A kind of preparation method of high-strength corrosion-resistant industrial filter cloth

A corrosion-resistant, high-strength technology, applied in the field of preparation of high-strength corrosion-resistant industrial filter cloths, can solve the problems of uncertainty, complexity, and reduced filtering effect of filter cloth materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

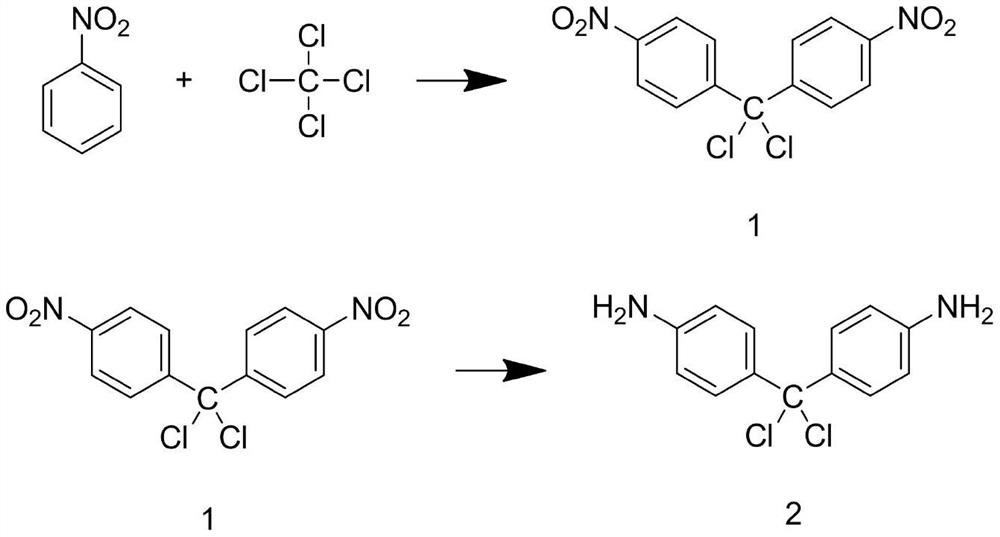

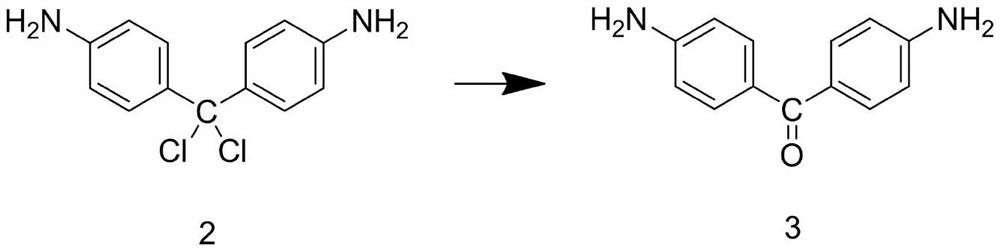

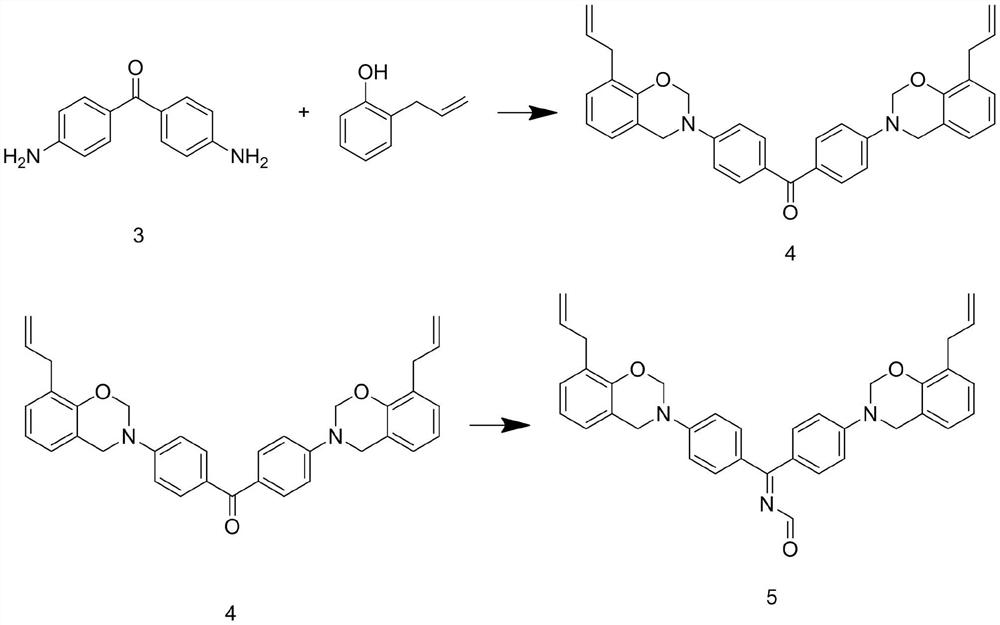

Image

Examples

Embodiment 1

[0037] A method for preparing a high-strength corrosion-resistant industrial filter cloth, specifically comprising the following steps:

[0038] Step S1: adding PET polyester chips, reinforcing granules, corrosion-resistant granules, and plasticizer into an extruder, and melt extruding to obtain polyester fibers;

[0039] Step S2: Weaving the polyester fiber into cloth to obtain a high-strength corrosion-resistant industrial filter cloth.

[0040] Described reinforcing granule is made by following steps:

[0041] Step A1: Add aluminum trichloride and carbon tetrachloride into the reaction kettle, stir and add nitrobenzene at a temperature of 10°C at 150r / min, and react at a temperature of 40°C 1h, to prepare intermediate 1, add intermediate 1, iron powder, and ethanol to the reaction kettle, under the condition of 80°C, reflux for 3h, add hydrochloric acid solution, add time 20min, continue to react for 5h, adjust The pH value of the reaction solution was 7, and Intermediate...

Embodiment 2

[0049] A method for preparing a high-strength corrosion-resistant industrial filter cloth, specifically comprising the following steps:

[0050] Step S1: adding PET polyester chips, reinforcing granules, corrosion-resistant granules, and plasticizer into an extruder, and melt extruding to obtain polyester fibers;

