Magneto-rheological amorphous alloy polishing device, polishing agent and polishing method

A technology of magnetorheological polishing and amorphous alloys, which is applied in the direction of grinding/polishing equipment, machine tools for surface polishing, and polishing compositions containing abrasives, etc. Achieve the effects of high process efficiency, green environmental protection and pollution-free process efficiency, and simple and easy-to-operate polishing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

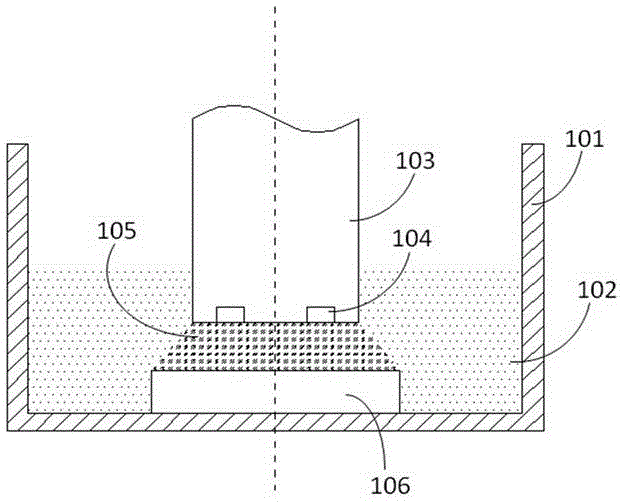

[0031] The magnetorheological polishing process in the prior art is as attached figure 1 As shown, its principle is: the workpiece 106 is placed in the polishing tank 101, the polishing tank is loaded with the polishing liquid 102, the magnetorheological liquid is ejected through the nozzle hole 104 on the polishing head 103, and under the action of the magnetic polishing head 103, the spray The magneto-rheological liquid produced has a magneto-rheological effect, that is, the magnetic particles of the magneto-rheological liquid form a magnetic chain bundle along the direction of the magnetic force lines of the magnetic field, and at the same time, the polishing powder particles in the magnetorheological polishing liquid are also wrapped in it, during polishing A viscoplastic flexible aggregate 105 containing polishing powder with a certain hardness a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com