Batch preparation method of nicotine salt and application of nicotine salt in electronic cigarette

A nicotine salt, batch technology, applied in the field of electronic cigarettes, can solve the problems of high cost and inability to realize mass production of nicotine salt, and achieve the effects of reduced irritation, increased satisfaction, and clean and comfortable aftertaste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

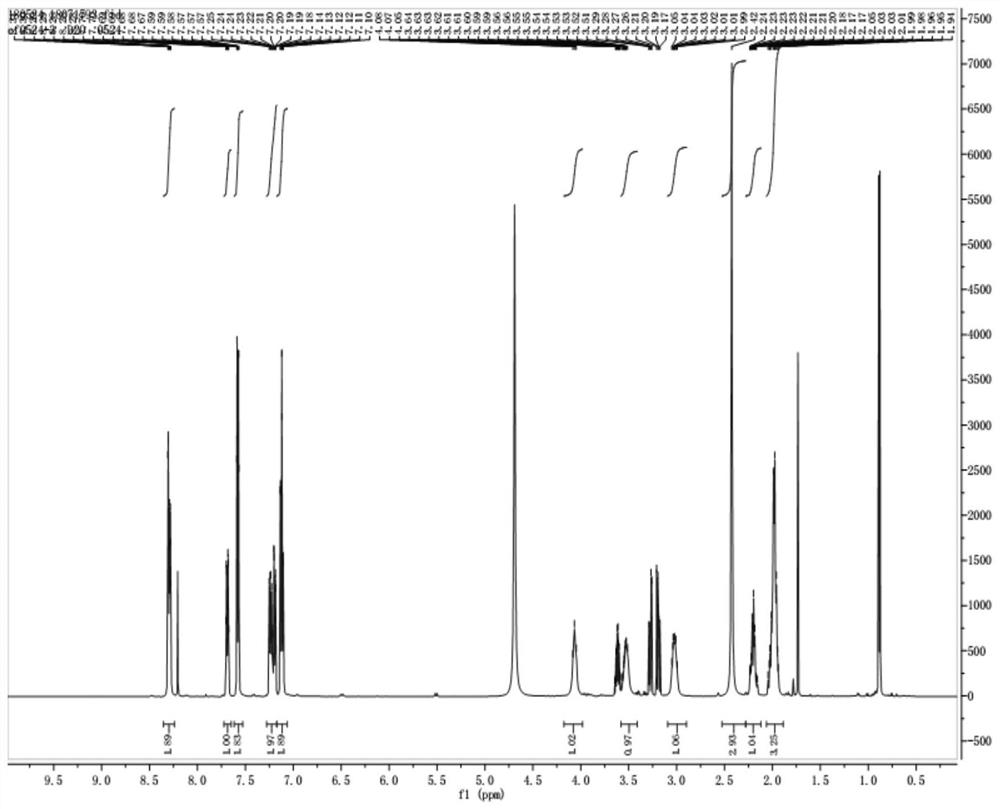

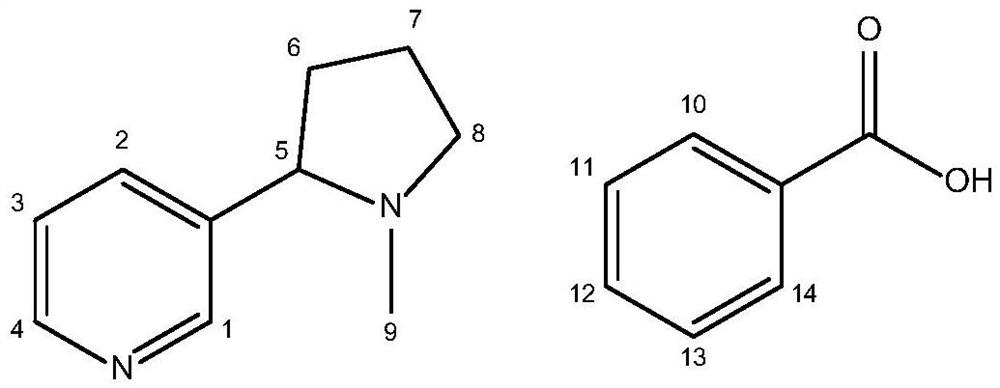

Image

Examples

Embodiment 1

[0016] Step 1) The cigarette powder is placed in a supercritical extraction device for extraction, the extraction medium is propylene glycol, the extraction pressure is 20Mpa, the temperature is 45°C, and the extraction time is 1.5h;

[0017] Step 2) First stage molecular distillation, heating temperature 85°C, second stage molecular distillation, heating temperature 100°C, third stage molecular distillation, heating temperature 130°C;

[0018] Step 3) Weigh 1 kg of Class A tertiary fraction of tobacco powder and place it in a container; weigh 2 kg of ethyl acetate, pour it into the container, and stir it evenly; weigh 0.6 kg of water, pour it into the container, stir it evenly; let it stand for 10 Minutes, after layering, separate the liquids, remove the lower aqueous phase, and leave the upper ethyl acetate phase;

[0019] Step 4) add benzoic acid to the ethyl acetate phase, the amount of benzoic acid is 0.862n, fully stir evenly. Weigh 2 kg of water, add it into the soluti...

Embodiment 2

[0024] Step 1) Put the cigarette powder in a supercritical extraction device for extraction, the extraction pressure is 25Mpa, the temperature is 35°C, and the extraction time is 2h;

[0025] Step 2) First stage molecular distillation, heating temperature 90°C, second stage molecular distillation, heating temperature 100°C, third stage molecular distillation, heating temperature 130°C;

[0026] Step 3) Weigh 1 kg of Class A tertiary fraction of tobacco powder and place it in a container; weigh 2 kg of ethyl acetate, pour it into the container, and stir evenly; weigh 0.6 kg of water and 0.01 kg of sodium chloride, pour it into the container, Stir evenly; let stand for 10 minutes, separate the liquid after layering, remove the lower aqueous phase, and keep the upper ethyl acetate phase;

[0027] Step 4) add benzoic acid in the ethyl acetate phase, the amount of benzoic acid is 0.862kg, fully stir evenly. Weigh 2 kg of water, add it into the solution, and stir evenly. Let it st...

Embodiment 3

[0029] Step 1) Put the cigarette powder in a supercritical extraction device for extraction, the extraction pressure is 30Mpa, the temperature is 55°C, and the extraction time is 3h;

[0030] Step 2) first stage molecular distillation, heating temperature 100°C, second stage molecular distillation, heating temperature 110°C, third stage molecular distillation, heating temperature 150°C;

[0031] Step 3) Weigh 1 kg of Class A tertiary fraction of tobacco powder and place it in a container; weigh 2 kg of ethyl acetate, pour it into the container, and stir it evenly; weigh 0.6 kg of water, pour it into the container, stir it evenly; let it stand for 10 Minutes, after layering, separate the liquids, remove the lower aqueous phase, and leave the upper ethyl acetate phase;

[0032] Step 4) add benzoic acid in the ethyl acetate phase, the amount of benzoic acid is 0.862kg, fully stir evenly. Weigh 2 kg of water, add it into the solution, and stir evenly. Stand still for 10 minutes,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap