Copper tile roof lightning strip structure and construction method thereof

A construction method and technology of lightning protection belt, applied in the direction of roof, roof covering, building roof, etc., can solve the problems of copper tile surface flatness exceeding the standard allowable deviation, destroying the design effect, etc., to achieve good lightning protection effect and harmonious roof decoration style. , The effect of simple construction method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

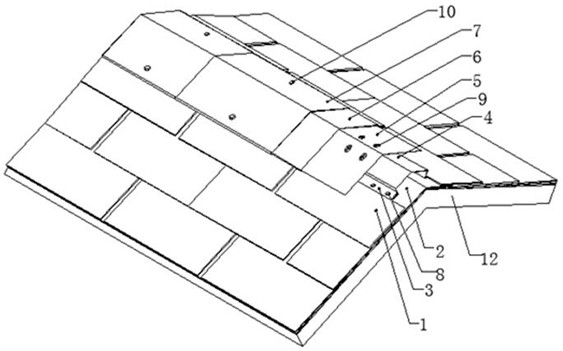

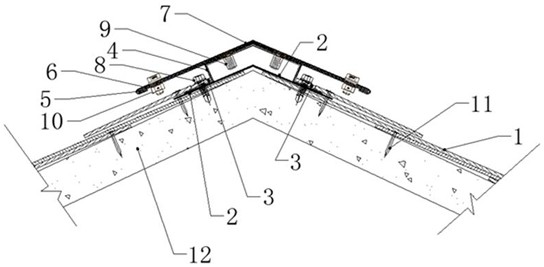

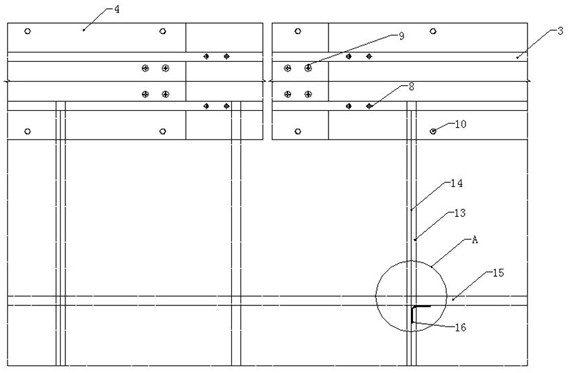

[0035] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the said scope.

[0036] Such as Figure 1-5 As shown, a copper tile roof lightning protection belt structure, the copper tile roof is provided with a roof copper tile 1, and the roof ridge of the roof copper tile 1 is laid with a waterproof membrane reinforcement layer 2 for waterproofing, and the waterproof membrane reinforcement layer 2 is laid There is a first male ridge lining 4, and hot-dip galvanized flat steel 3 for lightning protection is provided on both sides of the first male ridge lining 4, wherein the hot-dip galvanized flat steel 3 is reliably electrically connected to the lightning protection down conductor, and the second Both sides of a male ridge liner 4 are respectively provided with a first connection hole, and the hot-dip galvanized flat steel 3 is provided with a second connection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com