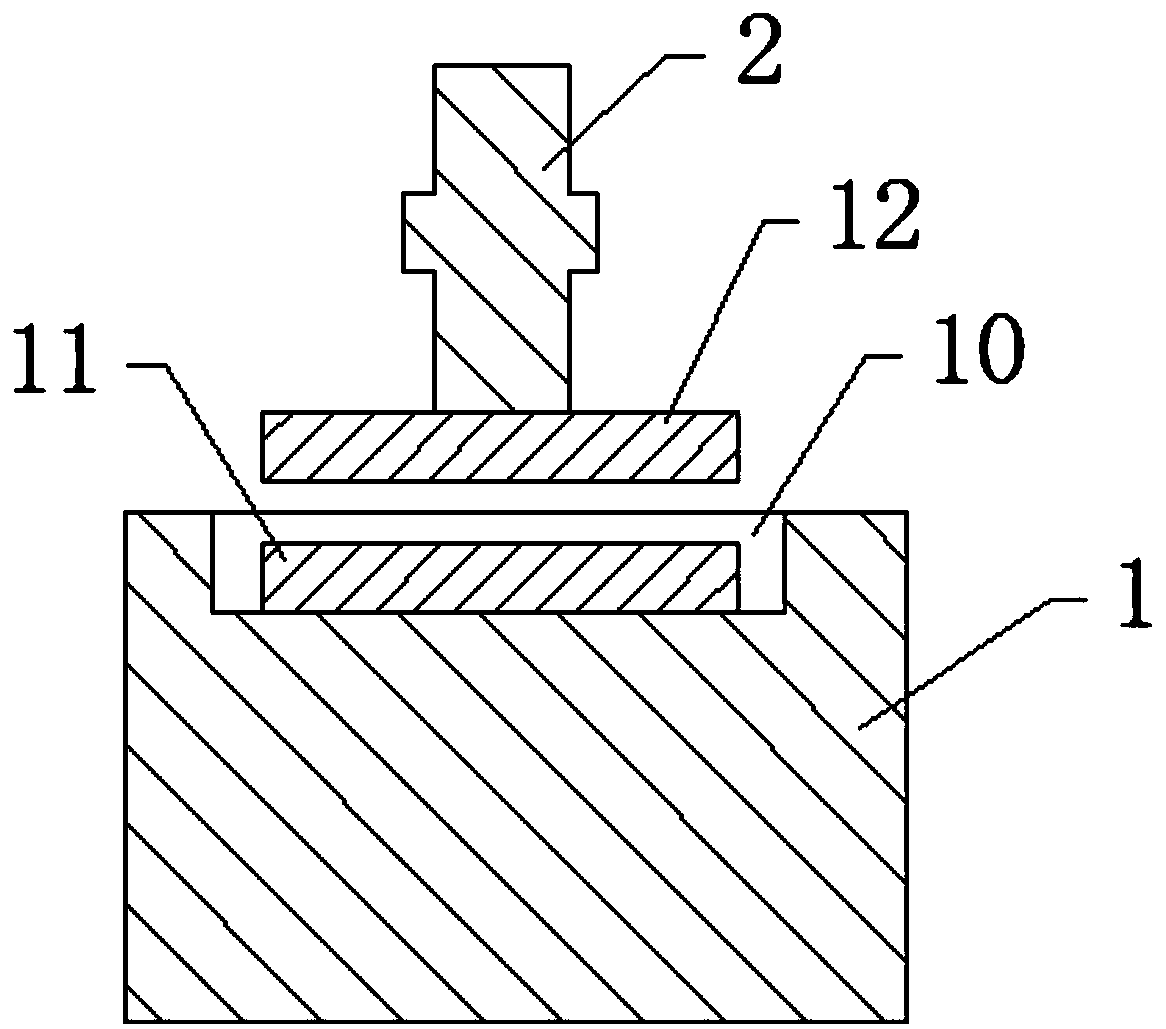

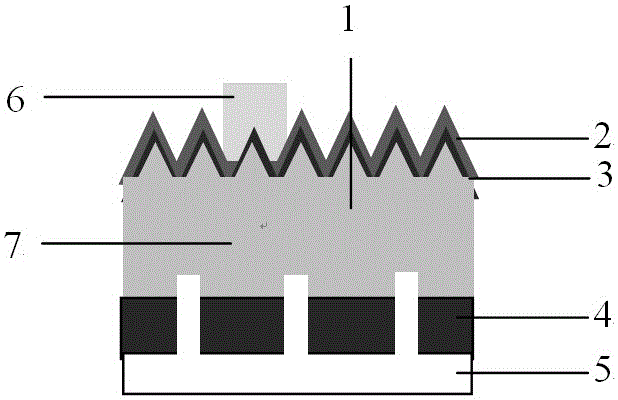

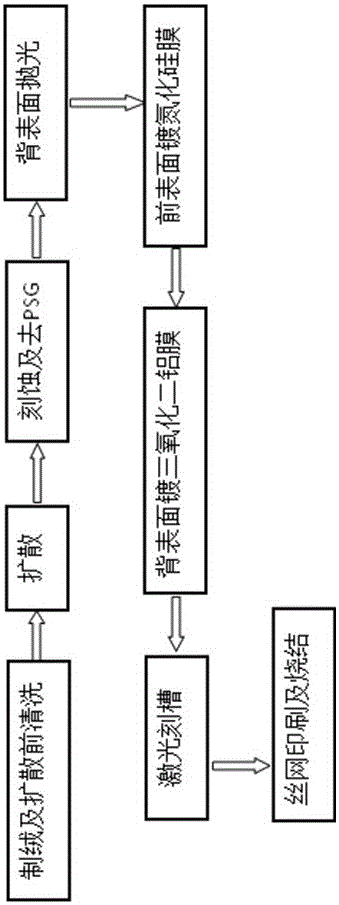

Manufacturing method of back surface polishing crystalline silicon solar battery

InactiveCN106057974AImprove photoelectric conversion efficiencyBack surface polished to achieveFinal product manufactureSemiconductor devicesScreen printingEtching

The invention discloses a manufacturing method of a back surface polishing crystalline silicon solar battery. The method comprises the following concrete steps: performing texturing and cleaning before diffusion; performing the diffusion; performing wet etching and PSG removal; plating a front surface with a silicon nitride film; plating a back surface with an alundum (Al2O3) membrane; performing laser groove etching; and performing screen printing and sintering. The method is characterized in that before the texturing and the cleaning before the diffusion, a back surface membrane plating process is also arranged, i.e., the back surface of an initial P-type silicon chip is plated with the silicon nitride film with a mask effect according to a conventional method. Compared to a conventional process, the method has the following advantages: only the back surface membrane plating process is added before a texturing and pre-diffusion cleaning process begins, at the same time, an individual back surface polishing process of the P-type silicon chip is omitted, back-surface polishing of the P-type silicon chip can also be realized, damage caused by the individual back surface polishing process to a solar battery N-type diffusion layer is avoided, and therefore, the photoelectric conversion efficiency of the crystalline silicon solar battery can be improved.

