Spectroscopic prism fixing component and projection light machine

A technology of beam splitting prism and fixed components, applied in optics, instruments, projection devices, etc., can solve the problem of no compact beam splitting prism, and achieve the effect of compact structure, small occupied space and high practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

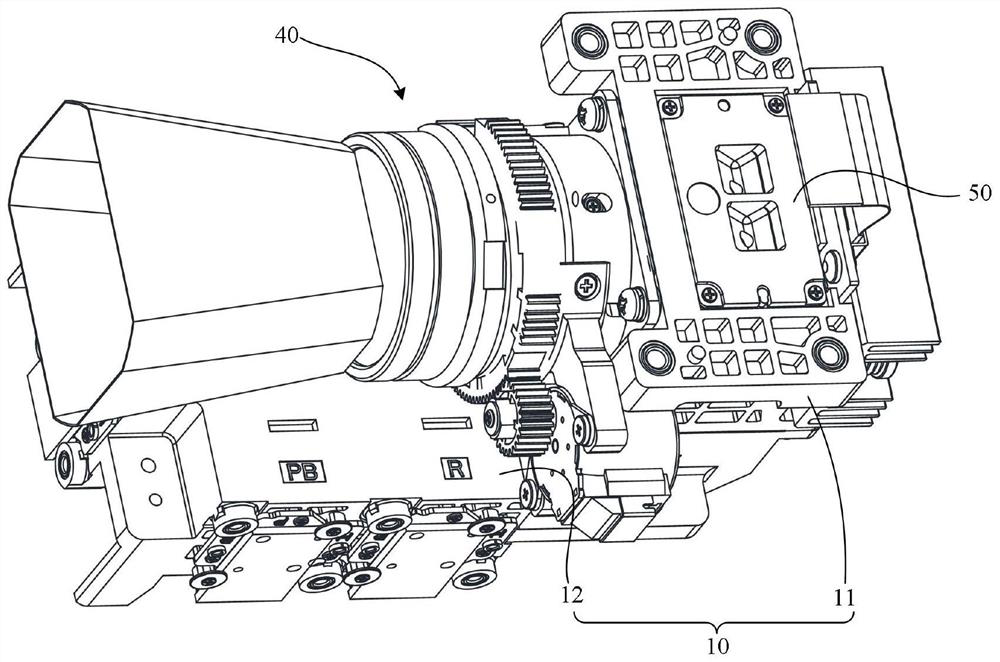

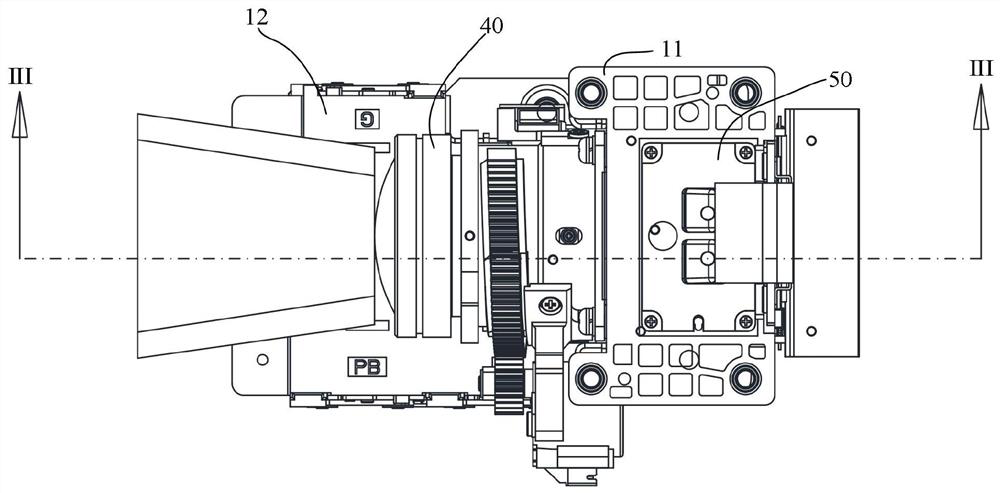

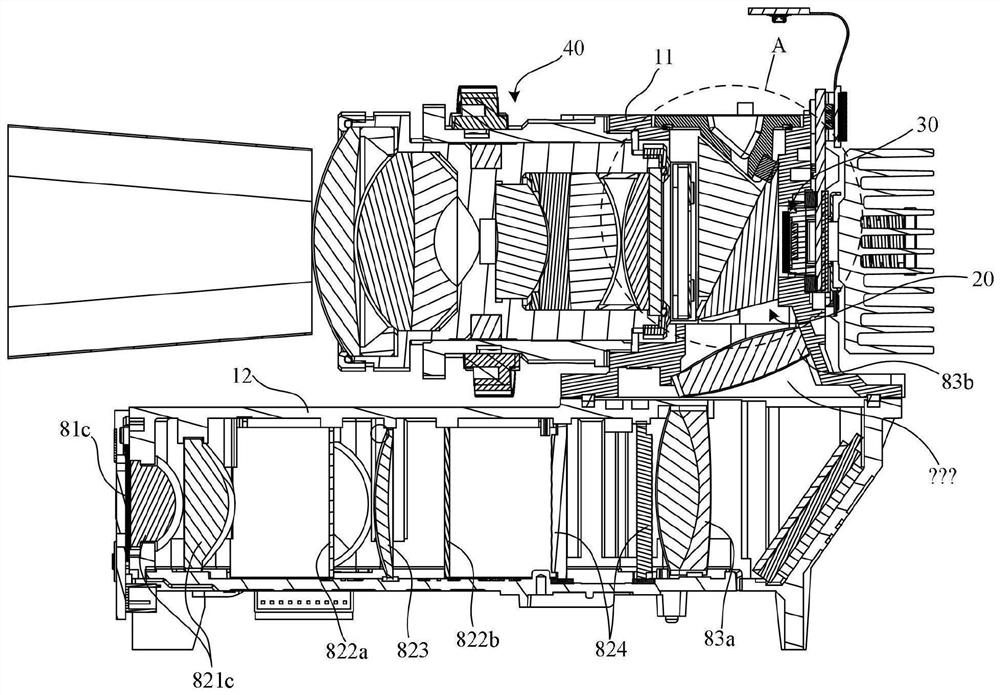

[0053] In order to better illustrate the technical solution and beneficial effect of the beam splitting prism fixing assembly of the present invention, the projection light machine of a preferred embodiment of the invention will be introduced together with the introduction of the beam splitting prism fixing assembly of the present invention.

[0054] Please refer to Figure 1-6 , Figure 11 to Figure 14 as well as Figure 18 , in one embodiment, the light projection machine of the present invention includes a DMD light modulator 30, a projection lens 40 and a beam splitting prism fixing assembly, the DMD light modulator 30 is installed in the rear installation port 111b of the housing 10, and the projection lens 40 is installed in The front mounting opening 111a of the housing 10.

[0055] The dichroic prism fixing assembly includes a housing 10, a dichroic prism 20, an upper cover 50, a first elastic member 61, a second elastic member 62 and two third elastic members 63. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com