Non-wax polishing adsorption pad and manufacturing method thereof

A technology of adsorption pad and production method, applied in the direction of grinding tools, etc., can solve the problems of easy dislocation, low production qualification rate, product scrapping, etc., and achieve the effect of improving product qualification rate and simplifying polishing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be described in further detail below through specific examples, but it is not intended to limit the protection scope of the present invention.

[0060] Implementation column 1

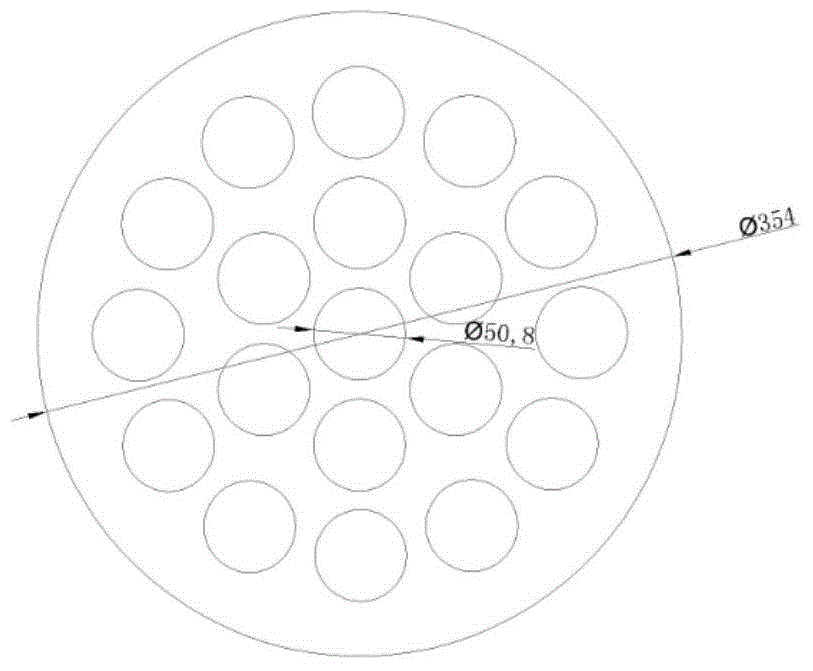

[0061] A wax-free polishing pad for 0.2mm optical lenses. It is a disc structure with a diameter of 354mm and 19 round holes, the hole diameter is 50.8mm, and the thickness of the surface grinding layer is 0.2mm. see details figure 1 .

[0062]The grinding plate is made of epoxy resin glass fiber plate with a thickness of 0.2mm. Adhesive layer 1 and adhesive layer 2 are both made of tpu hot-melt adhesive film with a melting point of 120°C and a thickness of 0.03mm (excluding release paper). The adsorption skin adopts damping cloth with a porosity of 60%, a thickness of 0.4mm, a void diameter of 5μm, and a density of 0.4g / cm 3 . The support layer is made of epoxy resin fiberglass board with a thickness of 0.2mm. The adhesive layer is made of non-woven pressure-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com