Owner:JIANGXI UNIV OF TECH

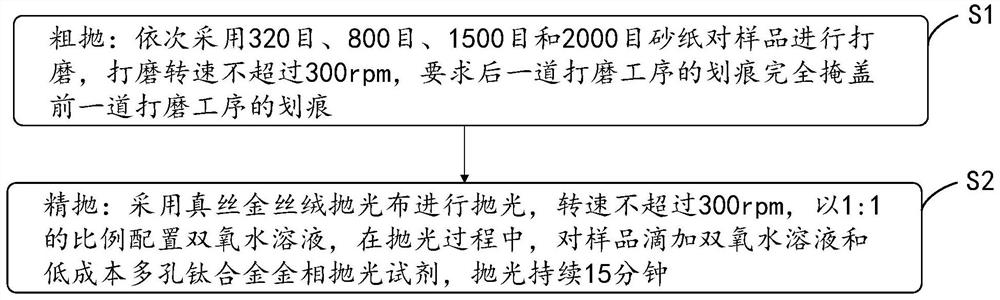

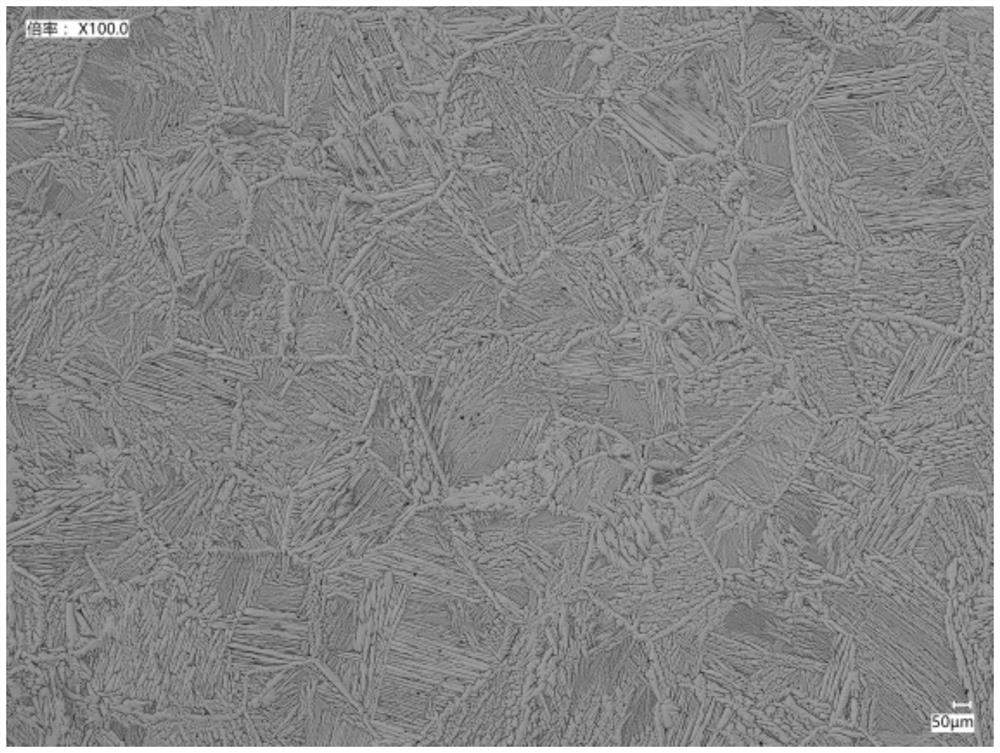

Low-cost porous titanium alloy metallographic polishing reagent and polishing process

The invention is applicable to the technical field of metallographic polishing, and provides a low-cost porous titanium alloy metallographic polishing reagent and a polishing technology.The low-cost porous titanium alloy metallographic polishing reagent comprises zirconium oxide powder, yttrium oxide powder or a reagent formed by mixing a mixture of the zirconium oxide powder and the yttrium oxide powder in any mass ratio with water, and the reagent is easy to prepare, low in cost and suitable for industrial production. The invention further provides a low-cost porous titanium alloy metallographic polishing technology, during rough polishing, deformation twin crystals can be avoided by limiting the polishing rotating speed, and during fine polishing, the low-cost porous titanium alloy metallographic polishing reagent is used, so that the corrosion effect is not affected, and the corrosion effect is not affected. And during polishing, the metallographic observation surface is not colored, the corrosion effect is not affected, the technological process is simple, the application range is wide, and the method is not limited to titanium alloy.

