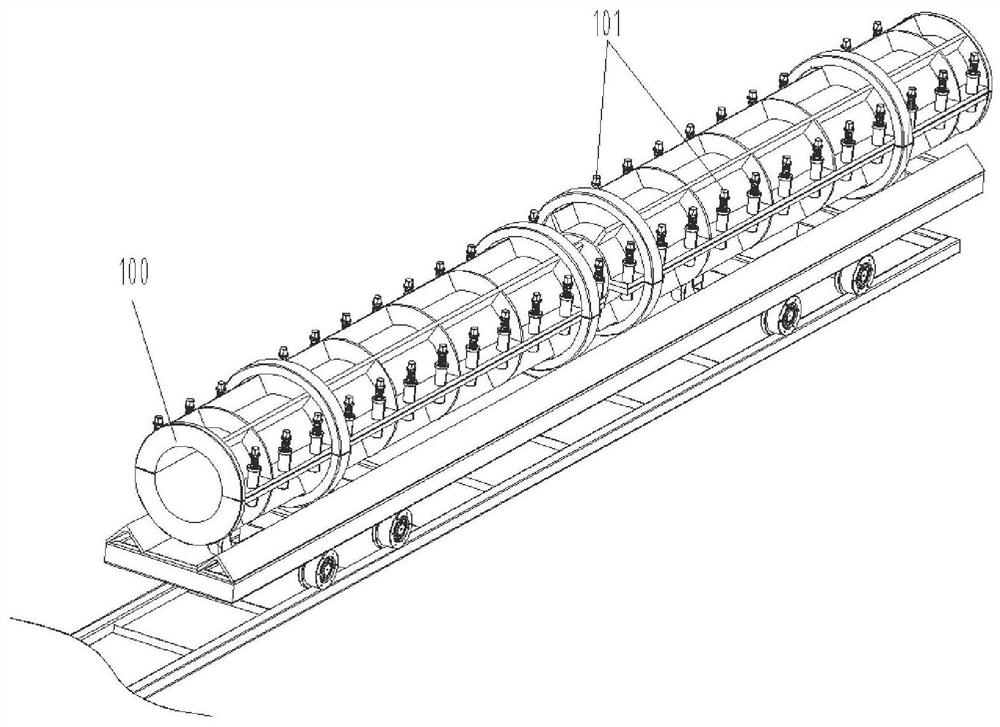

Pipe pile mold bolts automatically follow the circular cycle tightening mechanism without power

A technology of automatic following and pipe pile formwork, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of low production efficiency and limitation of pipe formwork forward speed, etc., and achieve strong practicability, good constraint coordination, Simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

