Prestressed and non-prestressed heat-shrinkable sleeve anti-corrosion anchor rod

A heat-shrinkable sleeve, non-prestressed technology, used in sheet pile walls, protection devices, buildings, etc., can solve problems such as no prestressed and non-prestressed heat-shrinkable sleeve anchors, and achieve simple coating The effect of protection, reliable transmission of tensile force and improvement of engineering quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

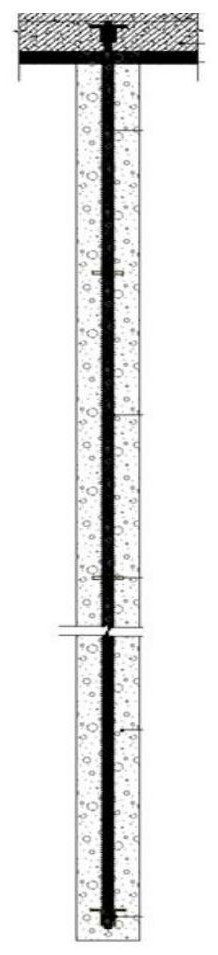

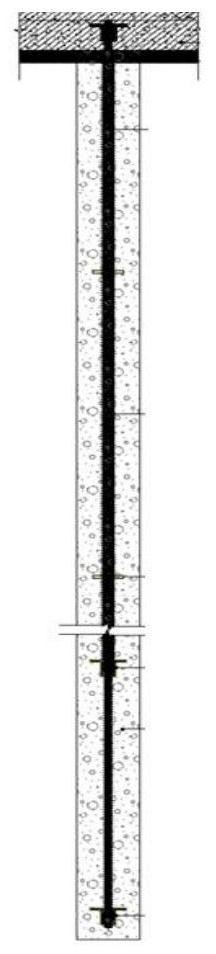

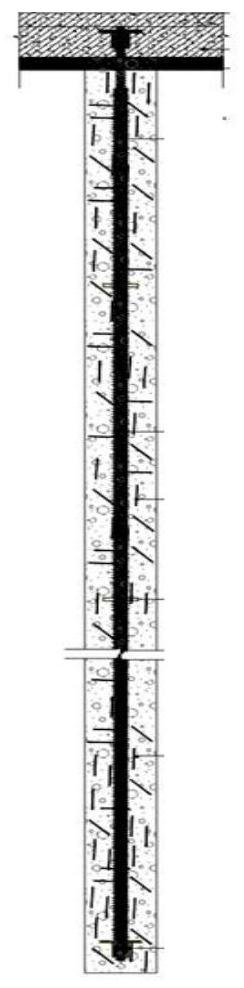

[0061] As shown, especially Figure 45-47 The notation, unmarked accompanying drawings all are various applications of the present invention; Anchor rod or claim anchor rod parts, concrete or mortar 4 after pouring anchor rod main steel bar 1, nut connector 2, heat-shrinkable sleeve 3, concrete or mortar The mortar 4 pours the prepared main reinforcement or the outer layer of the finished rough main reinforcement; the anchor rod or the end of the anchor rod can be provided with a fixing plate or a bearing plate.

[0062] The outer layer of the main reinforcement of the non-adhesive main reinforcement anchor is provided with an anti-corrosion grease layer, and can be provided with a thermoplastic film cover.

[0063] The heat-shrinkable sleeve 3 especially covers the nut connector, and two (above) prestressed or non-prestressed anchor rods are connected together through the connecting device; the connecting device is the main steel bar connecting the two anchor rods with the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com