Relay contact mounting mechanism

A relay contact and installation mechanism technology, which is applied in the direction of relays, electromagnetic relays, electromagnetic relay details, etc., can solve the problems of discontinuity and pause in the feeding process, inconvenient clamping and installation mechanisms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

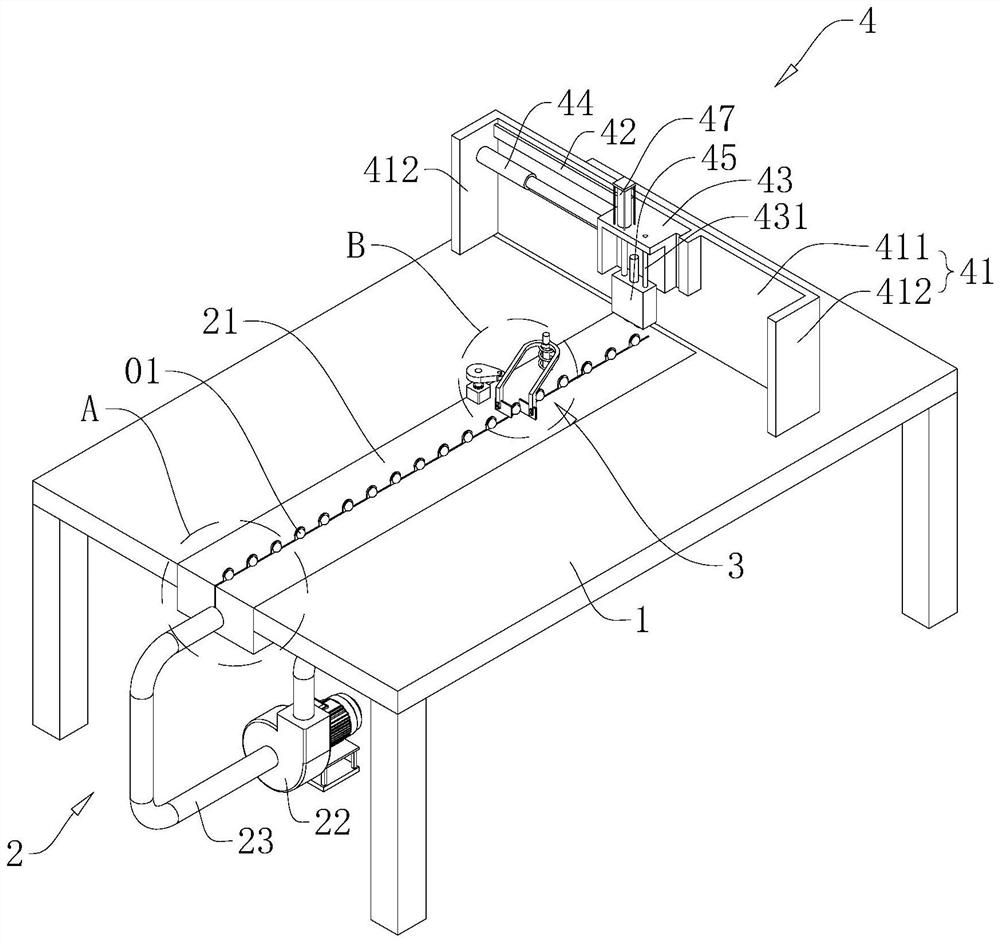

[0041] The following is attached Figure 1-7 The application is described in further detail.

