Fatigue damage evaluation device for nuclear turbine blade

A technology for steam turbine blades and fatigue damage, which is applied in the field of fatigue damage assessment devices for nuclear power steam turbine blades, can solve problems such as single external structure, delay of steam turbine efficiency, and inability to fix blades well, so as to achieve good practicability and increase practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

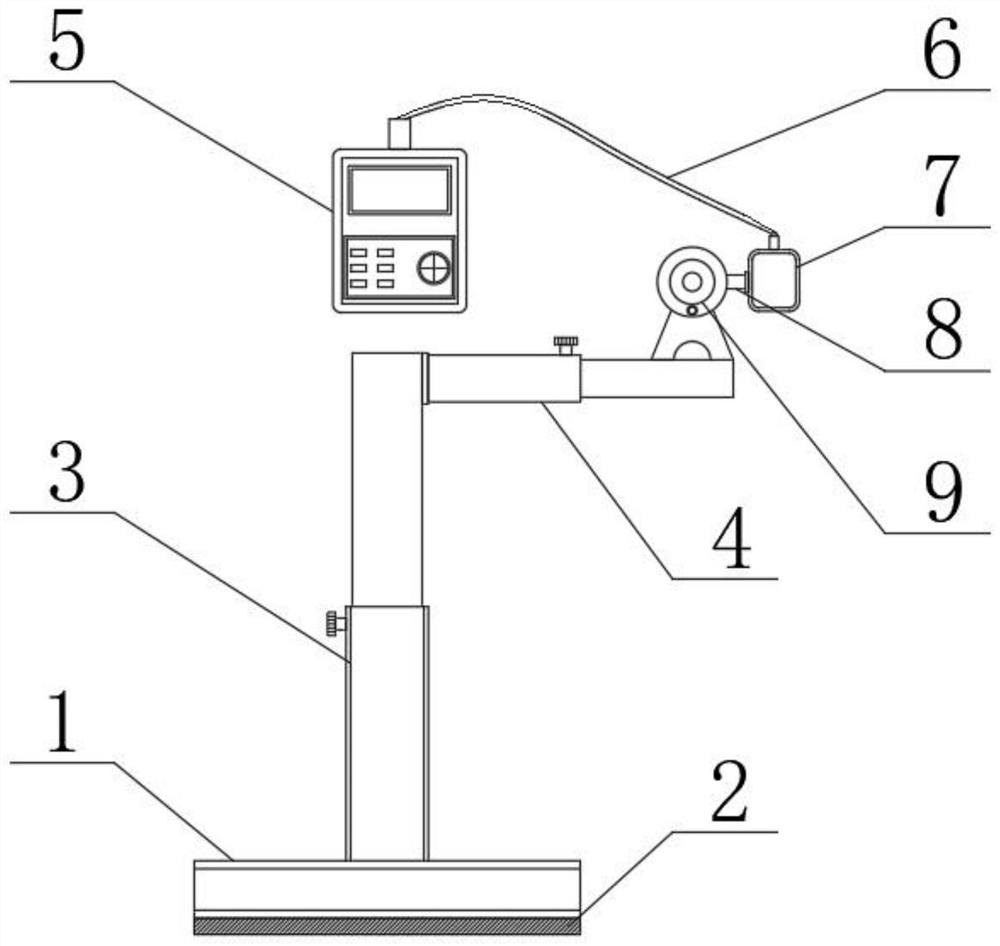

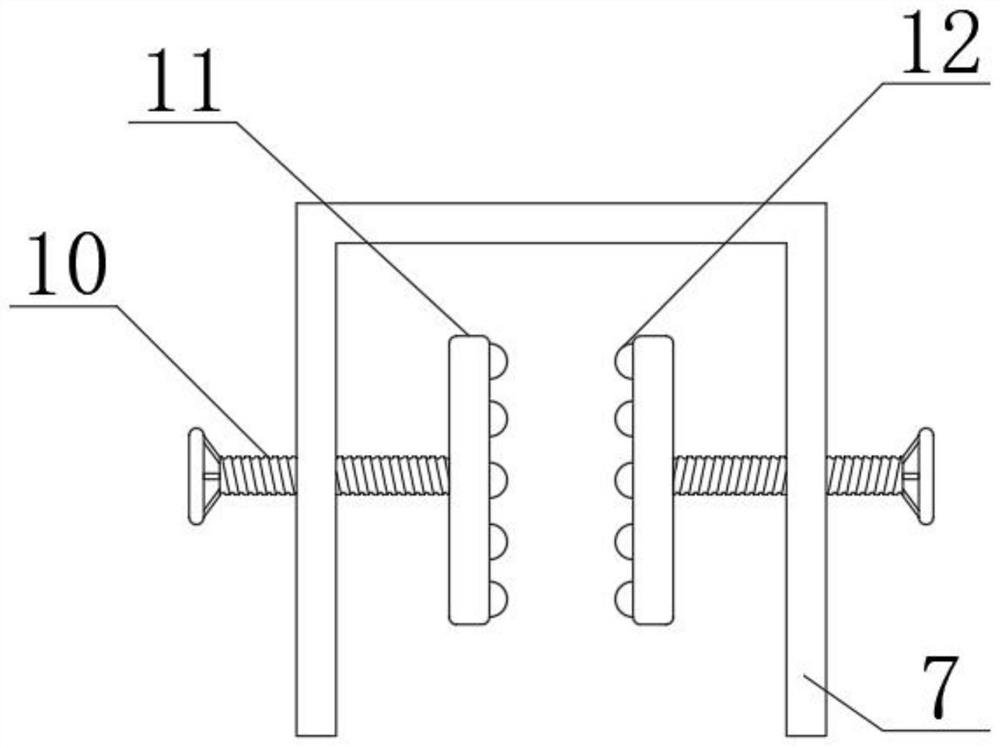

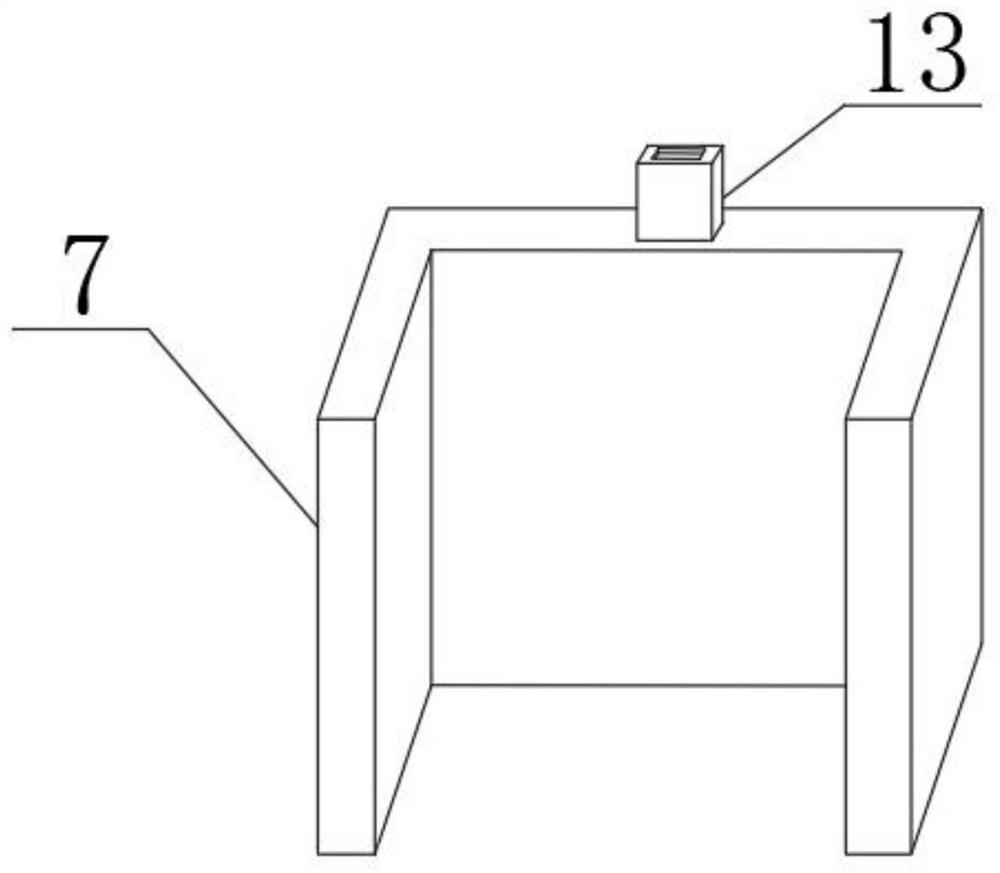

[0022] See Figure 1-5 The present invention provides the following technical solution: the fatigue damage evaluation apparatus of nuclear power turbine blades, including support base 1 and 1 support rod 3, and the upper side of the support base 1 is provided with a vibration measuring device 5, and the vibration measuring device 5 is connected inside one side connection There is a transmission wire 6, and the outer surface of the No. 1 support rod 3 is bonded to the No. 2 support rod 4, and the outer surface of the second surface of the second support rod 4 is rotated through the support 15, and the shaft 9 is connected. On the side, the fixed block 7 is bonded to the fixing block 7, and the inside of the fixed block 7 is spinned and connected to the adjustment bolt 10, and the outer surface of the adjustment bolt 10 is rotated by the bearing 14, and the fixed plate 11 is connected inside. Turning a plurality of balls 12, the outer surface side of the fixed block 7 is bonded to a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com