A ghost elimination method for head-up display

A technology for eliminating ghosting and head-up display, applied in the field of head-up display, can solve the problems of high cost, strict angle of wedge-shaped film, and high modification cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

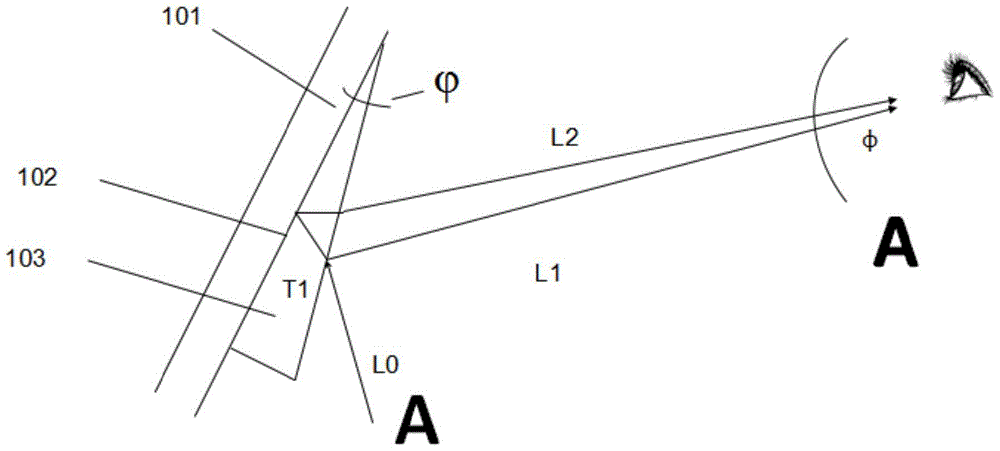

[0037] like figure 2 As shown, it is the structure and optical path schematic diagram of the front windshield 101 of the automobile and the ghost elimination plate 103 that adopts the triangular light-transmitting plate in the method of the present invention, and the optical glue 102 is a silicone adhesive (Kraft K-5505H, Shenzhen Zhiyantong Technology Co., Ltd.). The center thickness of the ghost canceling plate 103 is 1.357 mm. The material of the ghost elimination plate 103 is polyethylene terephthalate. The cross-section of the ghost elimination plate 103 along its thickness direction is triangular, that is, a triangular light-transmitting plate is used.

[0038] The inclination angle of the front windshield glass of general consumer models is in the range of [40,50], and the horizontal distance between the front windshield glass and the driver is [0.75m, 0.9m]. Therefore, in order to facilitate calculation, the inclination angle Φ of the front windshield 101 of the au...

Embodiment 2

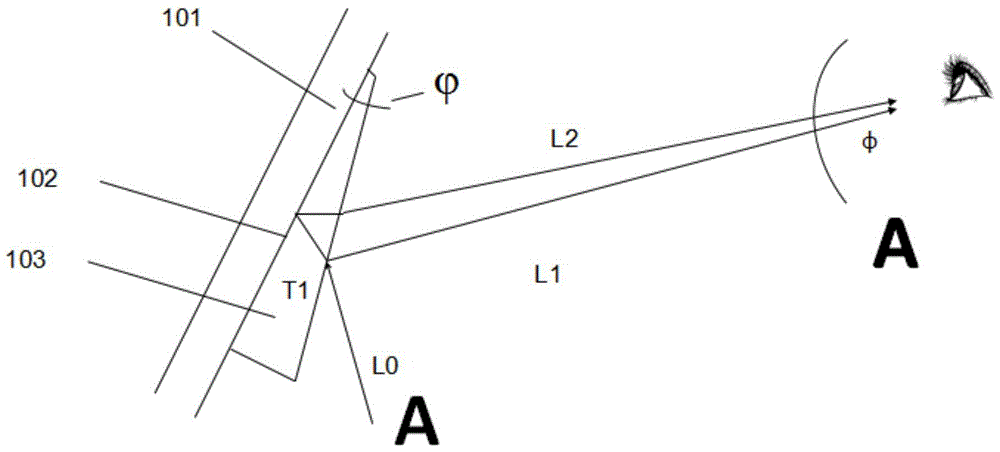

[0044] like image 3 As shown, it is the structure and optical path schematic diagram of the front windshield 101 of the automobile and the ghost elimination plate 103 that adopts the wedge-shaped light-transmitting plate in the method of the present invention, and the optical glue 102 is a silicone adhesive (Kraft K-5505H, Shenzhen Zhiyantong Technology Co., Ltd.). The center thickness of the ghost canceling plate 103 is 0.607 mm. The material of the ghost elimination plate 103 is polyethylene terephthalate. The cross-section of the ghost elimination plate 103 along its thickness direction is trapezoidal, that is, a trapezoidal light-transmitting plate is used.

[0045] The inclination angle of the front windshield glass of general consumer models is in the range of [40,50], and the horizontal distance between the front windshield glass and the driver is [0.75m, 0.9m]. Therefore, for convenience of calculation, the inclination angle Φ of the front windshield 101 of the aut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com