A Polishing Method Combining Electrolytic Polishing and Chemical Mechanical Polishing for Aluminum Nitride Single Wafer

An electrolytic polishing and chemical mechanical technology, applied in grinding/polishing equipment, circuits, grinding machine tools, etc., can solve the problems of few polishing methods, scratches on the wafer surface, poor wafer quality, etc., and achieve simple polishing process, The effect of less polishing damage and shorter polishing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

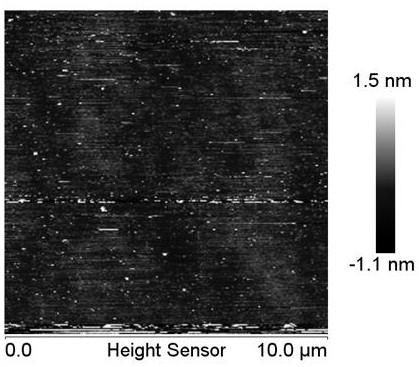

Image

Examples

Embodiment 1

[0026] The first step, electrolytic polishing;

[0027] For electropolishing, a 10mm×10mm aluminum nitride wafer was placed on the anode, lead was used as the cathode, and the electrolysis temperature was controlled at 20°C. Polishing fluid and related parameters are as follows:

[0028] Electropolishing fluid ratio: 6g sulfamic acid (NH 2 SO 3 H) + 1g oxalic acid (H 2 C 2 o 4 )+1.5gEDTA+91.5g deionized water.

[0029] Polishing parameters: pulsed DC power supply voltage 25V, working ratio 1:10, pulse frequency 1.6Hz, current density 5A / dm 2 , stirring speed 3r / s, polishing time 5min.

[0030] The second step, chemical mechanical polishing;

[0031] Clean the wafer obtained by electrolytic polishing, and paste it evenly on the ceramic plate for chemical mechanical polishing. The polishing liquid and related parameters are as follows:

[0032] Polishing liquid: 20g of potassium dichromate (Na 2 Cr 2 o 7 ), 2g ammonium sulfate ((NH 4 ) 2 SO 4 ) and 77g of deionize...

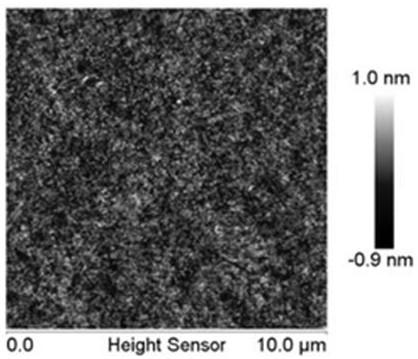

Embodiment 2

[0036]The first step, electrolytic polishing;

[0037] For electropolishing, a 10mm×10mm aluminum nitride wafer was placed on the anode, lead was used as the cathode, and the electrolysis temperature was controlled at 20°C. Polishing fluid and related parameters are as follows:

[0038] Electropolishing fluid ratio: 7g sulfamic acid (NH 2 SO 3 H)+0.5g oxalic acid (H 2 C 2 o 4 )+0.5gEDTA+92g deionized water.

[0039] Polishing parameters: pulsed DC power supply voltage 45V, working ratio 1:4, pulse frequency 3.0Hz, current density 15A / dm 2 , stirring speed 3r / s, polishing time 5min.

[0040] The first step, chemical mechanical polishing;

[0041] Clean the wafer obtained by electrolytic polishing, and paste it evenly on the ceramic plate for chemical mechanical polishing. The polishing liquid and related parameters are as follows:

[0042] Polishing liquid: 16g of potassium dichromate (Na 2 Cr 2 o 7 ), 6g ammonium sulfate ((NH 4 ) 2 SO 4 ) and 74g of deionized wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com