Owner:SHENZHEN ELEMENTPLUS MATERIAL TECH CO LTD

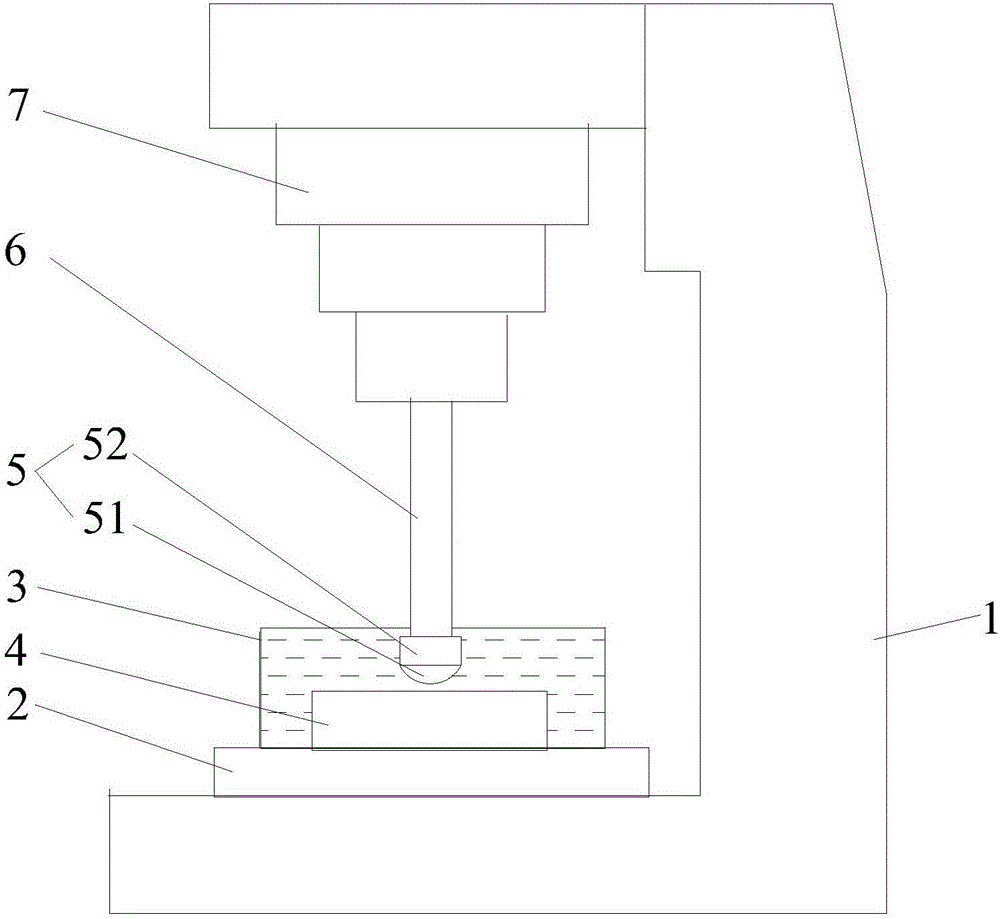

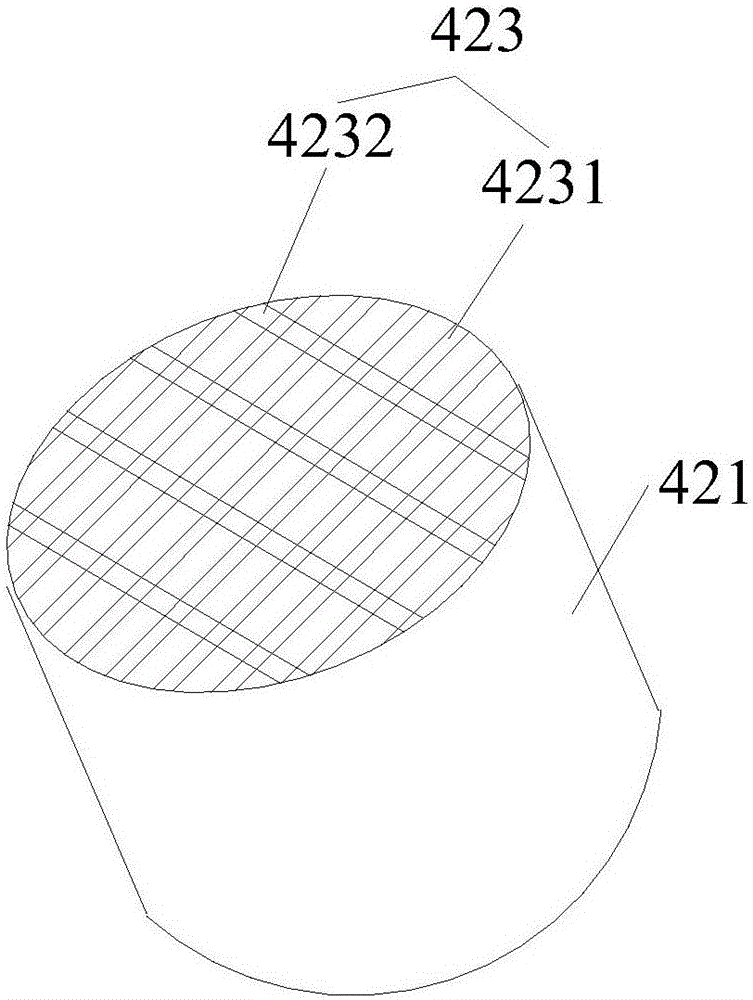

Equipment for prism polishing

InactiveCN106541312AHigh gloss mirror effectImprove polishing efficiencyOptical surface grinding machinesPrismEngineering

The invention discloses equipment for prism polishing. The equipment comprises a machine frame, a workbench, a plastic vessel, a lifting jig, a polishing tool, a lifting device and a main shaft, wherein the workbench is arranged on the machine frame, the plastic vessel is arranged on the workbench and used for containing magnetorheological polishing fluid, the lifting jig is arranged in the plastic vessel, the polishing tool is located above the lifting jig and matched with the lifting jig, the lifting device is used for driving the polishing tool to ascend or descend, and the main shaft is connected with the machine frame. The polishing tool is connected with the main shaft through the lifting device, the polishing tool comprises a polishing head, a sleeve and a magnet, the polishing head is sleeved with the sleeve, the magnet is arranged in the sleeve, and the magnet is connected with the polishing head so as to form a magnetic field on the surface of the polishing head. By the adoption of the structure, the polishing efficiency is high, the polishing process is simple and easy to operate, and the equipment is suitable for being used in industrial production; and the machining cost is low, the detection and precise control requirements are low, and the requirements for experience or skills of operators are low.

