Reciprocating rotating thermocouple

A technology of reciprocating rotation and thermocouples, which is applied in the direction of measuring heat, using electric devices, and thermometers using electric/magnetic elements that are directly sensitive to heat, can solve the problem of reducing the service life of thermocouples, inaccurate temperature detection of thermocouples, and a large number of Dust and other problems to achieve the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

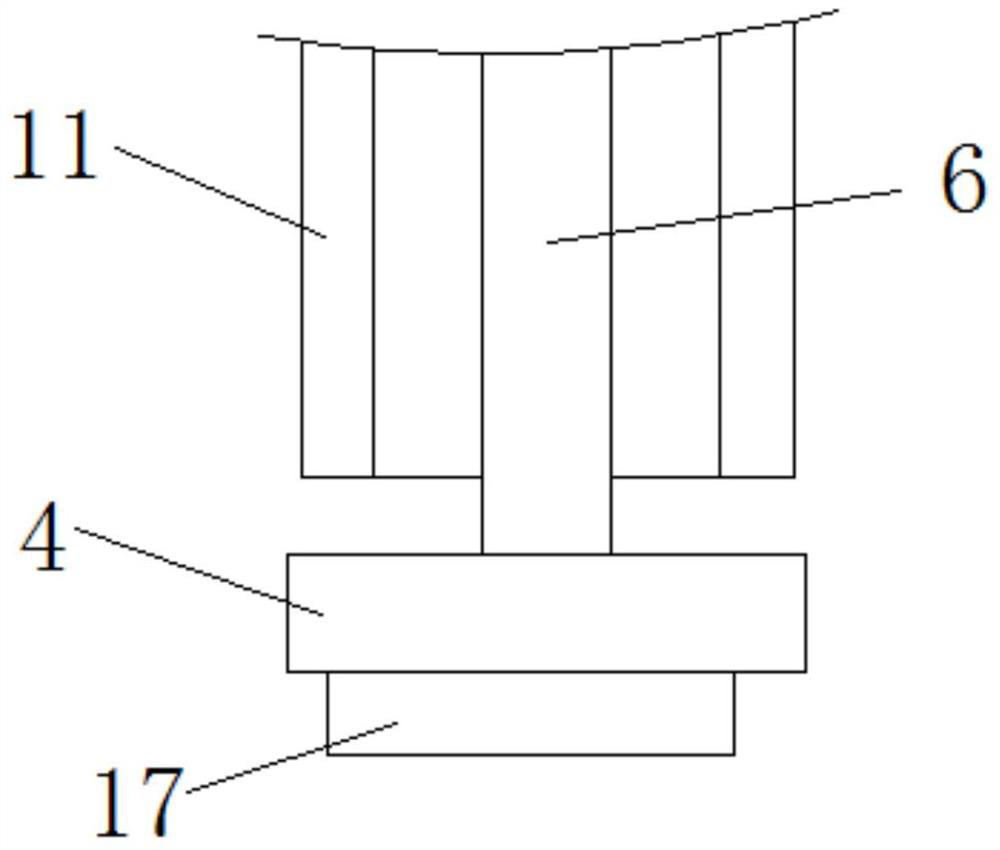

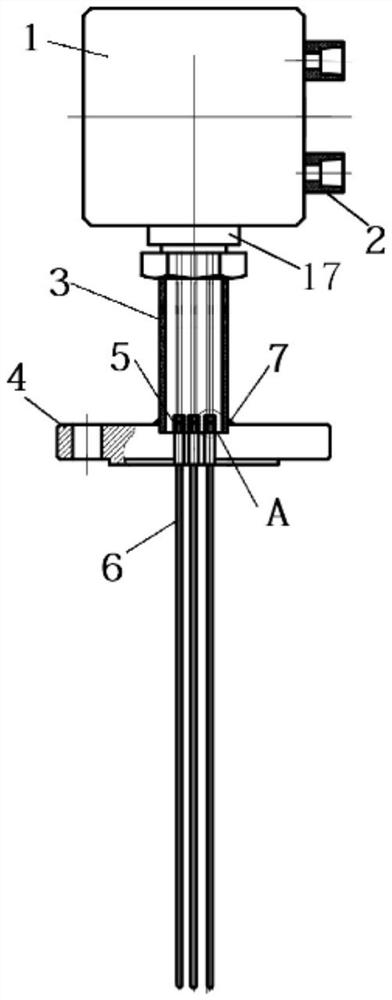

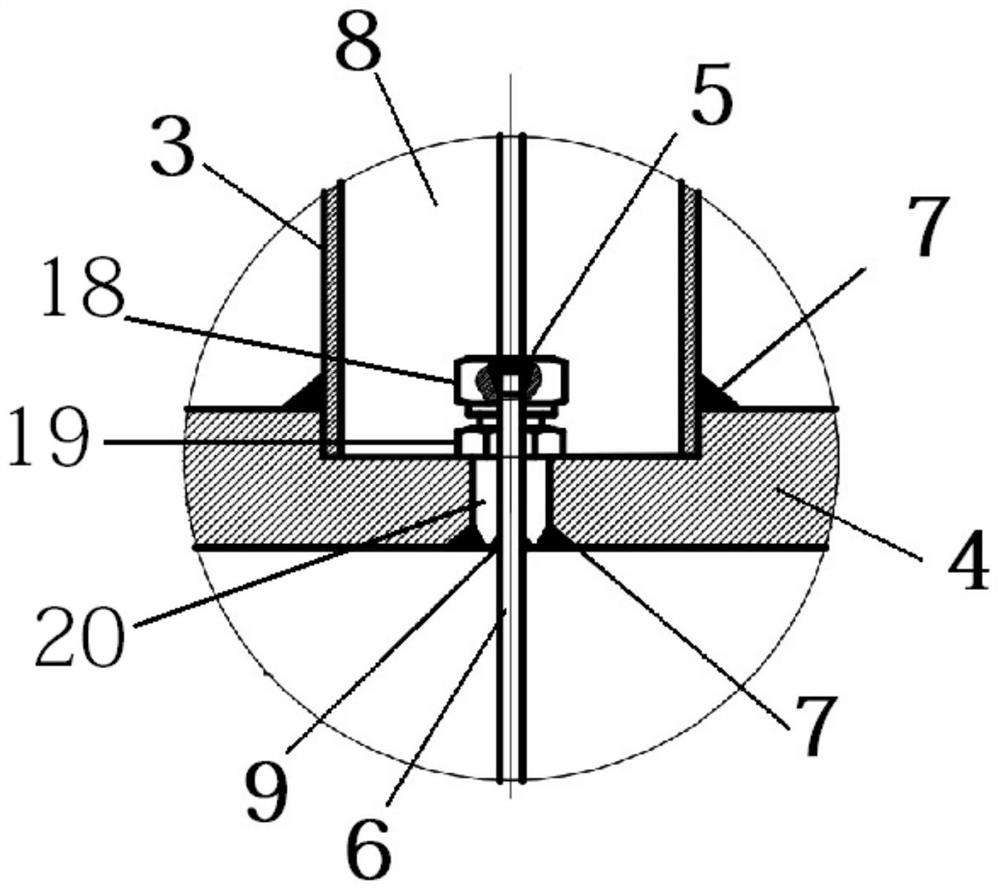

[0042] according to Figure 1-6 As shown, the embodiment of the present invention provides a reciprocating thermocouple, including: a temperature sensor 6 and a sleeve 11, one end of the temperature sensor 6 is connected to a swing cylinder 17, and the other end is arranged in the sleeve 11, And reciprocating rotation in the casing 11;

[0043] One end of the swing cylinder 17 close to the temperature sensor 6 is provided with a flange 4, and the side of the swing cylinder 17 away from the flange 4 is connected to the control box 1, the control box 1 is provided with a controller, and the controller uses The swing cylinder 17 is activated or deactivated, and the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com