Plastic pipe injection molding cooling device

A cooling device and plastic tube technology, which is applied to tubular items, other household appliances, household appliances, etc., can solve the problems of shrinking and slowing down the inner diameter of the plastic tube injection cooling box.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

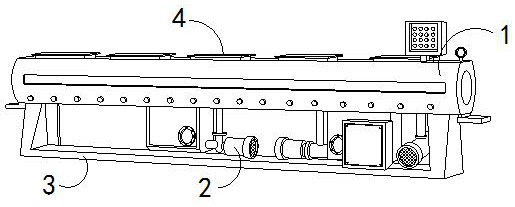

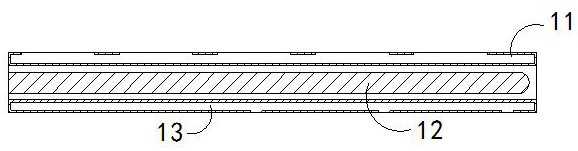

[0027] For example figure 1 -example Figure 5 Shown:

[0028] The invention provides a cooling device for injection molding of plastic pipes, the structure of which includes a cooling box 1, a heat dissipation fan 2, a base 3, and a ventilation chamber 4. The heat dissipation fan 2 is fixed at the bottom of the cooling box 1, and the bottom of the ventilation chamber 4 Embedded in the upper position of the cooling box 1, the bottom position of the cooling box 1 is welded to the top of the base 3; the cooling box 1 includes an upper cavity 11, a molding rod 12, and a lower cavity 13. The placement chamber 11 and the lower placement chamber 13 are an integral structure, and the molding rod 12 runs through between the upper placement chamber 11 and the lower placement chamber 13 .

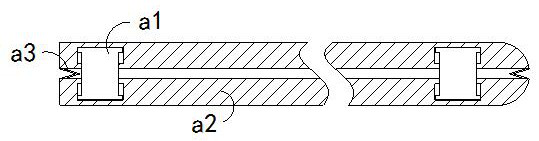

[0029] Wherein, the molding rod 12 includes a linkage block a1, an outer expansion plate a2, and a booster piece a3. Between the inner sides of the expansion board a2, there are two outer expansio...

Embodiment 2

[0035] For example Figure 6 -example Figure 9 Shown:

[0036]Wherein, the upper swing plate b4 includes a force plate b41, an impact block b42, and a bottoming block b43, the force plate b41 is embedded in the inner position of the bottom block b43, and the impact block b42 is installed on the force plate b41 The internal position of the impact block b42 is made of high-density alloy steel. Through the swinging force generated by the mechanism, the impact block b42 can repeatedly impact the upper end of the inner wall of the force plate b41, so that the adhesion on the bottoming can be eliminated. The polyvinyl chloride plastic on the upper surface of block b43 vibrates until it becomes loose.

[0037] Wherein, the stressed plate b41 includes an upper extension rod c1, a lower frame c2, and a board surface c3. The bottom of the upper extension rod c1 is provided with five, and evenly distributed in parallel inside the board surface c3, the vibration received by the mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com