A cavitation venturi

A Venturi tube and cavitation technology, applied in the field of aerodynamics, can solve the problems of large fluid pressure loss and easy jamming of the valve core in the throat of the Venturi tube shell, etc., to reduce pressure loss and reduce jamming in the throat Part and can not move the spool, to ensure the effect of stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

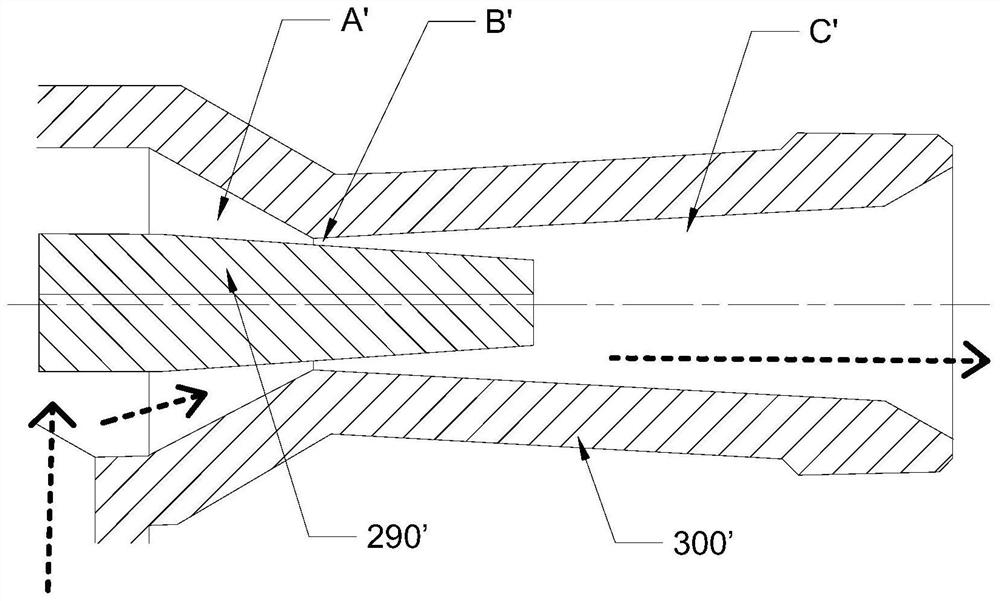

[0051] For the above issues, see figure 2 image 3 and Figure 4 , Figure 8 As shown, this embodiment provides a cavitation venturi, including a valve core 290 and a venturi casing 300, wherein: the flow channel in the venturi casing 300 includes constricted sections that communicate in sequence along the fluid flow direction A, the throat B and the expansion section C, the valve core 290 is movably arranged to cooperate with the throat B to adjust the flow rate of the fluid; the valve core 290 has a conical part, and the conical part extends from the expansion section C through the throat to the contraction section A, and the radial section of the tapered portion tends to decrease along the direction from the expansion section C to the contraction section A;

[0052] Among them, the "contraction section" refers to the radial cross-sectional area of the inner profile surface of the venturi casing 300 gradually shrinking along the fluid flow direction, and the "expansion...