Owner:中山市光大光学仪器有限公司

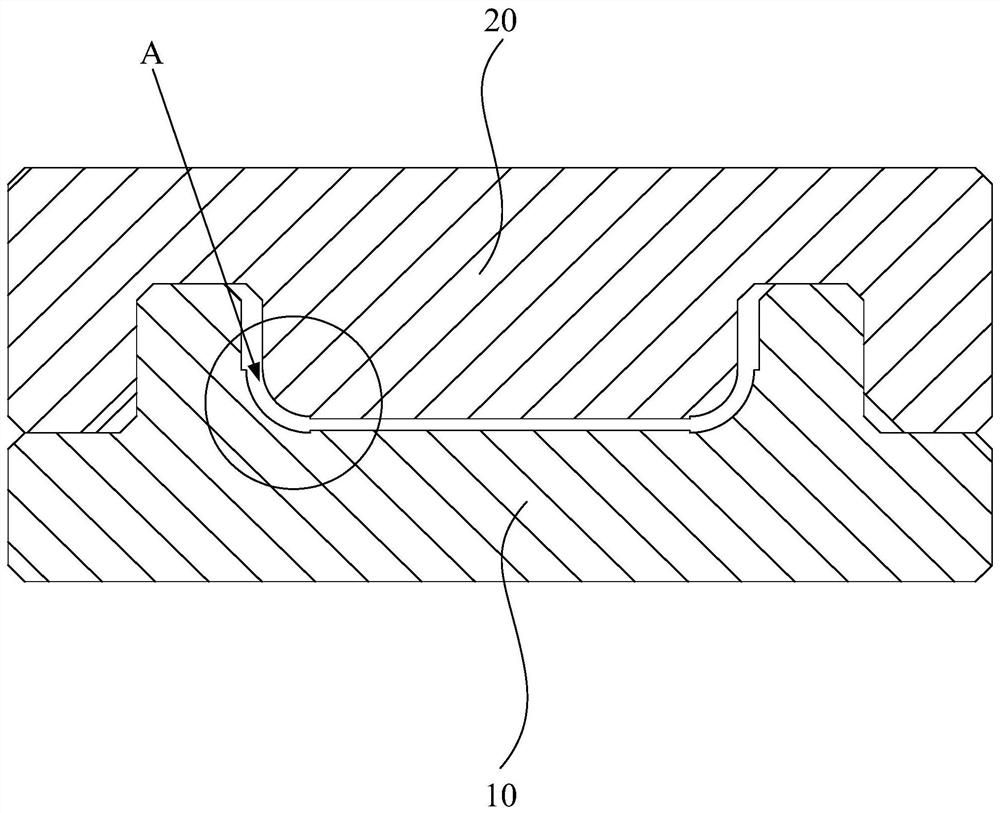

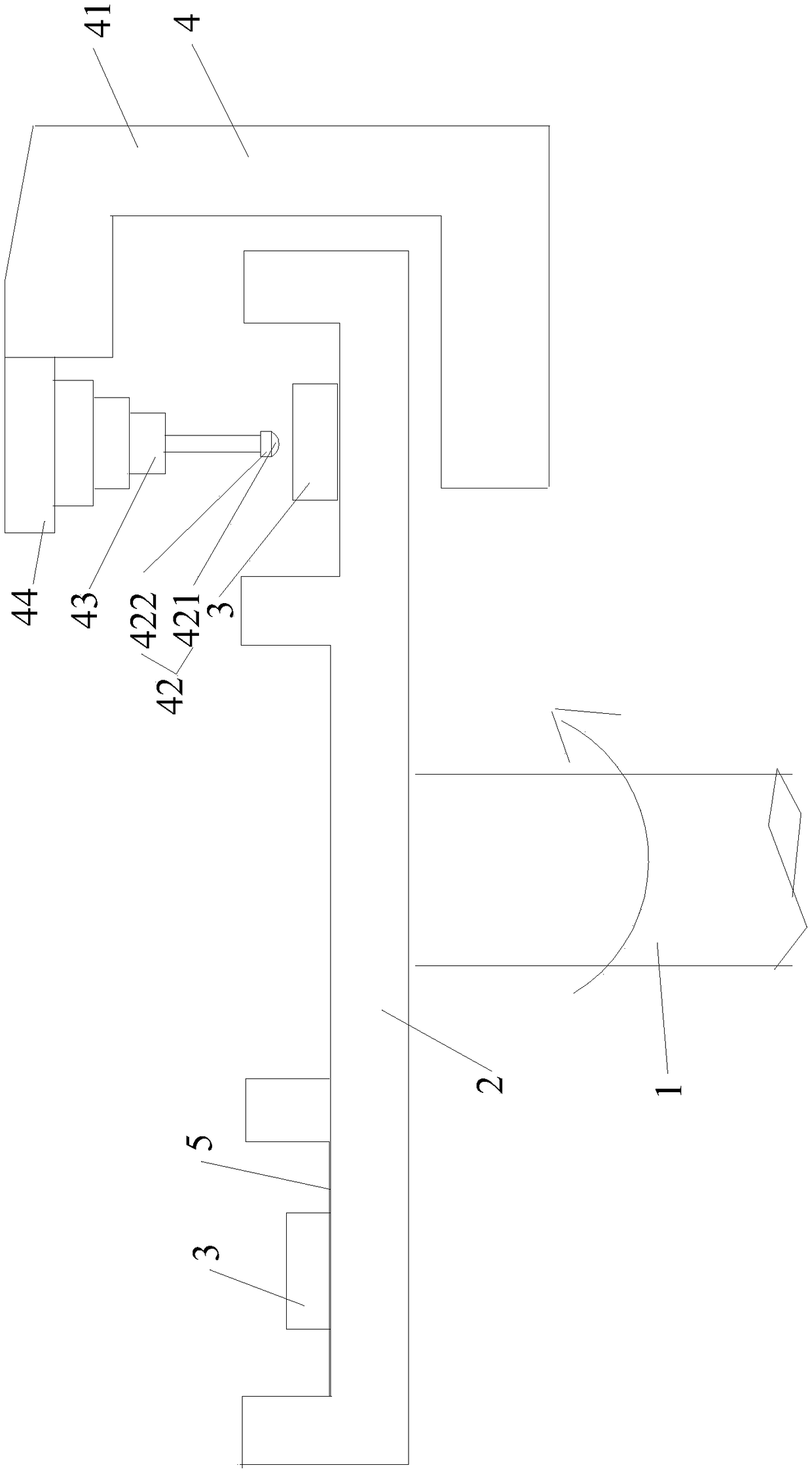

Glass forming mold, glass forming device and forming method

ActiveCN113060930AAvoid oxidation powdeAvoid the situationGlass reforming apparatusGlass productionFlat glassGlass forming

The invention provides a glass forming mold and a glass forming method. The glass forming mold comprises a shaping mold and a pressing mold which are matched for use; the shaping mold is provided with a shaping groove, and the bottom of the shaping groove is provided with a groove bottom plane area and a groove bottom curved surface area extending outwards in the groove opening direction along the edge of the groove bottom plane area; a pressing mold is provided with a shaping convex block, the top of the shaping convex block is provided with a convex block plane area and a convex block curved surface area, the convex block plane area is matched with the groove bottom plane area, the convex block curved surface area is matched with the groove bottom curved surface area, and when the shaping mold is matched with the pressing mold for use, the shaping convex block extends into the shaping groove; and the distance d1 between the groove bottom plane area and the protruding block plane area is 90%-99% of the thickness d of the plate glass to be processed, and the distance d2 between the groove bottom curved surface area and the protruding block curved surface area is larger than d. By adopting the glass forming mold, the subsequent processing and preparation time of the curved glass prepared by the glass forming mold can be remarkably shortened.

Owner:QINGYUAN CSG NEW ENERGY SAVING MATERIALS CO LTD +1

Magnesium alloy chemical polishing technology

The invention discloses a magnesium alloy chemical polishing technology. Through the steps of preparing a polishing solution, conducting pretreatment, conducting chemical polishing and conducting post-treatment, the magnesium alloy chemical polishing technology is completed. The magnesium alloy chemical polishing technology comprises the specific steps of preparing the polishing solution, wherein25-80 g of nitric acid, 20-60 g of oxalic acid and 2-10 g of hydrochloric acid are added to 1 L of water, the mixture is evenly stirred, and the polishing solution is prepared; conducting pretreatment, wherein a magnesium alloy workpiece is washed, and surface oil dirt is removed; conducting chemical polishing, wherein the washed magnesium alloy workpiece is placed in the polishing solution for dipping, and the dipping time is 10-14 minutes; and conducting post-treatment, wherein after polishing is ended, ultrasonic waves are used for cleaning the workpiece, and the workpiece is dried. The magnesium alloy chemical polishing technology has the advantages that through the reasonably prepared polishing solution, the polishing effect is greatly improved, and the polishing technology is simple.

Owner:NANTONG ITALMATCH CHEM

Manufacture method of non-aqueous printing ink wet underglaze colour self-sharpening polishing ceramic glazed tile

The invention relates to a manufacture method of a non-aqueous printing ink wet underglaze colour self-sharpening polishing ceramic glazed tile. The manufacture method is characterized by comprising the following steps of proportioning raw materials, ball milling, iron removal, spraying pulverizing, compacting for moulding, biscuiting, wet underglaze colour decoration, glaze firing, self-sharpening polishing and edging. The self-polishing is as below: in order to prevent passivation of a resin polishing grinding head on a smooth glaze, during normal polishing operation, a ceramic glazed tile product to be polished is added with a rough surface body to be polished; the rough surface body to be polished rubs the polishing grinding head to keep the grinding head sharp. The method has advantages that produced polishing ceramic glazed tile has high strength, brilliant color, rich pattern texture of a ceramic tile as well as high surface flatness and good glossiness of a polishing product. Meanwhile, a production technology has advantages of simple process, low production cost, short sintering period, low energy consumption and simple polishing technology, and is suitable for large-scale production and demand of common consumers.

