Device for measuring surface shape tolerance of curved surface lining plate of cylindrical surface steel support

A technology of surface shape and steel support, which is used in measuring devices, mechanical measuring devices, and mechanical devices, etc., can solve problems such as inability to measure workpieces, and achieve the effects of convenient detection, fast and accurate alignment, and low detection accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

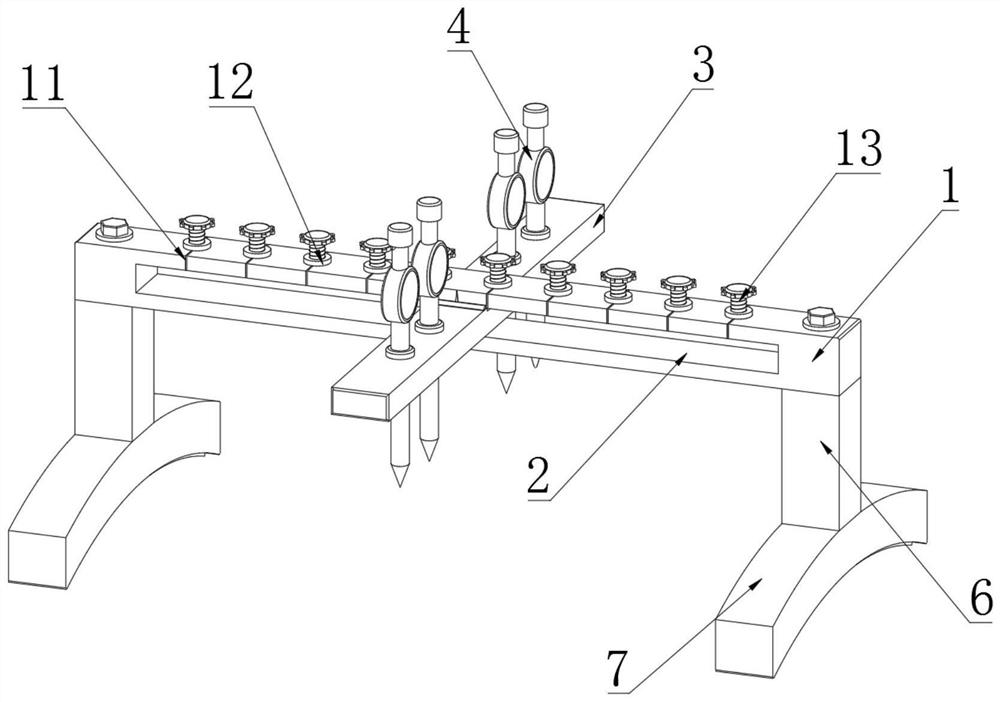

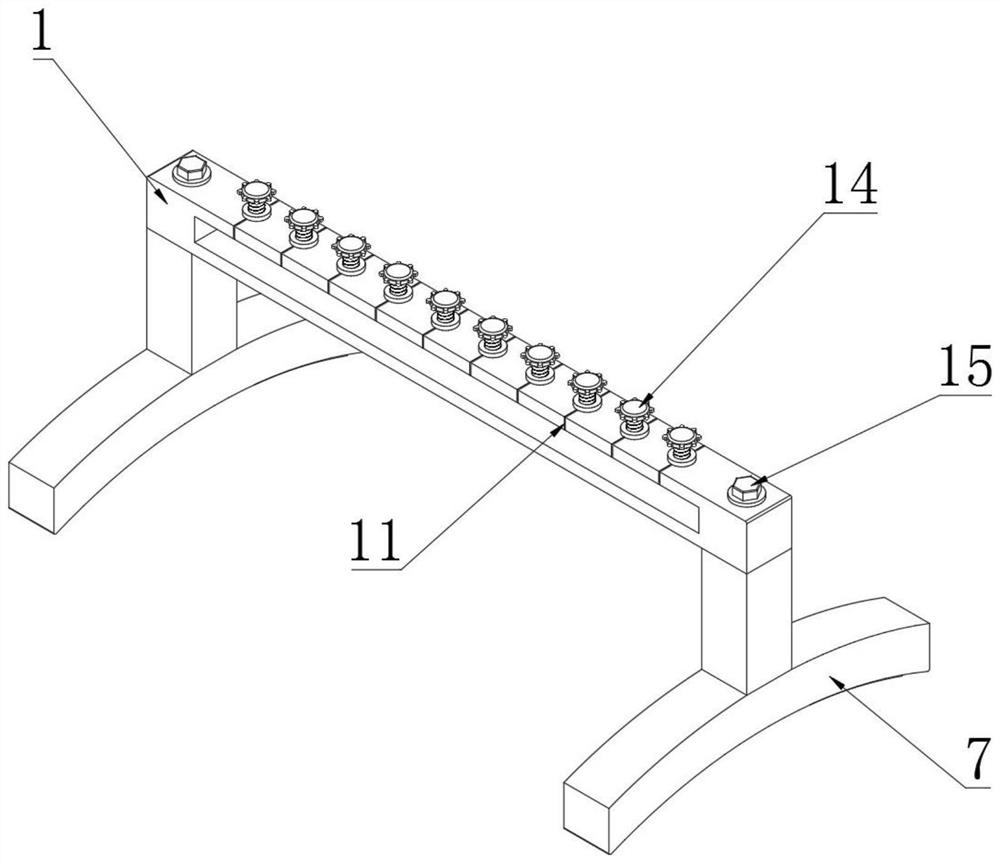

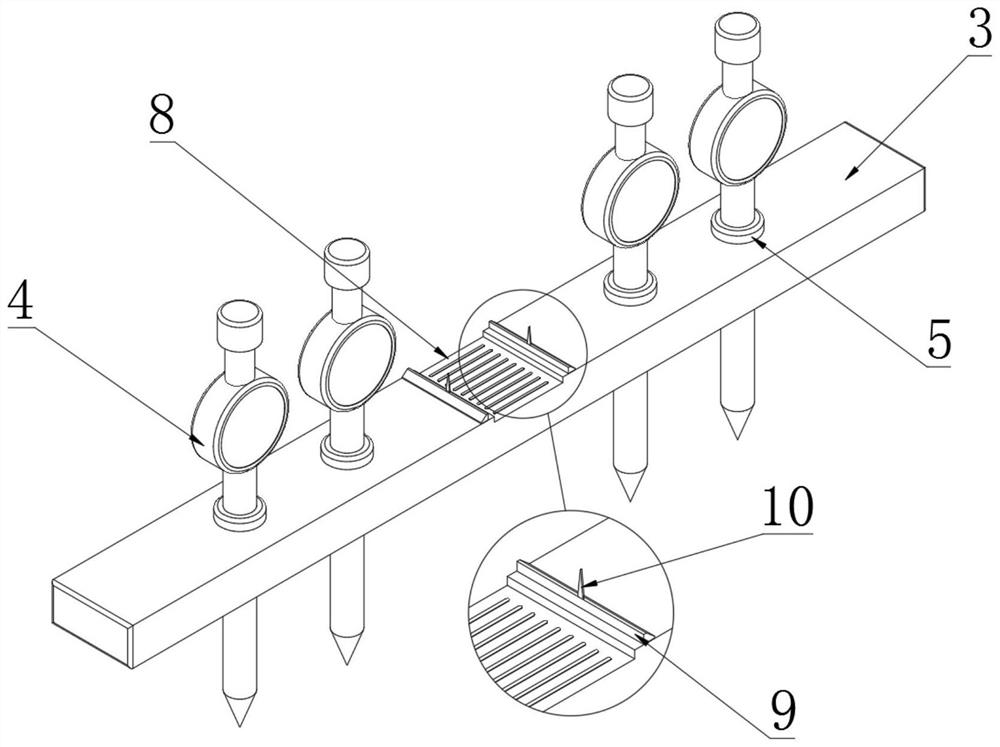

[0034] Example: such as Figure 1-3As shown, the present invention provides a technical solution, a device for measuring the surface shape tolerance of the curved liner of a cylindrical steel support, including a transverse support frame 1 and a longitudinal support plate 3 that slides laterally on the inner side of the transverse support frame 1, and the transverse support The interior of the frame 1 is horizontally provided with a transverse chute 2 for sliding the longitudinal support plate 3, the longitudinal support plate 3 is embedded and slidably connected to the inner side of the transverse chute 2, and the edge of the longitudinal support plate 3 fits with the inner wall of the transverse chute 2, and the longitudinal support plate 3 The inside of the support plate 3 is located on both sides of the horizontal support frame 1 and is provided with connection holes. There are four connection holes, and two sides of the horizontal support frame 1 are located inside the lon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com