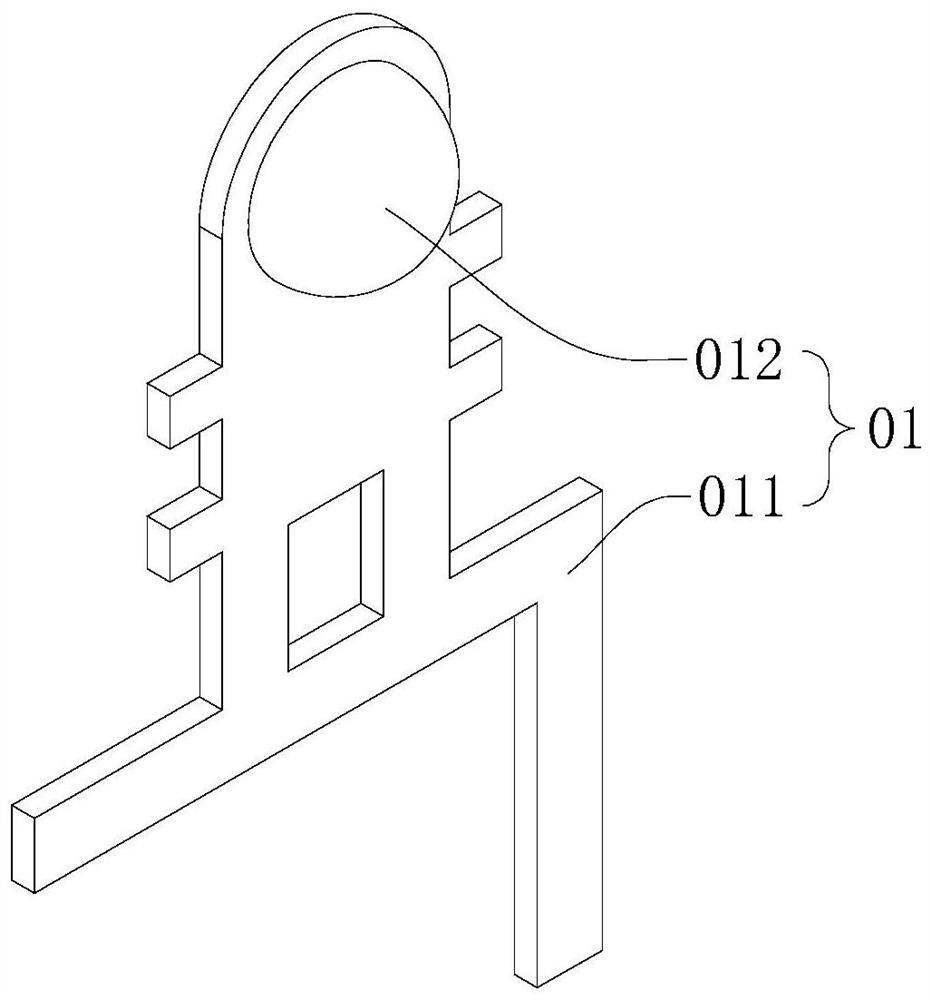

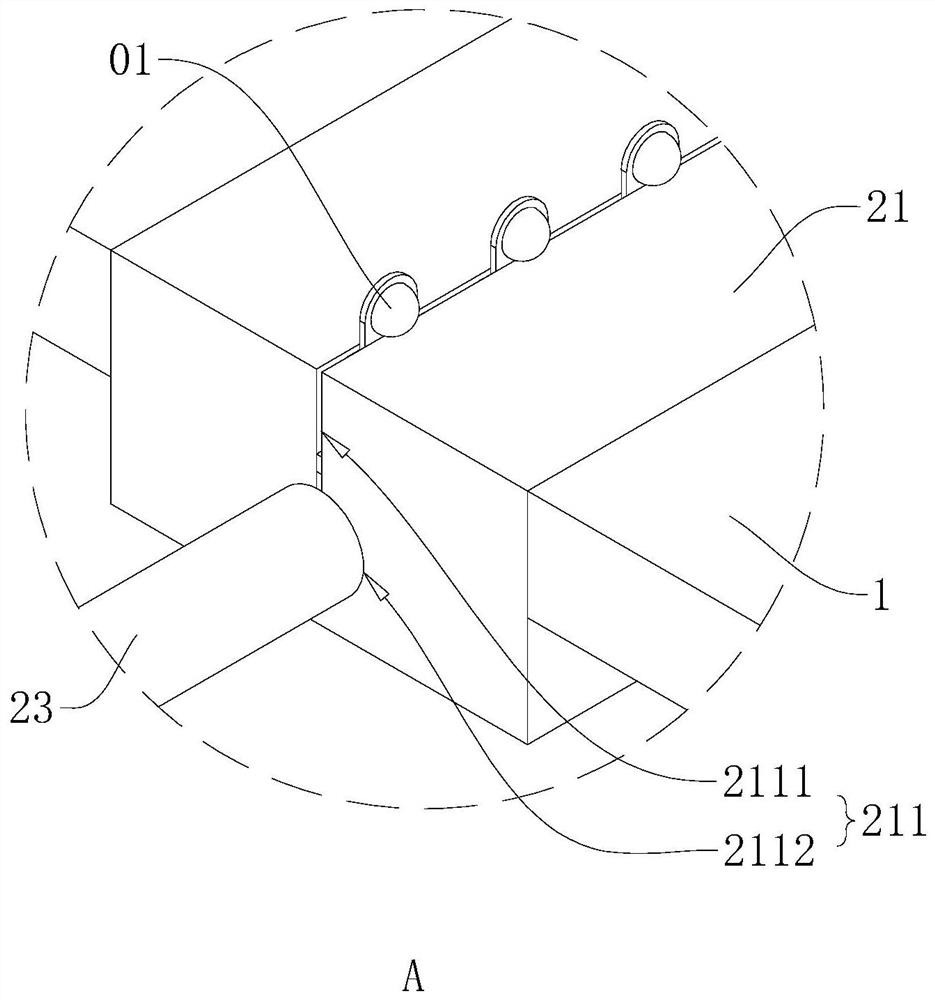

[0042] The embodiment of the present application discloses a relay contact installation mechanism. refer to figure 2 and image 3 , the relay contact installation mechanism includes a frame 1, a conveying device 2, a partition device 3 and a shifting device 4, wherein the conveying device 2 includes a slideway 21, and the slideway 21 is an elongated block structure with a rectangular cross section, and the slideway The channel 21 is horizontally fixed on the frame 1; the slideway 21 is provided with a delivery trough 211, the delivery trough 211 includes a support channel 2111 and an air channel 2112, and the support channel 2111 and the air channel 2112 communicate with each other, and the support channel 2111 is a strip-shaped slit And extend along the length direction of the slideway 21, the air channel 2112 is a channel with a circular cross section and also extends along the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com