Touch device and adjusting method thereof

A touch and push rod technology, which is applied in transportation and packaging, contact operation parts, remote control aircraft, etc., can solve problems such as button damage, difficulty in controlling the force of pressing the button device, and abnormal operation of the button, so as to improve reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

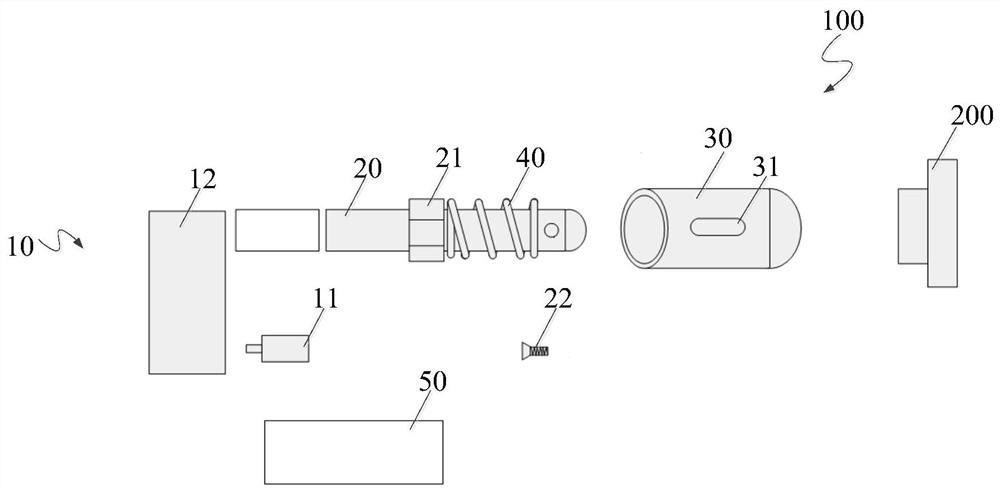

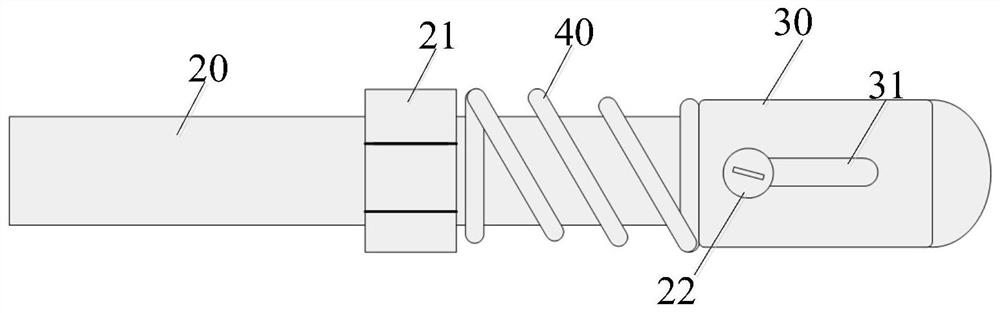

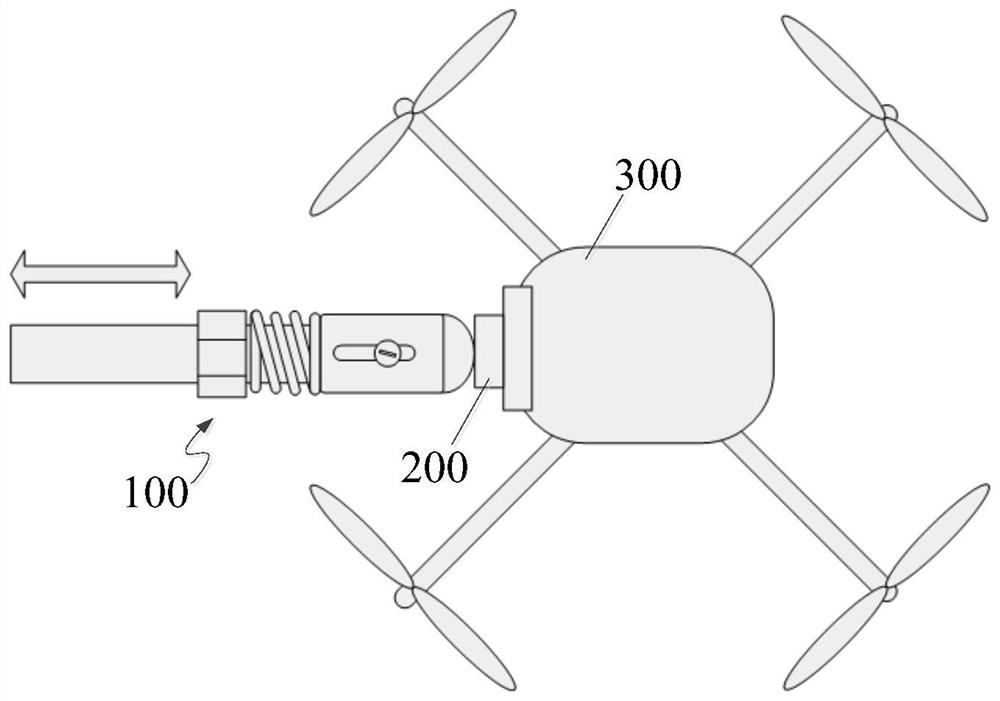

[0031] reference figure 1 , 2 The structure of the touch device 100 shown and the application scenario, the embodiment of the present invention provides a touch apparatus 100, which comprises: a power source 10 that provides power for touch device 100.

[0032] The touch device 100 also includes a push rod 20, and the power source 10 is connected to the first end of the push rod 20, and the drive push rod 20 is reciprocated. Alternatively, the push rod 20 is a straight rod, and the power source 10 drives the push rod 20 to reciprocate in its rod extension direction, specifically, the push rod 20 moves in the direction of the button device 200 and the remote button device 200.

[0033] The touch device 100 also includes a pressing cap 30 that is set to the second end of the push rod 20 in the pressing cap 30, and the top of the compression cap 30 is used to press the button apparatus 200, and the cap body is pressed on the cap 30. 31. Pressing the cap 30 for contact with the button ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com