Owner:FOSHAN SANSHUI NEW PEARL CONSTR CERAMICS IND +2

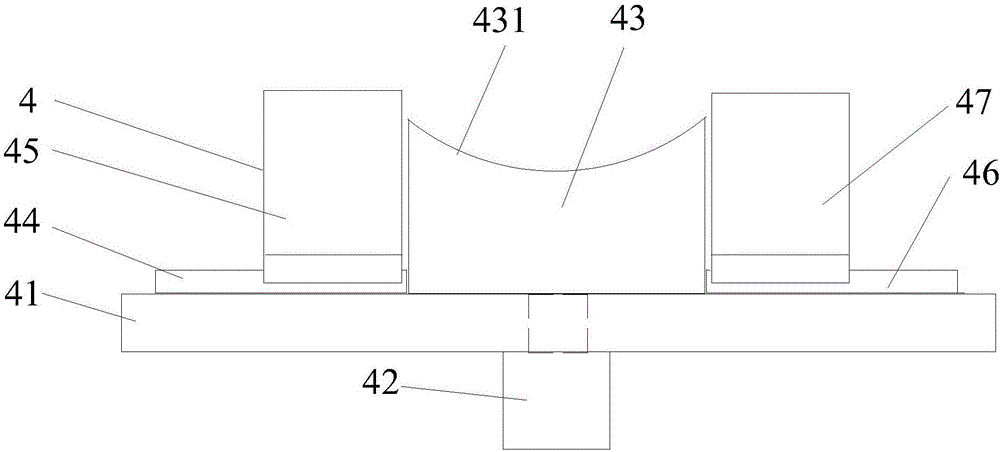

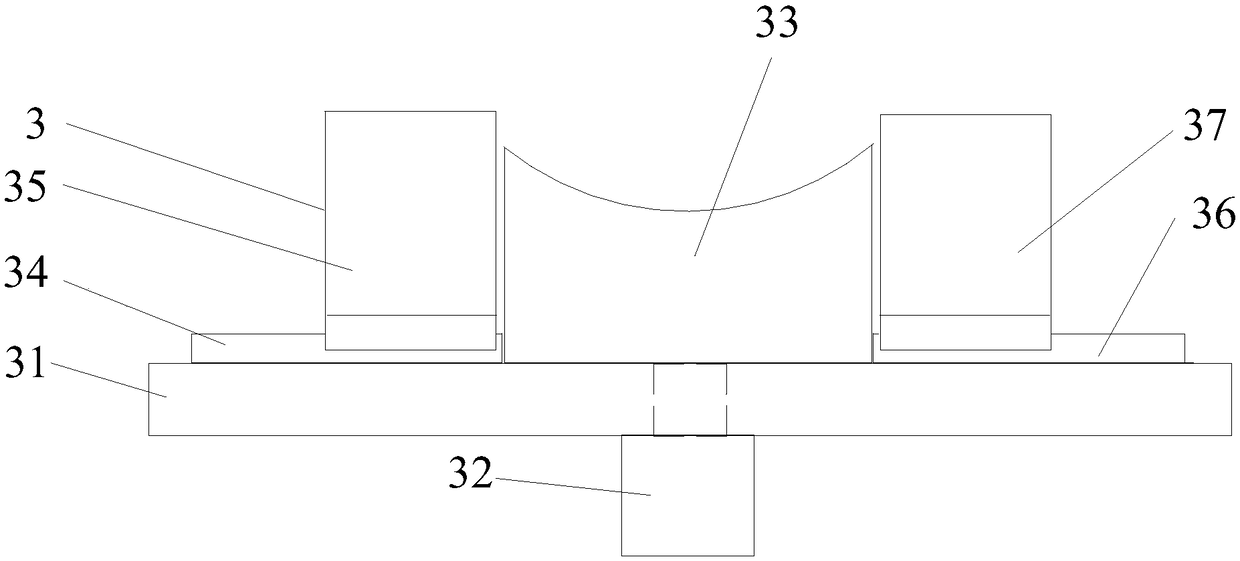

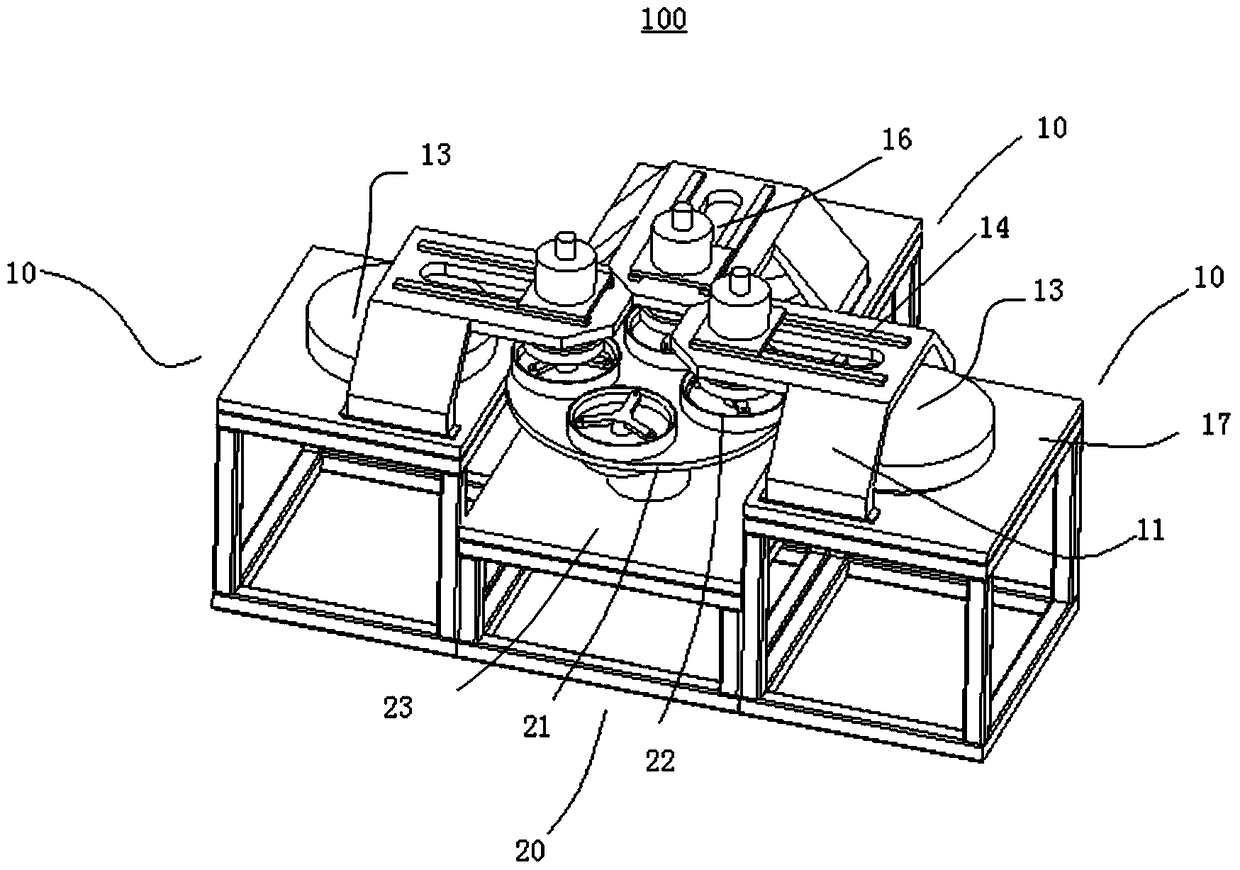

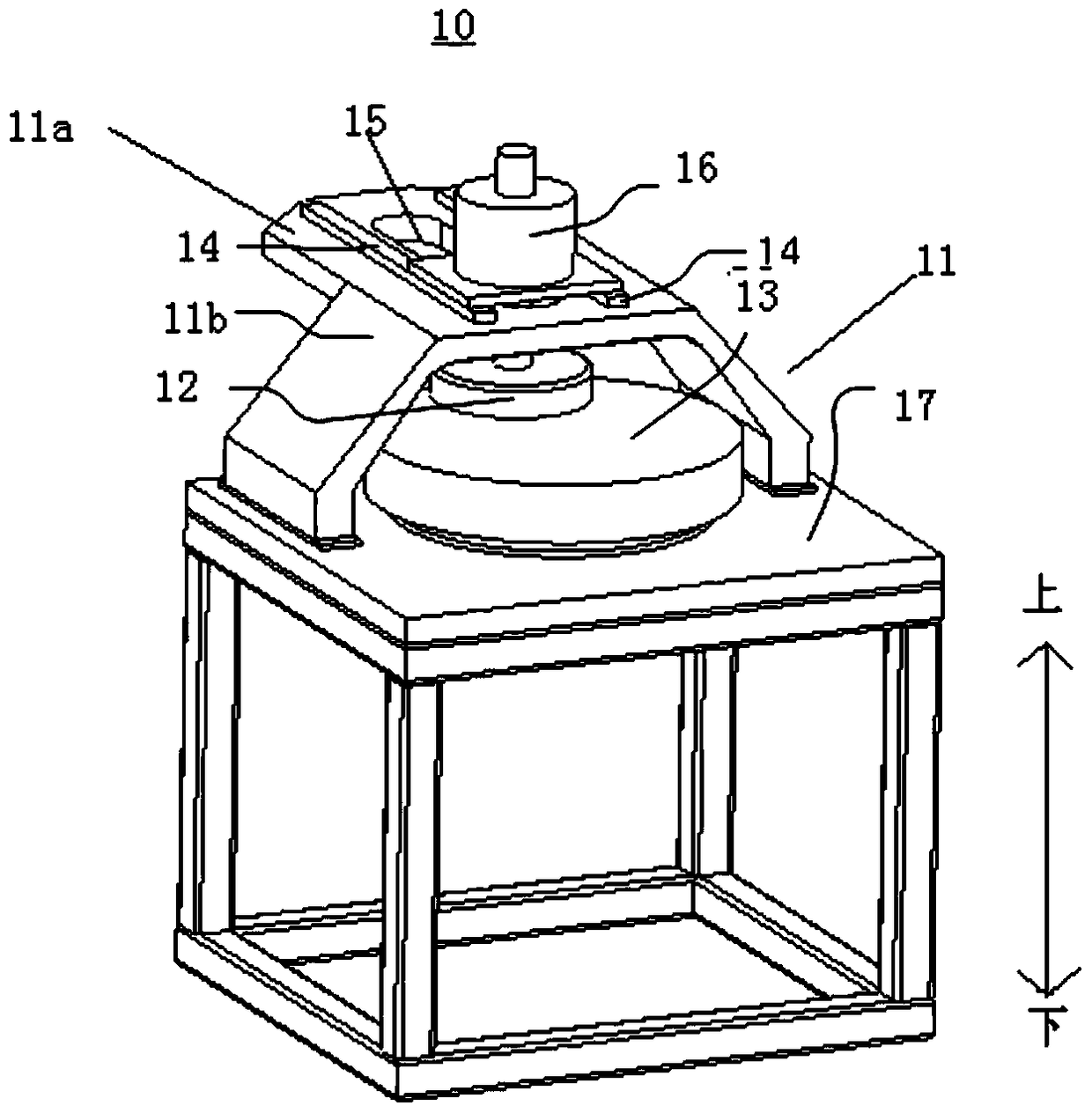

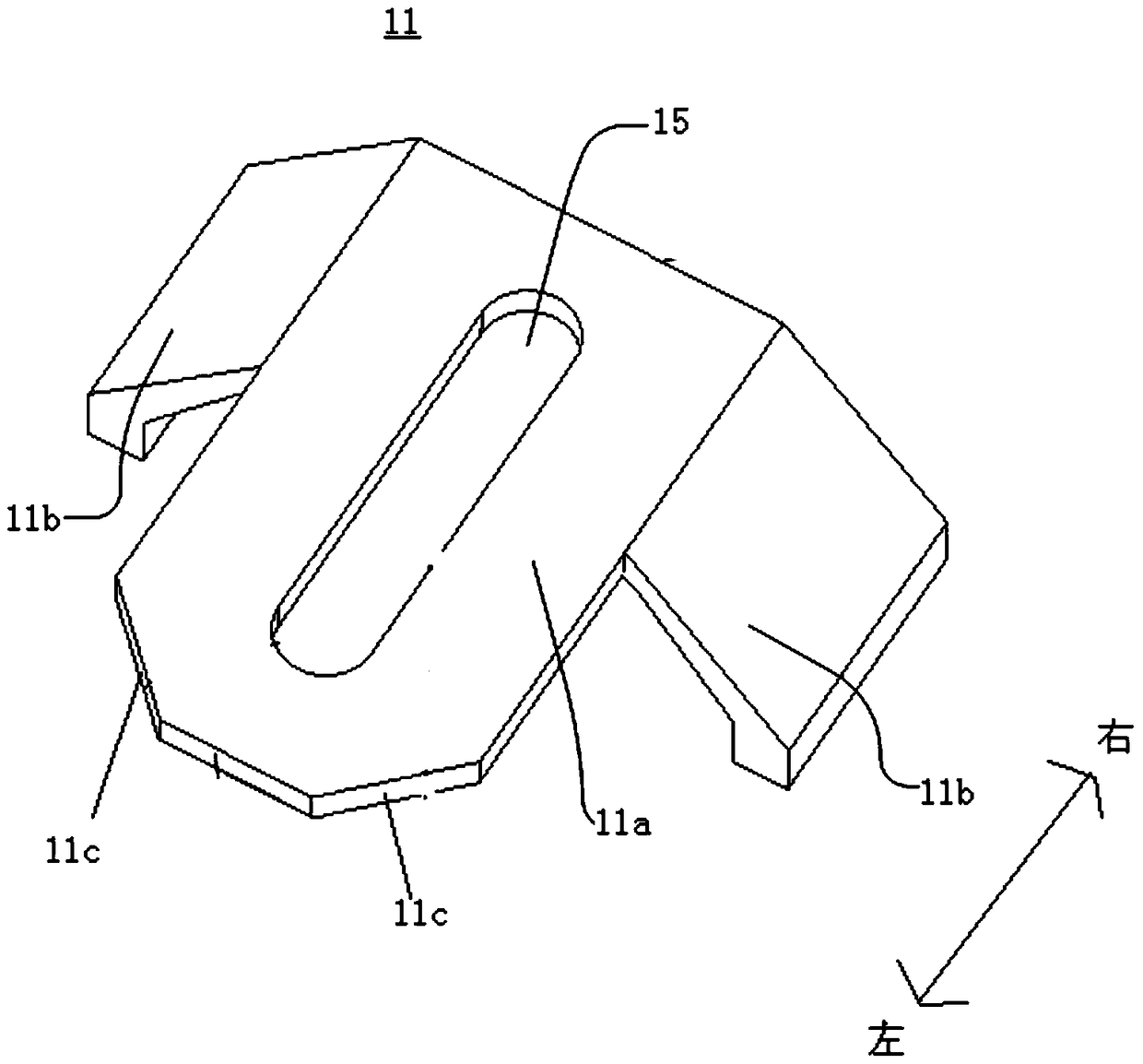

Prism magnetorheological polishing equipment

ActiveCN106736876BLow experience requirementLower skill requirementsOptical surface grinding machinesRotational axisPlastic materials

The invention discloses a prism magnetorheological polishing device comprising a rotating shaft, a work bench which is installed on the rotating shaft, multiple lifting jigs which are used for clamping prisms and a magnetorheological polisher which is used for polishing prism; the top surface of the work bench is provided with an annular groove for containing magnetorheological polishing solution, wherein the annular groove, the work bench and the rotating shaft are coaxially matched; the annular groove is made of plastic material; the multiple lifting jigs are uniformly installed inside the annular groove; the magnetorheological polisher comprises a rack, a polishing tool which is matched with the lifting jigs, a lifting device which is used for driving the polishing tool to go up and down and a main shaft which is connected with the rack; the polishing tool is connected with the main shaft through the lifting device; the polishing tool is positioned in the place matched with the annular groove; the rotating shaft drives the work bench to rotate and drives the lifting jigs successively pass through under the polishing tool. By means of the above structure, the polishing efficiency is high and the polishing device is suitable for industrialization production and application. The processing cost is low, and the experience or technical ability requirements are low for detecting and precision controlling operation personnel.

