A kind of preparation method of zirconia molybdenum alloy electrode

A technology of molybdenum alloy and zirconia, which is applied in the field of preparation of zirconia-molybdenum alloy electrodes, can solve the problems that molybdenum electrodes are prone to embrittlement and fracture, the recrystallization temperature of pure molybdenum electrodes is low, and affect the normal development of industrial production. The preparation method is easy to control, the glass erosion resistance is good, and the operation is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

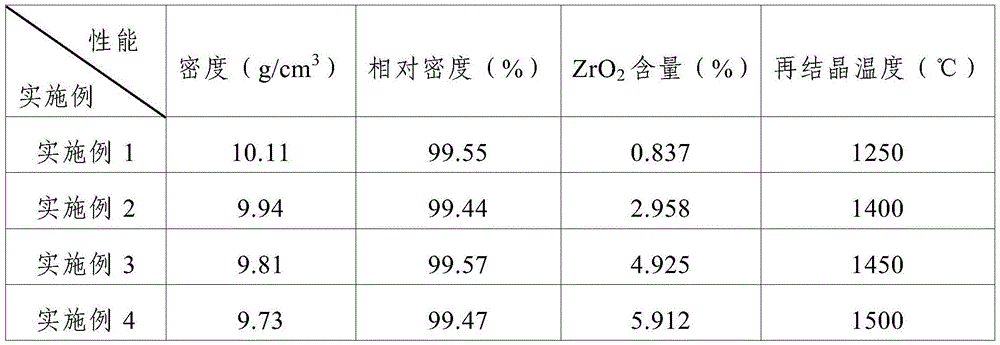

Examples

Embodiment 1

[0026] This embodiment includes the following steps:

[0027] Step 1, with 30kg molybdenum powder and 255g analytical pure ZrO 2 The powder is placed in a V-type mixer and mixed evenly to obtain Mo-ZrO 2 Alloy powder; the average Fischer particle size of the molybdenum powder is 1.5 μm, and the bulk density is 0.90 g / cm 3 ;

[0028] Step 2, the Mo-ZrO described in the step 1 is prepared by cold isostatic pressing 2 Alloy powder pressed into Mo-ZrO 2 Alloy rod; the pressing pressure is 180MPa, and the holding time is 8min;

[0029] Step 3, Mo-ZrO described in step 2 2 The alloy rod is placed in a medium-frequency induction sintering furnace, kept and sintered at 1980°C for 6 hours, and cooled with the furnace to obtain Φ110mm and a density of 9.75g / cm 3 Mo-ZrO 2 Sintered alloy rod;

[0030] Step 4, Mo-ZrO described in step 3 2 The sintered alloy rod was placed in a muffle furnace, heated to 1450 °C under the protection of hydrogen, and then kept for 90 minutes. The Mo-...

Embodiment 2

[0035] This embodiment includes the following steps:

[0036] Step 1, 30kg molybdenum powder and 900g analytical pure ZrO 2 The powder is placed in a V-type mixer and mixed evenly to obtain Mo-ZrO 2 Alloy powder; the average Fischer particle size of the molybdenum powder is 2.85 μm, and the bulk density is 1.08 g / cm 3 ;

[0037] Step 2, the Mo-ZrO described in the step 1 is prepared by cold isostatic pressing 2 Alloy powder pressed into Mo-ZrO 2 Alloy rod; the pressing pressure is 200MPa, and the holding time is 10min;

[0038] Step 3, Mo-ZrO described in step 2 2 The alloy rod is placed in a medium-frequency induction sintering furnace, kept and sintered at 2000°C for 7 hours, and cooled with the furnace to obtain Φ200mm and a density of 9.45g / cm 3 Mo-ZrO 2 Sintered alloy rod;

[0039] Step 4, Mo-ZrO described in step 3 2 The sintered alloy rod was placed in a muffle furnace, heated to 1470 °C under the protection of argon, and then kept for 90 minutes. The Mo-ZrO 2...

Embodiment 3

[0044] This embodiment includes the following steps:

[0045] Step 1, 30kg molybdenum powder and 1500g analytical pure ZrO 2 The powder is placed in a V-type mixer and mixed evenly to obtain Mo-ZrO 2 Alloy powder; the average Fischer particle size of the molybdenum powder is 3.32 μm, and the bulk density is 1.16 g / cm 3 ;

[0046] Step 2, the Mo-ZrO described in the step 1 is prepared by cold isostatic pressing 2 Alloy powder pressed into Mo-ZrO 2 Alloy rod; the pressing pressure is 190MPa, and the holding time is 10min;

[0047] Step 3, Mo-ZrO described in step 2 2 The alloy rod is placed in a medium-frequency induction sintering furnace, kept and sintered at 2100°C for 8 hours, and cooled with the furnace to obtain Φ48mm and a density of 9.33g / cm 3 Mo-ZrO 2 Sintered alloy rod;

[0048] Step 4, Mo-ZrO described in step 3 2 The sintered alloy rod was placed in a muffle furnace, heated to 1480 °C under the protection of hydrogen, and then kept for 60 minutes. The Mo-ZrO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

| recrystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com