Intelligent automatic food cutting equipment

A technology for cutting equipment and food, applied in the engineering field, can solve the problems of single function and low efficiency, and achieve the effect of changing the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

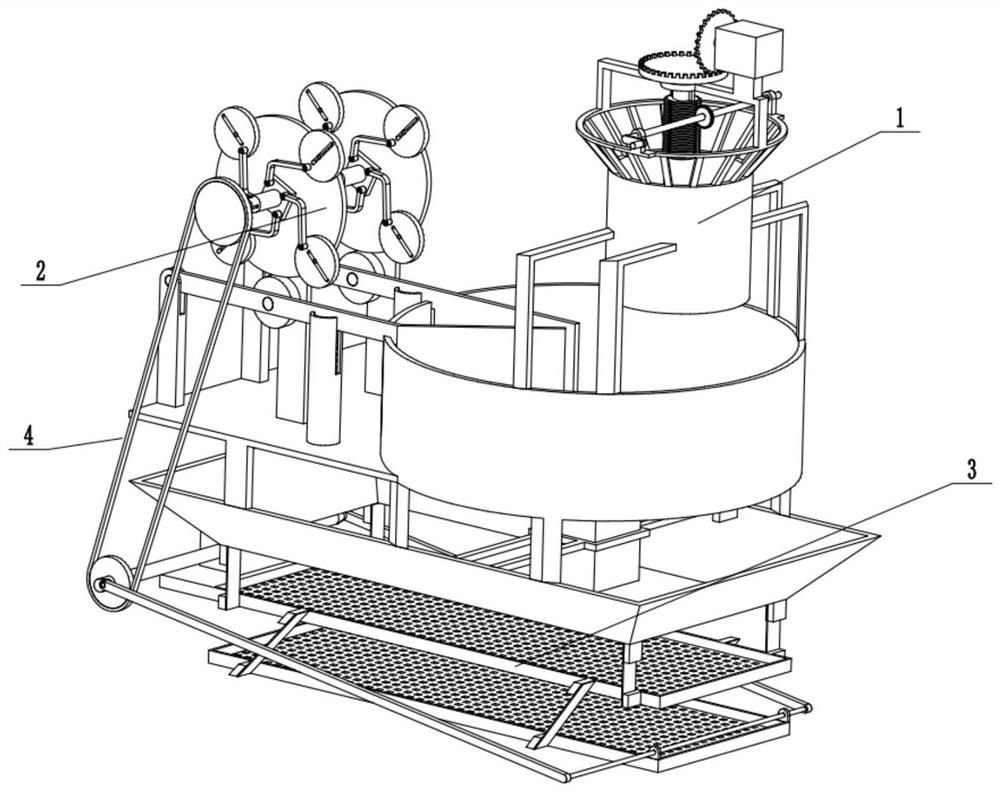

[0023] Combine below Figure 1-7 Describe this embodiment, an intelligent automatic food cutting equipment, including a rough cutting device 1, a chopping device 2, a screening and washing device 3, and a belt 4, the rough cutting device 1 is connected with the chopping device 2, and the chopping device 2 is connected with the screening device 3, the chopping device 2 is connected with the belt 4, and the screening device 3 is connected with the belt 4.

