Low-cost porous titanium alloy metallographic polishing reagent and polishing process

A titanium alloy, low-cost technology, applied in the field of low-cost porous titanium alloy metallographic polishing reagents and polishing technology, can solve the problems of high cost, poor metallographic polishing effect of titanium alloy, etc., achieve low cost, avoid deformation twinning, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1 of the present invention provides a low-cost porous titanium alloy metallographic polishing reagent, including a reagent composed of zirconia powder, yttrium oxide powder or a mixture of zirconia powder and yttrium oxide powder in any mass ratio mixed with water In this reagent, the mass ratio of zirconia powder, yttrium oxide powder or a mixture of zirconia powder and yttrium oxide powder to water is 2:10.

[0022] Further, the particle size of the zirconia powder or the yttrium oxide powder is not greater than 1 micron.

Embodiment 2

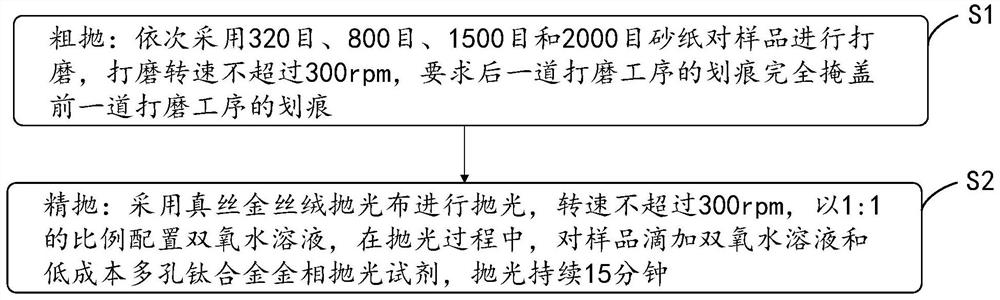

[0024] Such as figure 1 As shown, the second embodiment of the present invention provides a low-cost porous titanium alloy metallographic polishing process, comprising the following steps:

[0025] Taking TC4 as a sample, it was metallographically polished.

[0026] Step S1, rough polishing: use 320-mesh, 800-mesh, 1500-mesh and 2000-mesh sandpaper to polish the sample in sequence, and the grinding speed should not exceed 300rpm. It is required that the scratches of the latter grinding process completely cover the scratches of the previous grinding process;

[0027] Step S2, fine polishing: use silk velvet polishing cloth for polishing, the rotation speed does not exceed 300rpm, configure hydrogen peroxide solution at a ratio of 1:1, during the polishing process, add hydrogen peroxide solution and low-cost porous titanium alloy metallographic polishing to the sample Reagent, polish lasts 15 minutes.

[0028] Further, in the step of rough polishing, the duration of polishing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com