Side flapping sickbed for postoperative auxiliary nursing of hepatobiliary pancreatic surgery

A post-surgical, hepatobiliary technology, applied in the field of hospital beds, can solve problems such as labor and trouble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

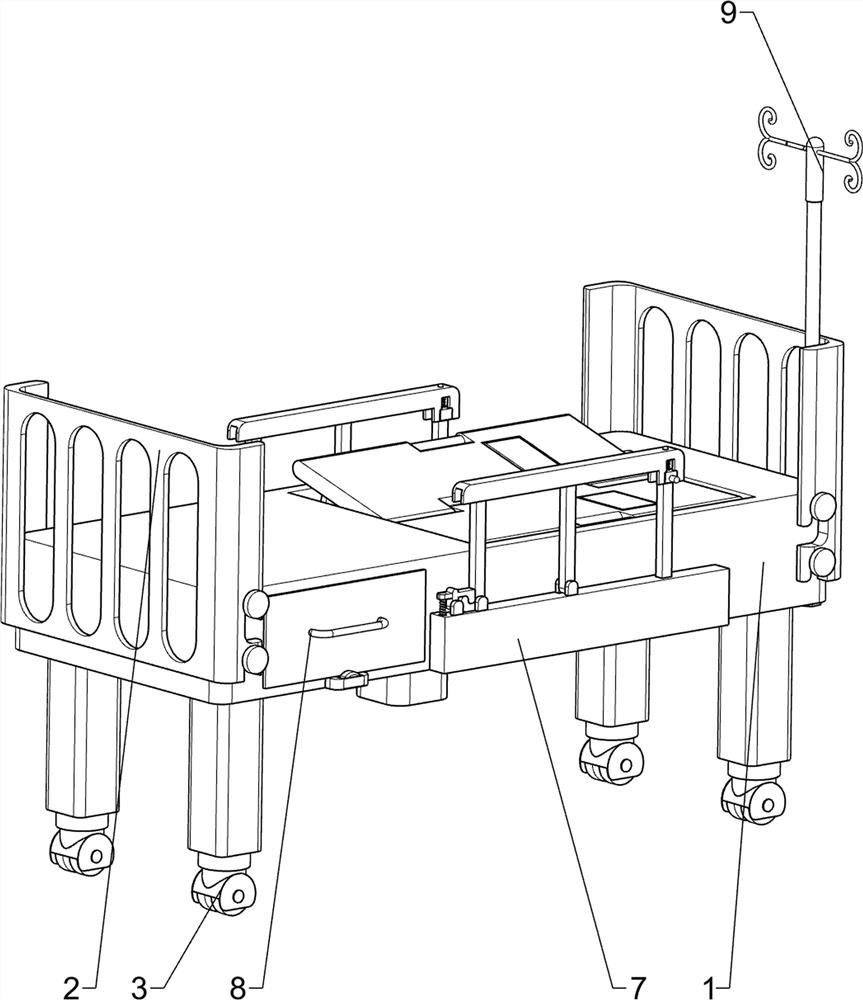

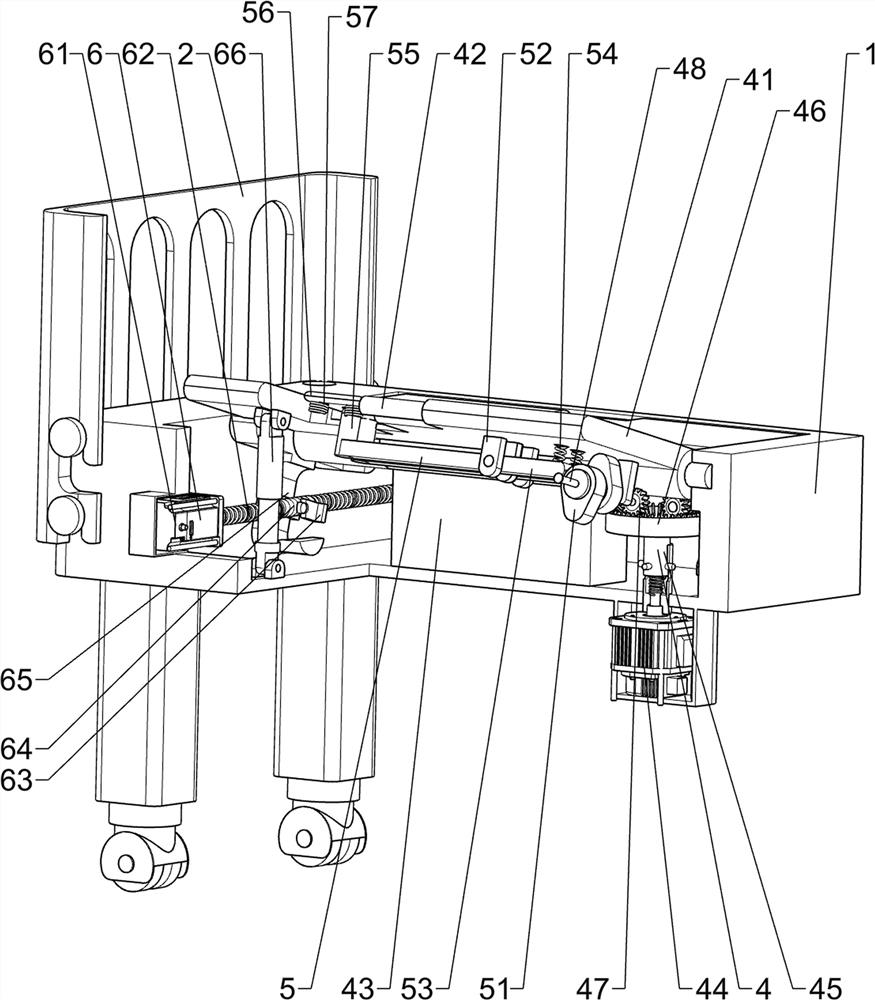

[0024] A sideways flapping hospital bed for auxiliary nursing after hepatobiliary and pancreatic surgery, such as figure 1 and figure 2 As shown, it includes a bed frame 1, a protective baffle plate 2, a wheel column 3, a driving mechanism 4 and a knocking mechanism 5, and four wheel columns 3 are fixedly connected to the outer bottom of the bed frame 1 at even intervals in the circumferential direction, and the bed frame 1 Outer left part and right part are all detachably placed with protective baffle 2, bed frame 1 middle part is provided with driving mechanism 4, and driving mechanism 4 is provided with knocking mechanism 5, and knocking mechanism 5 cooperates with driving mechanism 4.

[0025] The drive mechanism 4 includes a swinging bed board 41, a force-bearing grip bar 42, a support block 43, a constant speed motor 44, a spring drive shaft 45, an internal tooth drive disc 46, a gear 47 and a rotating shaft 48, and the upper side of the right part of the bed frame 1 is...

Embodiment 2

[0031] On the basis of Example 1, such as Figure 1-Figure 4 As shown, it also includes a rollover auxiliary mechanism 6. The rollover auxiliary mechanism 6 includes a servo motor 61, a screw mandrel 62, a slider 63, an internally threaded sleeve 64, a T-shaped block 65 and a supporting hydraulic column 66. The coaxial right side of the swinging bed board 41 is equipped with a T-shaped block 65 in the circumferential rotation type, and the left and right sides of the T-shaped block 65 bottom are slidingly provided with a slide block 63, and the left and right sides slide blocks 63 are rotatable. Internally threaded shaft sleeve 64 is connected, servo motor 61 is installed on the right side of the rear side of bed frame 1, and the output shaft end of servo motor 61 is fixedly connected with screw mandrel 62, and the front end of screw mandrel 62 is connected with bed frame 1 inner front side right side. Rotational connection, two swinging bed boards 41 bottom outer sides and be...