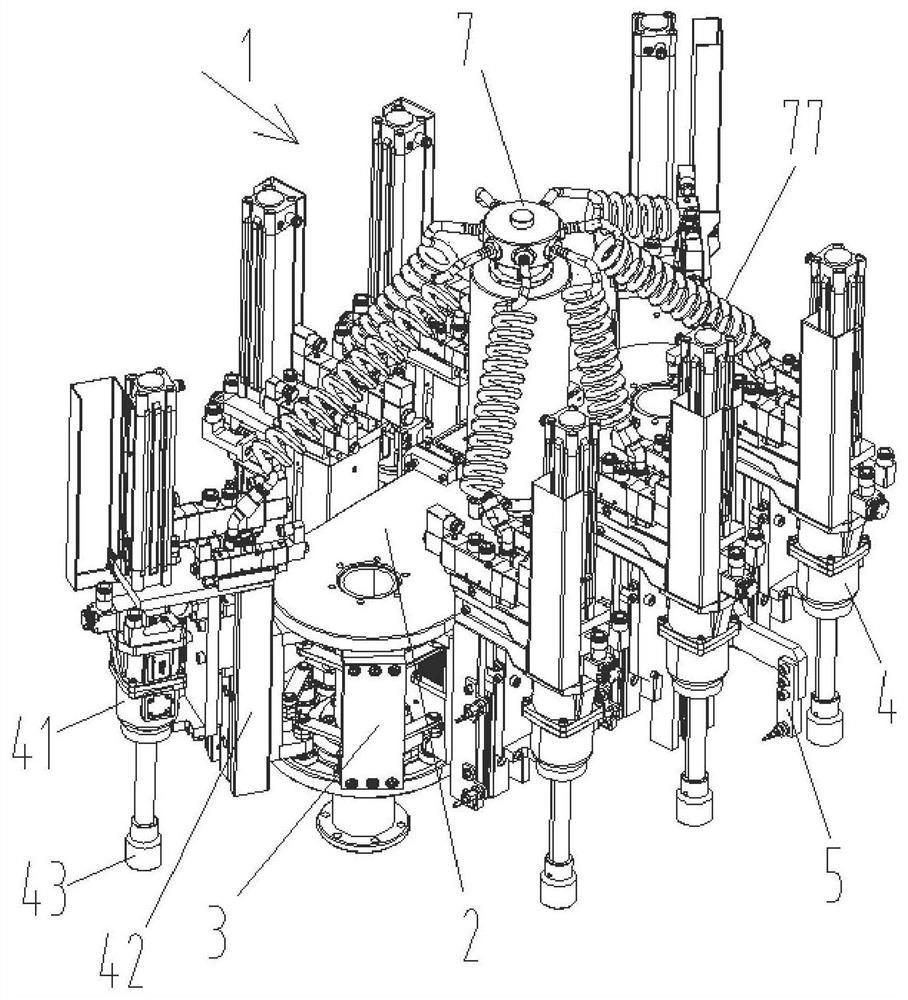

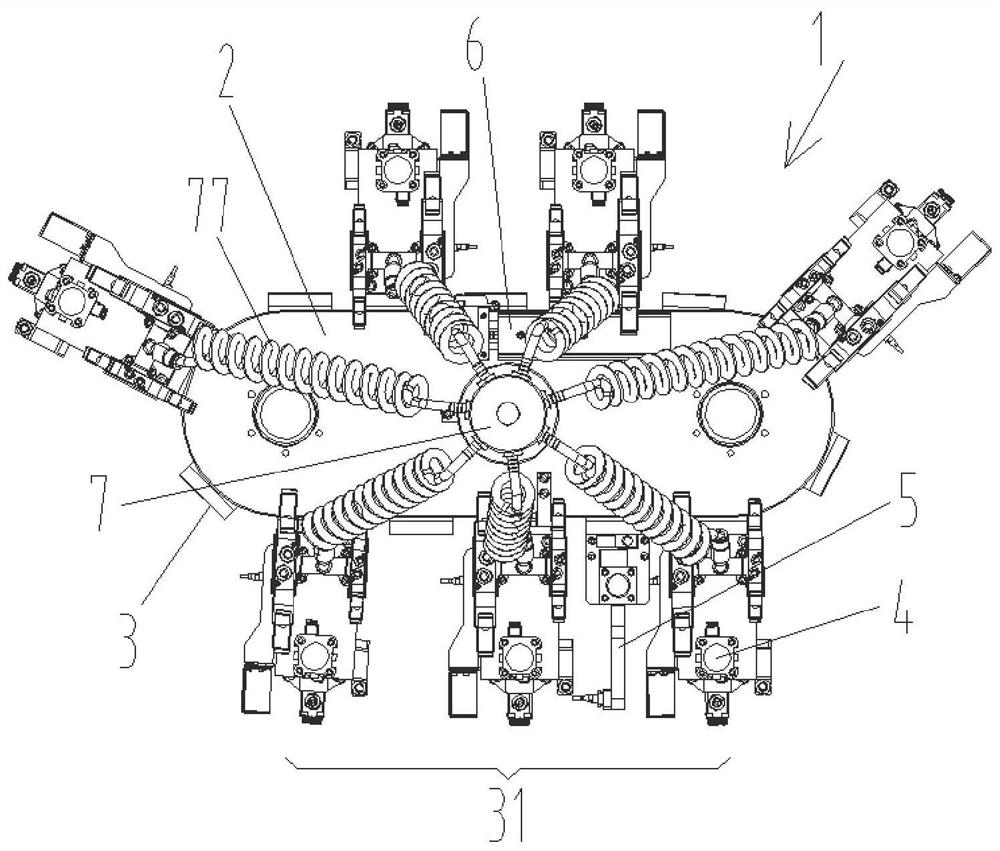

[0070] The following in conjunction with the accompanying drawings of specific embodiments of the present invention will be further described in detail.

[0071] See Figure 2 、 Figure 3 , the specific embodiment of the pipe pile die bolt without power automatically follows the ring circulation tightening mechanism 1, comprising a flexible chain link 3, the flexible chain link 3 is connected around the base frame 2 and under the action of the driving force can be rotated around the base frame 2; When the flexible chain link 3 rotates around the base frame 2, at least one section is always maintained as a straight state and the segment is formed as a straight working section 31;

[0072] The flexible chain link 3 is further spaced in the direction of length is provided with a plurality of assembly and dismantling units that can be lifted independently 4 for loading and disassembling the bolted unit on the pipe pile mold; The length of the straight working segment 31 is greater than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com