Owner:中山市光大光学仪器有限公司

A Polishing Method Combining Electrolytic Polishing and Chemical Mechanical Polishing for Aluminum Nitride Single Wafer

ActiveCN108381379BShorten polishing timeImprove processing efficiencySemiconductor/solid-state device manufacturingLapping machinesElectrolysisPhosphoric acid

The invention discloses an aluminum nitride single crystal wafer electrolytic polishing and chemical mechanical polishing combined polishing method. An electrolytic polishing solution is made of raw materials including 6 to 7% of sulfamic acid, 0.5 to 1% of oxalic acid, 0.5 to 1.5% of EDTA and 91.5 to 92% of deionized water. After electrolytic polishing is carried out, quartz wax is used for pasting an aluminum nitride single crystal wafer to a ceramic disc, a blade is used for scraping a small amount of wax flowing out of the edge of the wafer, and cleaning is achieved through alcohol; a chemical mechanical polishing solution is made of raw materials including, by weight percent, 16 to 20% of potassium dichromate, 2 to 6% of ammonium sulfate, 0.2 to 4% of nitric acid or sulfuric acid or phosphoric acid and 74 to 77% of deionized water. In the polishing process, an adopted polishing pad is a non-woven polishing cloth. After machining through the method, the wafer surface achieves global planarizartion, no scratch and uneven condition exists, the surface roughness Ra is smaller than or equal to 0.2 nm, and the whole net processing time can be shortened to be within one hour.

Owner:CHINA ELECTRONICS TECH GRP NO 46 RES INST

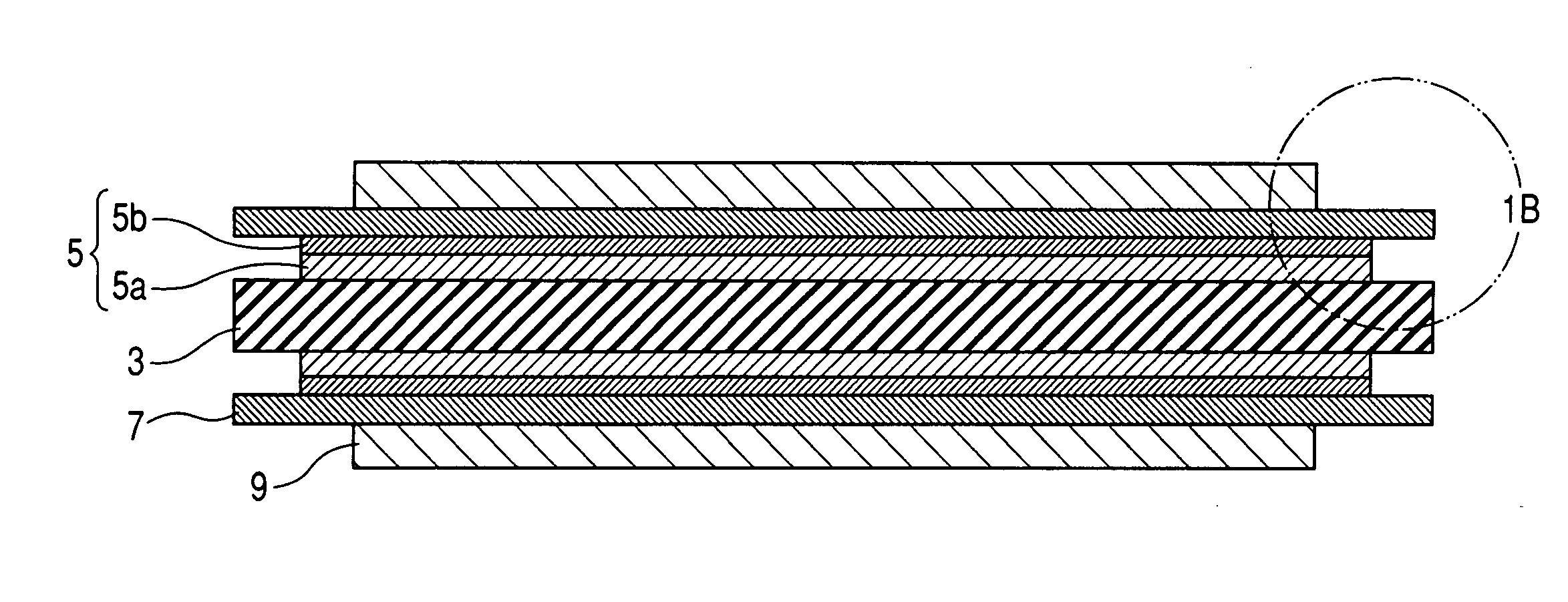

Method of manufacturing laminated substrate

InactiveUS7563342B2Good surface smoothnessReduce variationPrinted circuit aspectsLaminationEngineeringMechanical engineering

In a press process, a buffer member is placed on an RCC with a stainless steel plate between in such a way that the long sides and the short sides of the buffer member are aligned with the long sides and the short sides of the RCC respectively. The length of the long sides and the length of the short sides of the buffer member are designed to be smaller than the lengths of the long sides and the length of the short sides of the RCC respectively. With this feature, it is possible to reduce convexity on the RCC that is created in the peripheral region upon pressing the RCC to a core member.