[0051] Step S2: Weaving the polyester fiber into cloth to obtain a high-strength corrosion-resistant industrial filter cloth.

[0052] Described reinforcing granule is made by following steps:

[0053] Step A1: Add aluminum trichloride and carbon tetrachloride into the reaction kettle, stir and add nitrobenzene under the condition of turning to 150r / min and temperature of 15°C, and react under the condition of temperature of 40°C 1.5h to prepare intermediate 1, add intermediate 1, iron powder, and ethanol to the reaction kettle, under the condition of 80°C, reflux reaction for 5h, then add hydrochloric acid solution for 20min, continue to react for 5h, Adjust the ...

Embodiment 3

[0061] A method for preparing a high-strength corrosion-resistant industrial filter cloth, specifically comprising the following steps:

[0062] Step S1: adding PET polyester chips, reinforcing granules, corrosion-resistant granules, and plasticizer into an extruder, and melt extruding to obtain polyester fibers;

[0063] Step S2: Weaving the polyester fiber into cloth to obtain a high-strength corrosion-resistant industrial filter cloth.

[0064] Described reinforcing granule is made by following steps:

[0065] Step A1: Add aluminum trichloride and carbon tetrachloride into the reaction kettle, stir and add nitrobenzene at a temperature of 15°C at 200r / min, and react at a temperature of 45°C 1.5h to prepare intermediate 1, add intermediate 1, iron powder, and ethanol into the reaction kettle, under the condition of 85°C, reflux reaction for 5h, then add hydrochloric acid solution for 20min, continue to react for 8h, Adjust the pH value of the reaction solution to 8 to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com