specific Embodiment approach

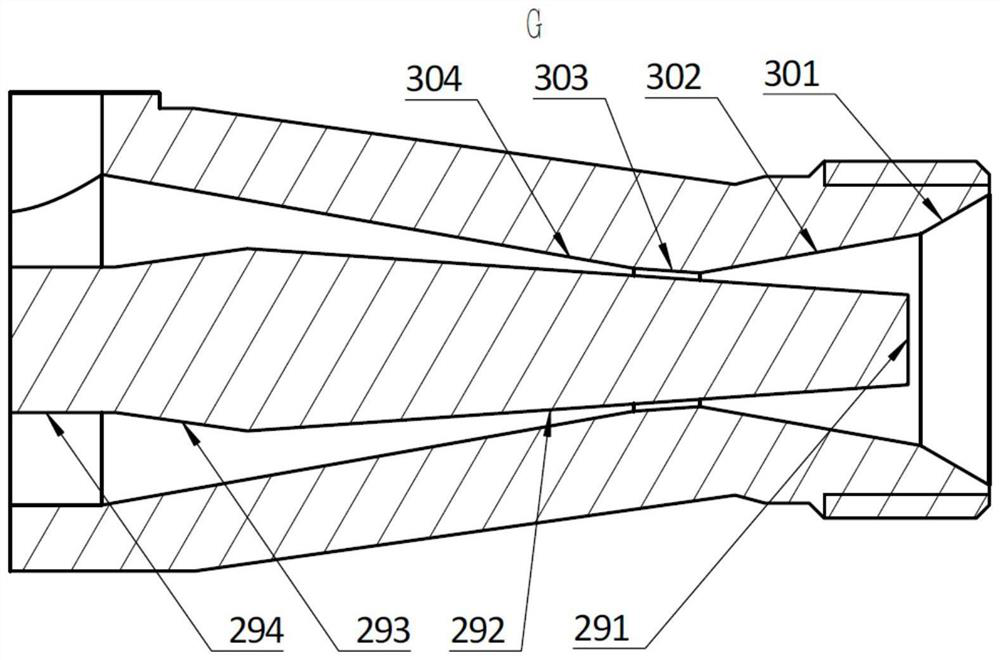

[0056] In this embodiment, the specific structure of the valve core 290 is as follows: see Figure 2-Figure 4 shown, see image 3 , the outer wall surface of the valve core 290 includes a needle cone surface 292, a needle cone shrinking surface 293 and a cylindrical surface 294 which are sequentially connected along its axial direction. The minimum flow section of the flow channel is formed; the part where the cylindrical surface 294 is located is connected with a driving mechanism used to drive the valve core 290 to move, and the diameter of the needle-cone constricting surface 293 decreases along the direction from the needle-cone surface 292 to the cylindrical surface 294. Reduce the radial section of the cylindrical surface 294; preferably, the diameter of the conical constriction surface 293 gradually decreases along the direction from the conical surface 292 to the cylindrical surface 294; the end of the valve core 290 close to the fluid inlet is also formed with a trunc...

Embodiment 2

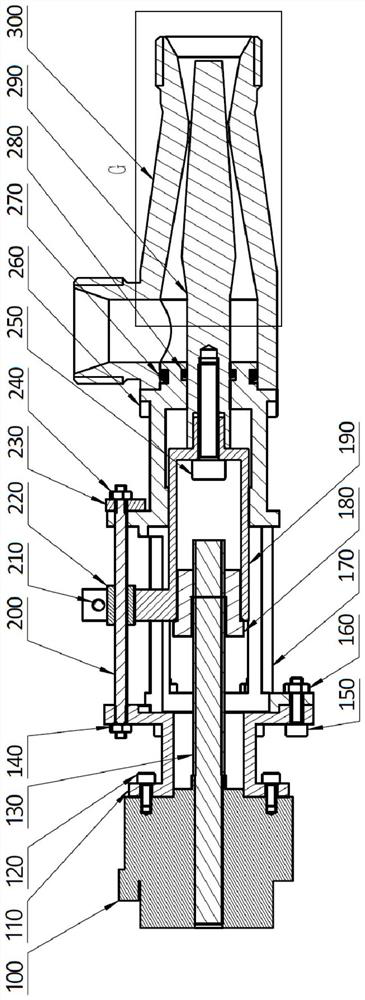

[0082] This embodiment is an improvement on the basis of the above-mentioned first embodiment. This embodiment provides a specific implementation of a driving mechanism, see figure 2 , Figure 4 , Figure 5 , Image 6 As shown, the cavitation venturi also includes a drive mechanism, and the drive mechanism includes a drive device, a lead screw 130, a lead screw nut 180 and a drive block 190, wherein: the output shaft of the drive device is connected with the lead screw 130, and the lead screw 130 is connected to the lead screw 130. The lead screw nut 180 is threadedly connected, one end of the driving block 190 is fixedly connected to the lead screw nut 180, and the other end is fixedly connected to the valve core 290. When the driving device rotates forwardly and reversely, the lead screw 130 and the lead screw nut 180 can cooperate with each other. The structure drives the driving block 190 and the valve core 290 to reciprocate and linearly move in the axial direction.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com