Owner:TDK CORPARATION

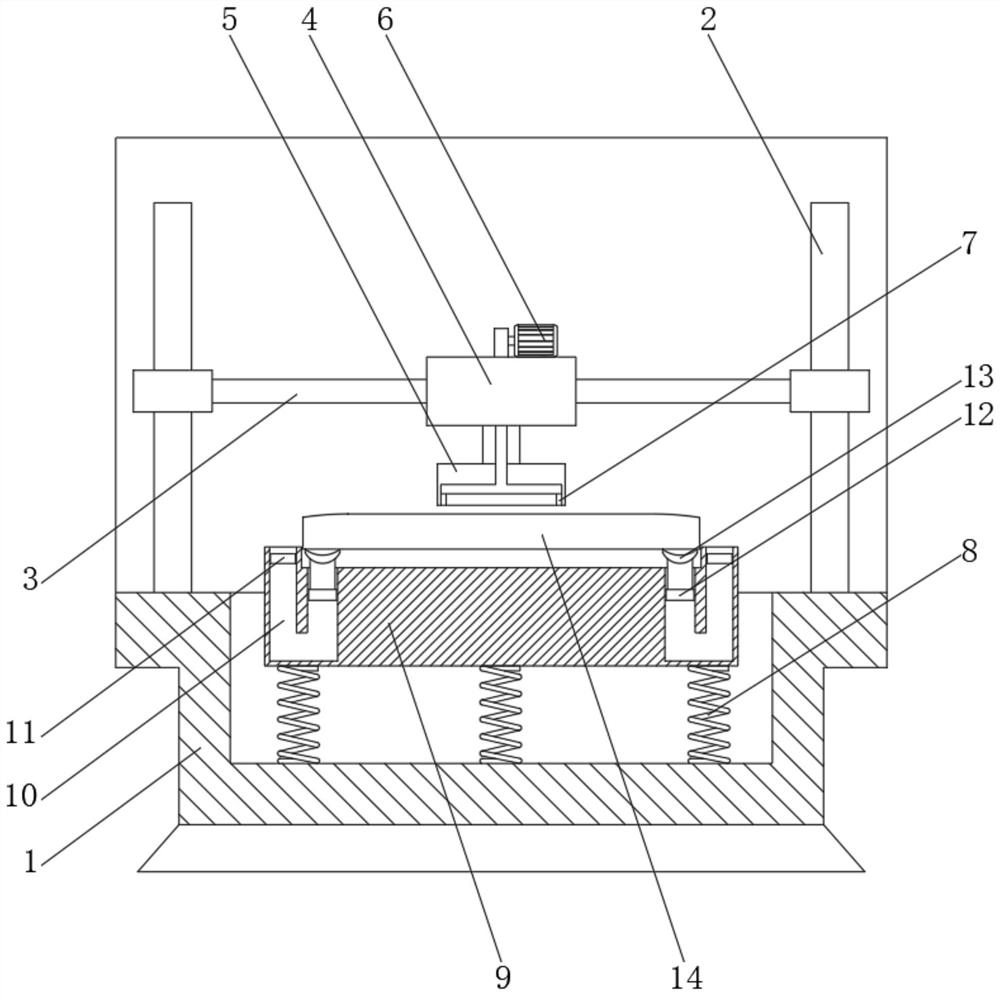

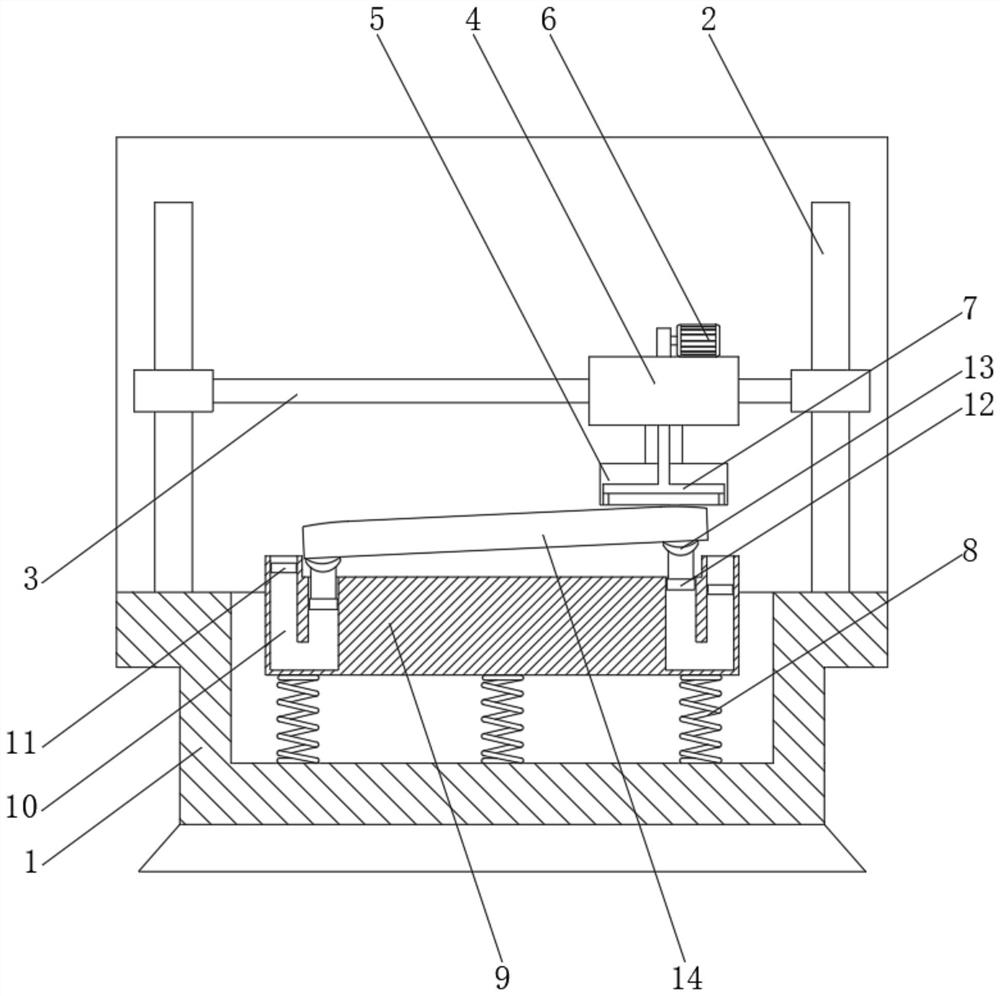

Rough-wrought workpiece polishing device for mold production

InactiveCN112405301ASimple polishing processImprove polishing efficiencyGrinding carriagesPolishing machinesPolishingAir pump

The invention relates to the technical field of production equipment, and discloses a rough-wrought workpiece polishing device for mold production. The rough-wrought workpiece polishing device comprises a device base, wherein the top end of the device base is fixedly connected with a lifting frame, the top end of the lifting frame is movably connected with a moving frame, the middle of the movingframe is movably connected with a moving block, the bottom end of the moving block is fixedly provided with a sand disc, the top end of the moving block is fixedly provided with an air pump, an air passage is formed in the sand disc, air blowing openings are formed in the two sides of the bottom end of the sand disc, and a buffer spring is fixedly arranged in the middle of the device base. According to the rough-wrought workpiece polishing device, the air blowing openings are formed in the two sides of the sand disc and are connected with the air pump through the air passage, so that the polishing device is used for continuously blowing air to the surface of the polishing surface by utilizing the air pump when polishing work is carried out, fine sand grains or other impurities on the surface of a polishing piece are cleaned, the cleaning work when the sand disc is replaced during each polishing is replaced, the polishing process is simplified, and the polishing efficiency is improved.

Owner:魏绣娟

chemical mechanical polisher

ActiveCN105598827BImprove processing stabilityIncrease productivityLapping machinesGrinding machinesEngineeringMechanical engineering

The invention discloses a chemical mechanical polishing machine. The chemical mechanical polishing machine comprises: a plurality of polishing components arranged at intervals and each of the polishing components comprises: a support, a polishing head and a polishing disc, and the polishing The head is arranged on the support and is adapted to move between a polishing position and a transmission position. When the polishing head is in the polishing position, the polishing head is located above the polishing disc; a transmission assembly, the transmission assembly includes : a turntable and a plurality of loading and unloading platforms, a plurality of loading and unloading platforms are arranged on the turntable at intervals and rotate with the turntable, when the polishing head is in the transmission position, the polishing head and the plurality of loading and unloading platforms corresponding to one of the platforms. Therefore, the mounting stability of the bracket is good, the working reliability of the polishing component is high, and the process stability of the polishing machine is good.

Owner:HWATSING TECH +1

Method of manufacturing laminated substrate

InactiveUS20060237131A1Good surface smoothnessReduce variationPrinted circuit aspectsLaminationEngineeringMechanical engineering

In a press process, a buffer member is placed on an RCC with a stainless steel plate between in such a way that the long sides and the short sides of the buffer member are aligned with the long sides and the short sides of the RCC respectively. The length of the long sides and the length of the short sides of the buffer member are designed to be smaller than the lengths of the long sides and the length of the short sides of the RCC respectively. With this feature, it is possible to reduce convexity on the RCC that is created in the peripheral region upon pressing the RCC to a core member.

Owner:TDK CORPARATION

Prism magnetorheological polishing device

ActiveCN106736876ALow experience requirementLower skill requirementsOptical surface grinding machinesPlastic materialsProcessing cost

The invention discloses a prism magnetorheological polishing device comprising a rotating shaft, a work bench which is installed on the rotating shaft, multiple lifting jigs which are used for clamping prisms and a magnetorheological polisher which is used for polishing prism; the top surface of the work bench is provided with an annular groove for containing magnetorheological polishing solution, wherein the annular groove, the work bench and the rotating shaft are coaxially matched; the annular groove is made of plastic material; the multiple lifting jigs are uniformly installed inside the annular groove; the magnetorheological polisher comprises a rack, a polishing tool which is matched with the lifting jigs, a lifting device which is used for driving the polishing tool to go up and down and a main shaft which is connected with the rack; the polishing tool is connected with the main shaft through the lifting device; the polishing tool is positioned in the place matched with the annular groove; the rotating shaft drives the work bench to rotate and drives the lifting jigs successively pass through under the polishing tool. By means of the above structure, the polishing efficiency is high and the polishing device is suitable for industrialization production and application. The processing cost is low, and the experience or technical ability requirements are low for detecting and precision controlling operation personnel.

Owner:中山市光大光学仪器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com