Method for controlling reaction temperature of powdered coal gasification furnace by using thermal load

A technology of reaction temperature and gasification furnace, which is applied in the field of controlling the reaction temperature of pulverized coal gasification furnace, and can solve the problems of not being able to judge the furnace temperature of the gasification furnace accurately and in a timely manner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0024] Example 1:

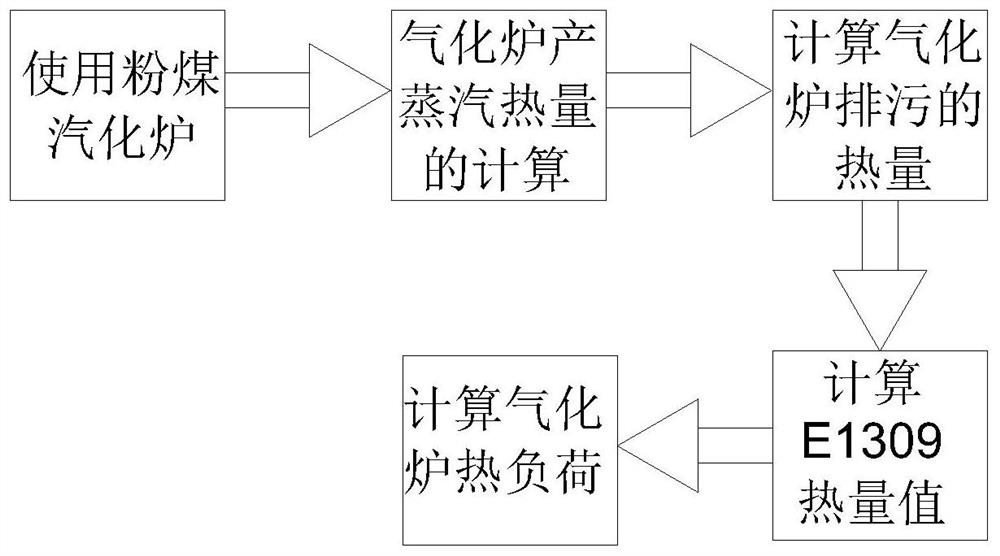

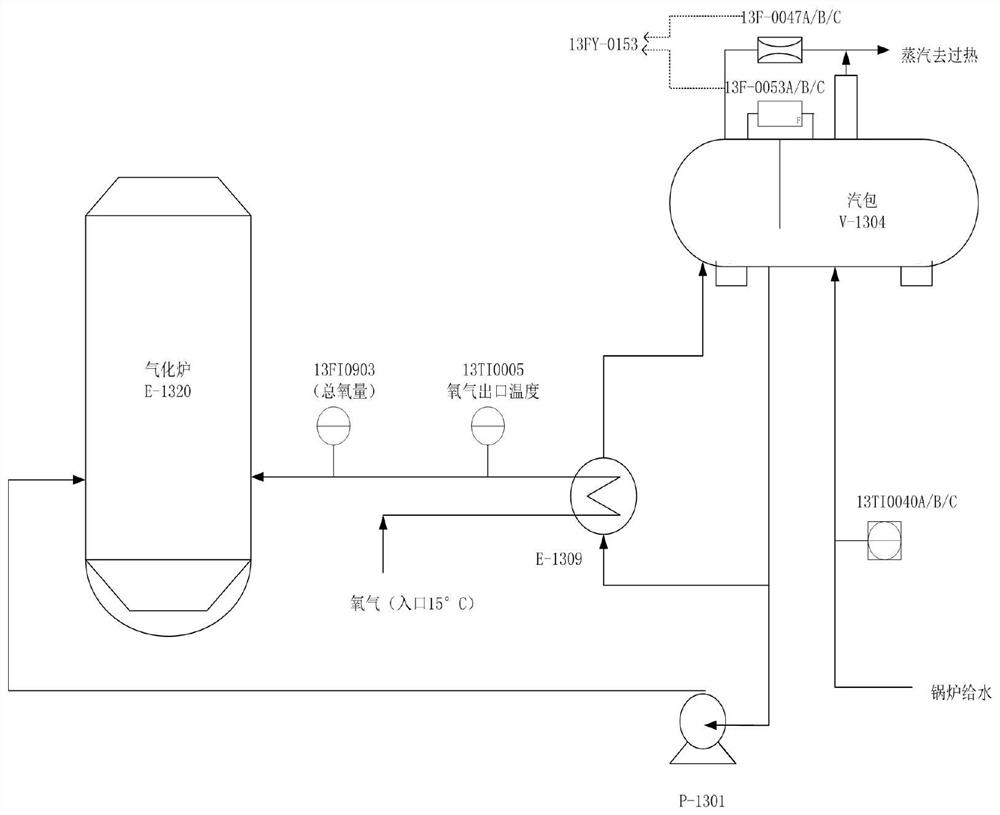

[0025] according to Figure 1-3 As shown, a method of thermal load is used to control the temperature of the powder gasifier, the method comprising the steps of:

[0026] S1, using a powder vaporization furnace, heat the pulverized coal steaming furnace, until the fixed slag layer and the flow slag layer thickness on the water-cooled wall are dynamic equilibrium;

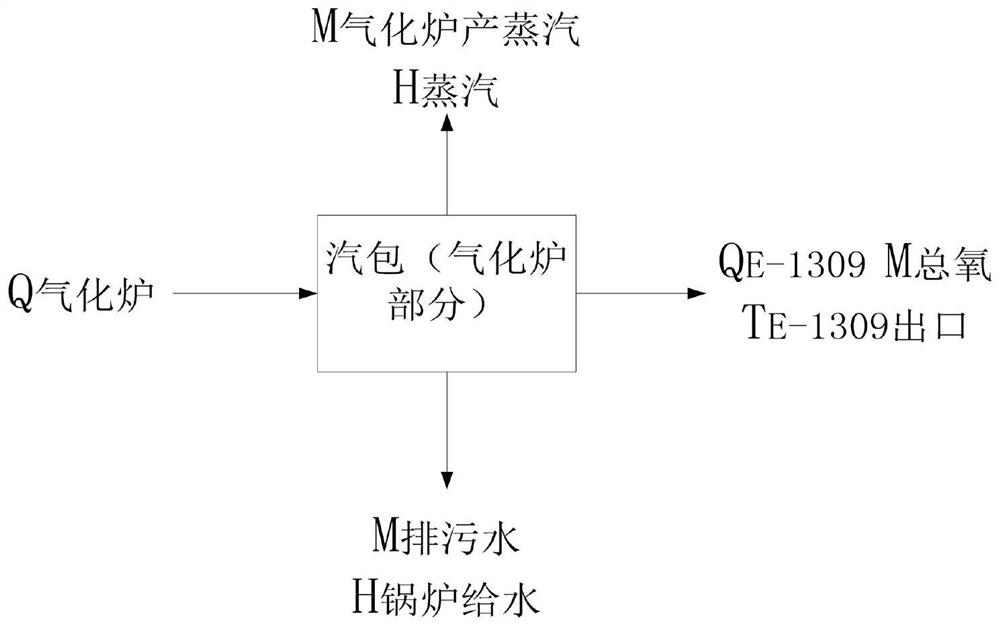

[0027] S2, the calculation of gasification furnace production, using corresponding instruments to measure the mass flow of gasification furnace vapor and gasification furnace water temperature, then subjected to the measured data into formula 1, to obtain gasification furnace steam heat value:

[0028] S3, calculate the heat of the gasifier sewage, use the corresponding instrument to measure the mass flow and temperature of the sewage of the vaporization furnace, and calculate the heat of the emission furnace sewage;

[0029] S4, calculate the E1309 calorie value, using the corresponding instrument to...

Example Embodiment

[0038] Example 2:

[0039] according to Figure 1-3 As shown, a method of thermal load is used to control the temperature of the powder gasifier, the method comprising the steps of:

[0040] S1, using a powder vaporization furnace, heat the pulverized coal steaming furnace, until the fixed slag layer and the flow slag layer thickness on the water-cooled wall are dynamic equilibrium;

[0041] S2, the calculation of gasification furnace production, using corresponding instruments to measure the mass flow of gasification furnace vapor and gasification furnace water temperature, then subjected to the measured data into formula 1, to obtain gasification furnace steam heat value:

[0042] S3, calculate the heat of the gasifier sewage, use the corresponding instrument to measure the mass flow and temperature of the sewage of the vaporization furnace, and calculate the heat of the emission furnace sewage;

[0043] S4, calculate the E1309 calorie value, using the corresponding instrument to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com