Metal polishing method

A metal and polishing liquid technology, applied in the field of mechanical processing, can solve the problems of time-consuming polishing and complicated polishing process, and achieve the effect of high polishing efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

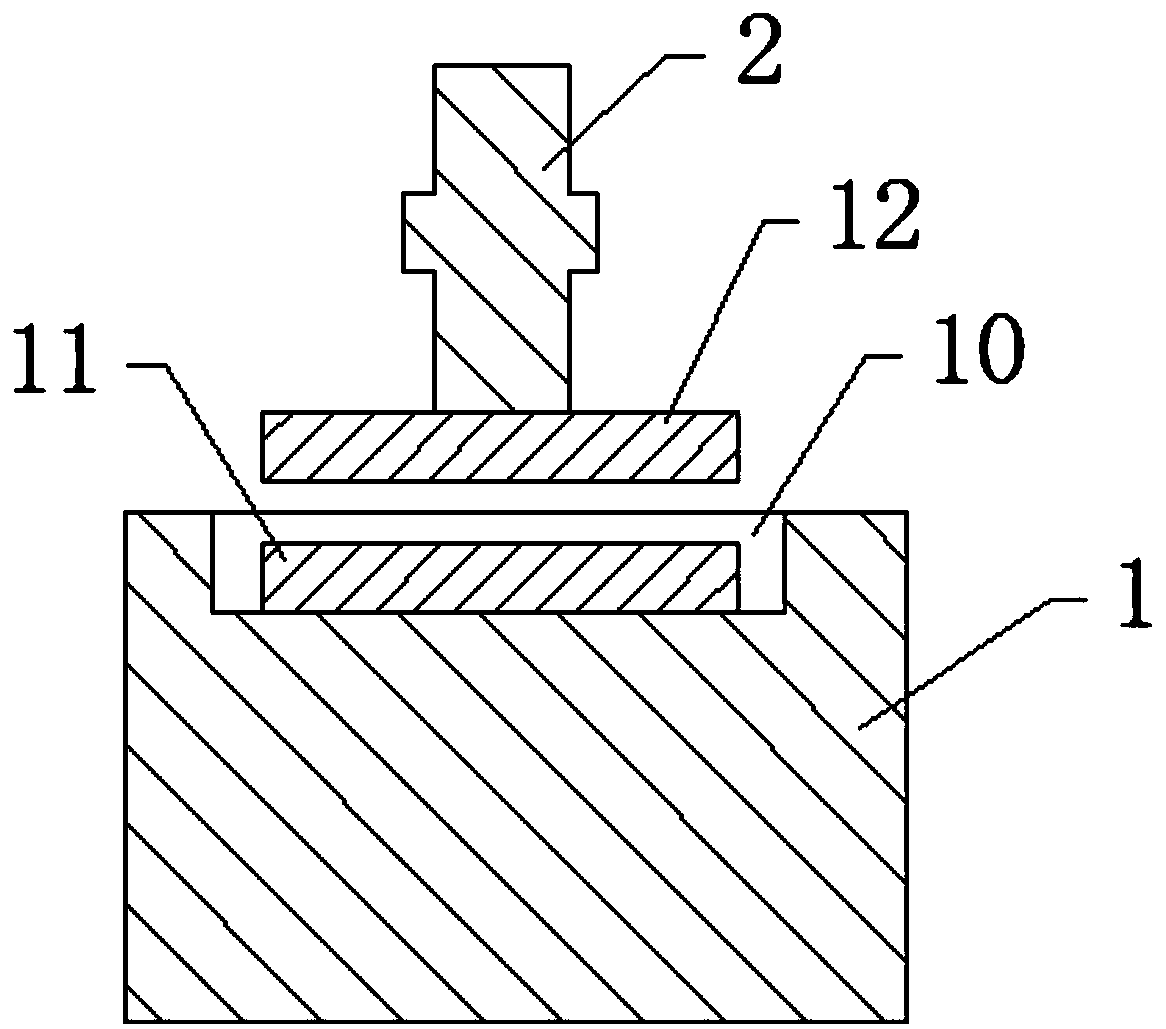

[0013] refer to figure 1 is an embodiment of the invention:

[0014] A metal polishing method, comprising the following steps: S1, annealing a cold-rolled coil profile to obtain an annealed profile; S2, sending the annealed profile into a first grinding machine, using a first polishing liquid on the first grinding machine to anneal the annealed profile; The profile is subjected to preliminary chemical mechanical polishing to obtain a polished profile; S3, the polished profile is sent to the cleaning pool for cleaning, and the product raw material is obtained; S4, the product raw material is sent to the punching machine for blanking, and the initial product is obtained; S5, the initial product is prepared. The product is sent to the first grinding machine, and the second polishing solution is used on the first grinding machine to perform secondary chemical mechanical polishing on the initial product to obtain the product.

[0015] The surface quality of the cold-rolled coil pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com