Elastic reset device

An elastic reset device and reset block technology, applied in the field of boilers, can solve the problems affecting the elastic reset function, easy access, failure of elastic parts of the elastic reset device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

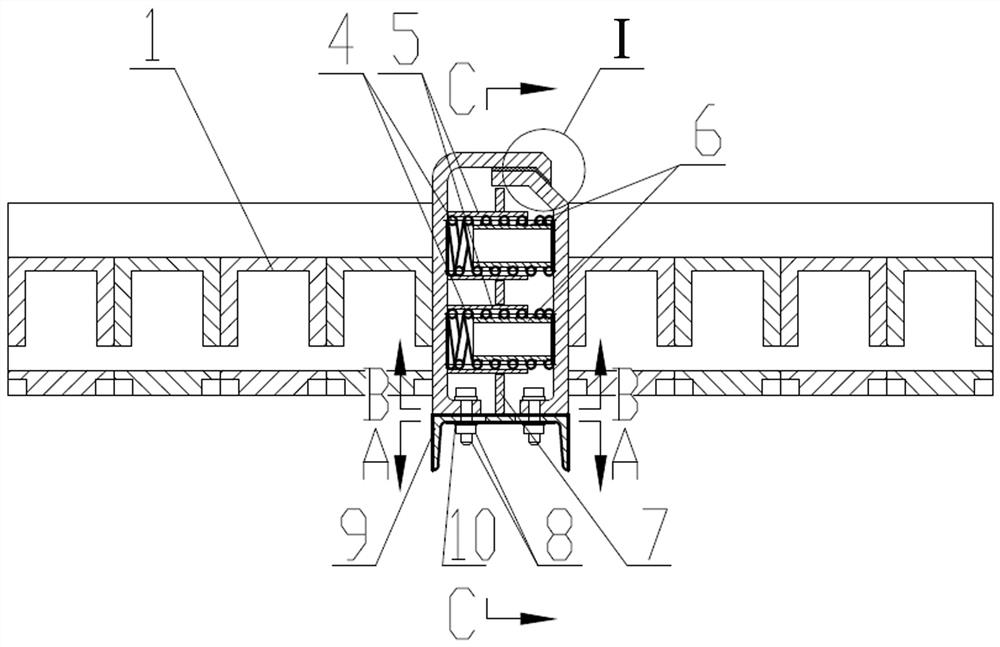

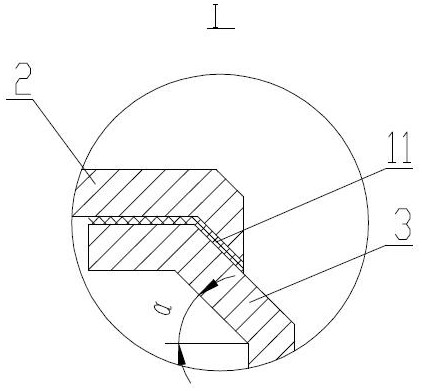

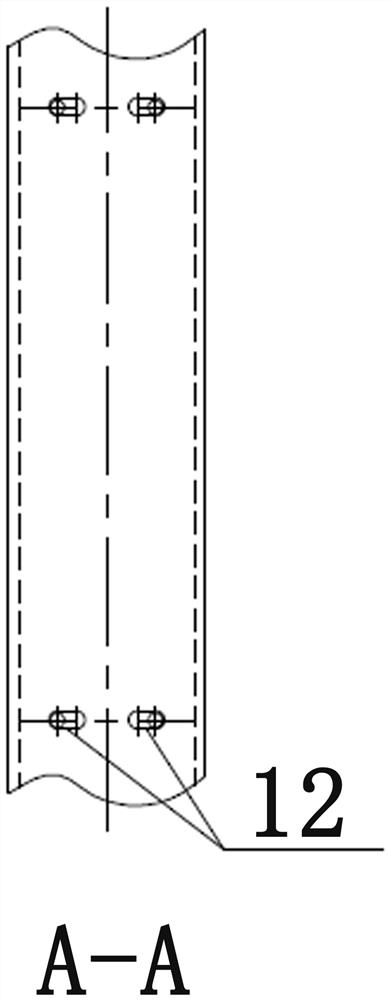

[0020] Such as figure 1 As shown, the elastic reset device of the present invention is arranged in the middle of the grate piece 1, and includes a reset block, a spring 4, a sleeve and a guide plate 7. The reset block is divided into a left reset block 2 and a right reset block 3, such as figure 2 As shown, the upper ends of the left and right reset blocks are partially overlapped, and a knuckle is provided at the overlap, and the knuckle α is not less than 45°, and ceramic fiber blanket 11 is filled at the knuckle. Springs 4 and sleeves are evenly arranged inside the elastic reset device, and the sleeves are divided into an outer sleeve 5 and an inner sleeve 6, which are fixedly connected with the left and right reset blocks respectively, and the outer sleeve 5 and the inner sleeve 6 are installed between the outer sleeve 5 and the inner sleeve 6. The spring 4 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com