specific Embodiment approach 2

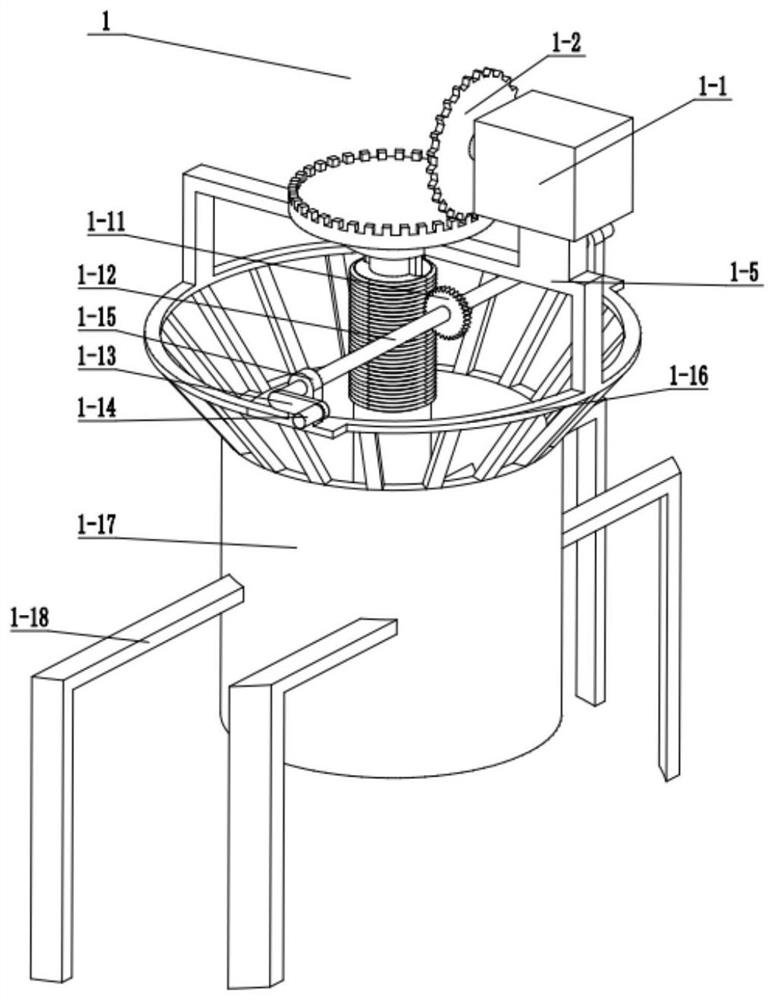

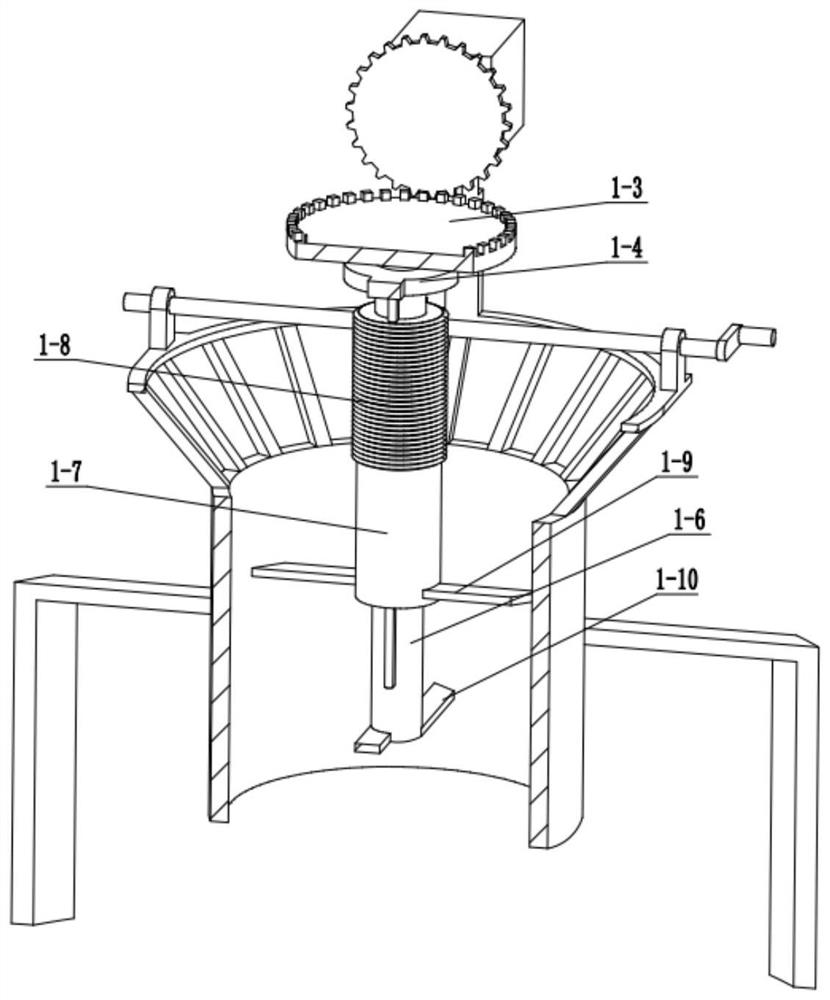

[0025] Combine below Figure 1-7 Describe this embodiment, this embodiment will further explain embodiment one, described rough cutting device 1 comprises motor one 1-1, gear one 1-2, gear two 1-3, fixed ring 1-4, support one 1 -5, inner shaft 1-6, outer shaft 1-7, round tooth 1-8, blade one 1-9, blade two 1-10, gear three 1-11, connecting rod one 1-12, connecting rod two 1 -13, connecting rod three 1-14, bracket two 1-15, fence one 1-16, cutting barrel 1-17, bracket three 1-18, motor one 1-1 is fixedly connected with gear one 1-2, gear one 1-2 is meshed with gear 2 1-3 for transmission, fixed ring 1-4 is fixedly connected with bracket 1-5, gear 2 1-3 is fixedly connected with inner shaft 1-6, inner shaft 1-6 is connected with outer shaft 1- 7 is connected in cooperation, the fixed ring 1-4 is rotationally connected with the inner shaft 1-6, the scalloped teeth 1-8 are arranged on the outer shaft 1-7, and the two blades 1-9 are fixedly connected with the outer shaft 1-7, and ...

specific Embodiment approach 3

[0028] Combine below Figure 1-7Describe this embodiment, this embodiment will further explain the first embodiment, the shredding device 2 includes motor two 2-1, bracket four 2-2, chassis one 2-3, chassis two 2-4, handle 2- 5. Fence 2 2-6, leg frame 1 2-7, runner 1 2-8, connecting inner rod 2-9, connecting outer rod 2-10, nut 2-11, functional block 2-12, large disc 2-13, curved rod 2-14, small disc 2-15, small cylinder 2-16, long slot 2-17, bracket five 2-18, long rod 2-19, runner two 2-20, small cylinder Two 2-21, chopping knife 2-22, square barrel 2-23, spring 2-24, leg frame two 2-25, bottom plate boss 2-26, motor two 2-1 is fixedly connected with support four 2-2, Motor two 2-1 is fixedly connected with chassis one 2-3, chassis two 2-4 is fixedly connected with handle 2-5, two chassis two 2-4 are all connected with chassis one 2-3, two chassis two 2- 4 are all slidably connected with fence two 2-6, chassis one 2-3 is slidably connected with fence two 2-6, four leg fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com