Embodiment 3

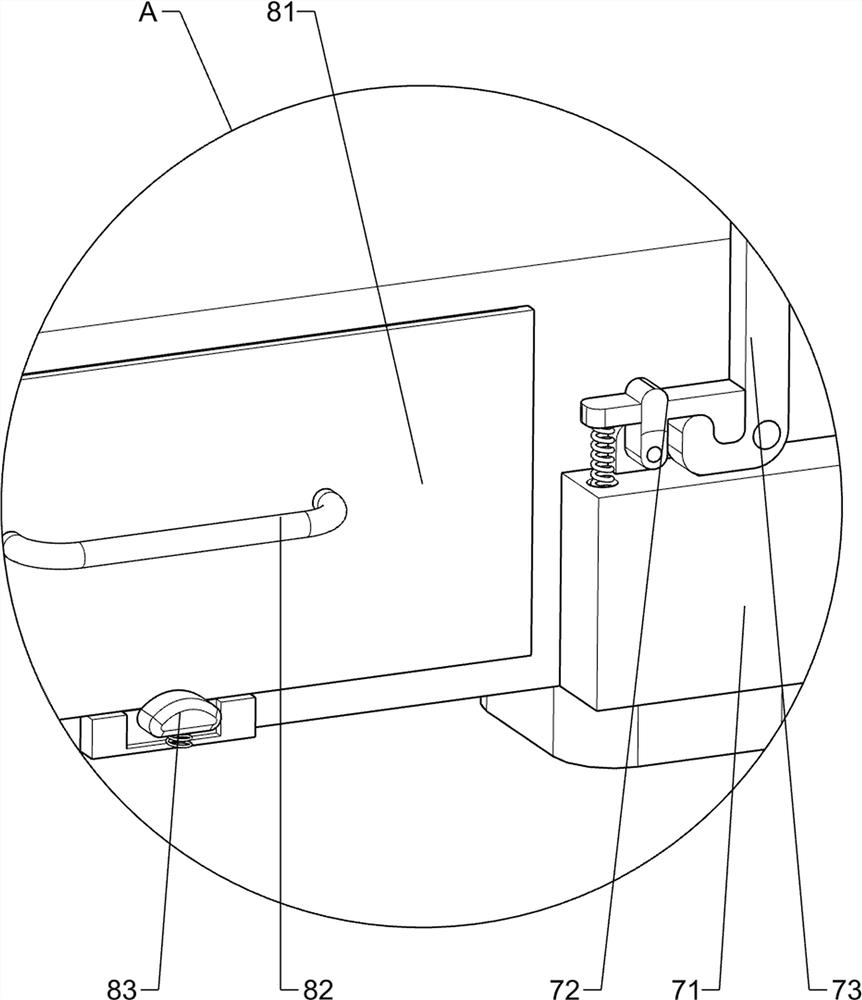

[0036] On the basis of embodiment 1 and embodiment 2, such as figure 1 , image 3 and Figure 4 As shown, a storage mechanism 8 is also included, and the storage mechanism 8 includes a storage drawer 81, a handle 82 and a spring block 83. The sliding type embedded in the left side of the front side of the bed frame 1 is placed with a storage drawer 81, and the storage drawer 81 outside A handle 82 is fixedly connected to the middle part of the front side, and a spring block 83 is fixedly connected to the lower left side of the outer front side of the bed frame 1, and the spring block 83 contacts and cooperates with the storage drawer 81.

[0037] Also include a liquid hanging mechanism 9, the liquid hanging mechanism 9 includes a drip suspension rod 91, a positioning bolt 92 and a hanging claw hook 93, and the embedded sliding type of the front part of the bed frame 1 right side places a drip suspension rod 91, and the drip suspension rod 91 is placed on the drip suspension r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com