Prefabricated combined assembled anti-floating tensile prestressed anchor rod piece and construction method thereof

A combined assembly and prestressing technology, applied in the installation of bolts, protection devices, infrastructure engineering, etc., can solve problems such as pulling cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

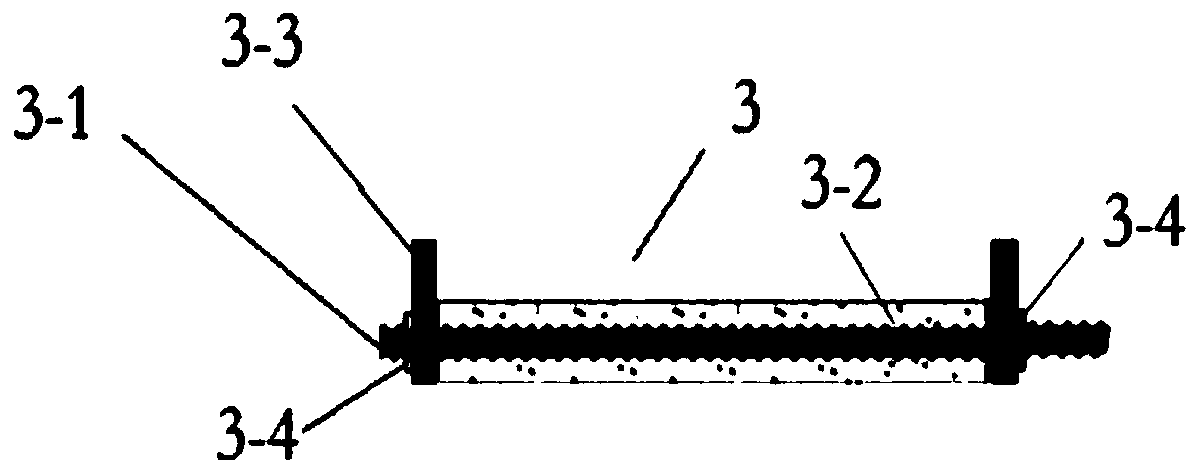

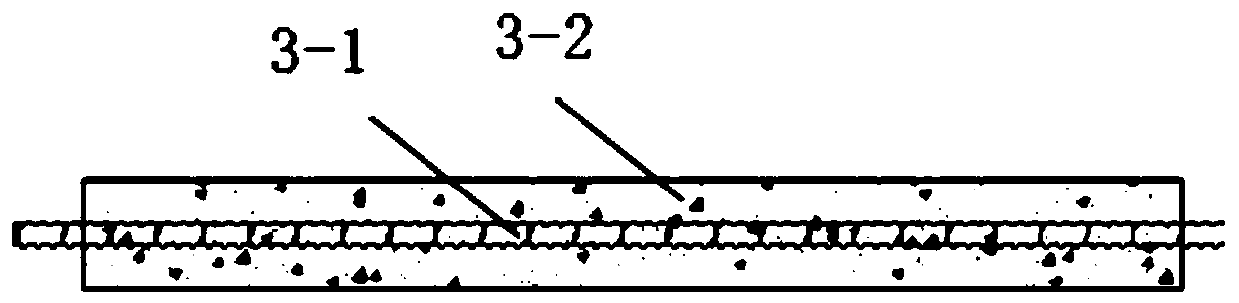

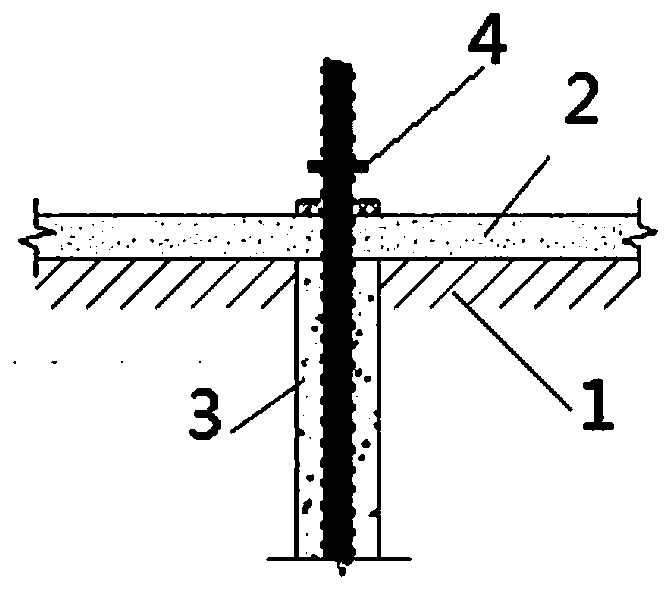

[0074]As shown in the figure, an example of parts in the figure: base 1, concrete cushion 2, anchor rod after pouring or called anchor rod 3, main reinforcement prepared by concrete or mortar pouring or pipe string 3-2 of the outer layer of thick rolled steel bar , fixed plate or bearing plate 3-4, prestressed nut 3-3, anti-corrosion grease layer 3-6, plastic film sleeve 3-5, limiter 11, flange nut assembly 16-1 are used on the bottom plate Fixed anchor rod reinforcement (main reinforcement or finish-rolled thick reinforcement) 3-1, when post-stressing, flange nut assembly 16-1 is to fix the prestress of main reinforcement or finish-roll thick reinforcement after applying stress. Waterstop rubber strip 4, flange nut 16, concrete bottom plate 8, concrete bottom plate reinforcement 8-1, bottom plate cushion 8-2, and steel cage 10 can be straight-through or enlarged head structure, and the figure is variable diameter The enlarged diameter steel cage structure. Grouting body 12, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com