Flue gas multi-effect bag type dust removal system

A bag-type dust removal and flue gas technology, which is applied in the direction of gas treatment, combustion method, and dispersed particle filtration, etc., can solve the problems of environmental pollution, poor treatment effect, and low dust treatment efficiency, so as to improve the dust removal effect and improve the dust removal efficiency efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0028] Example

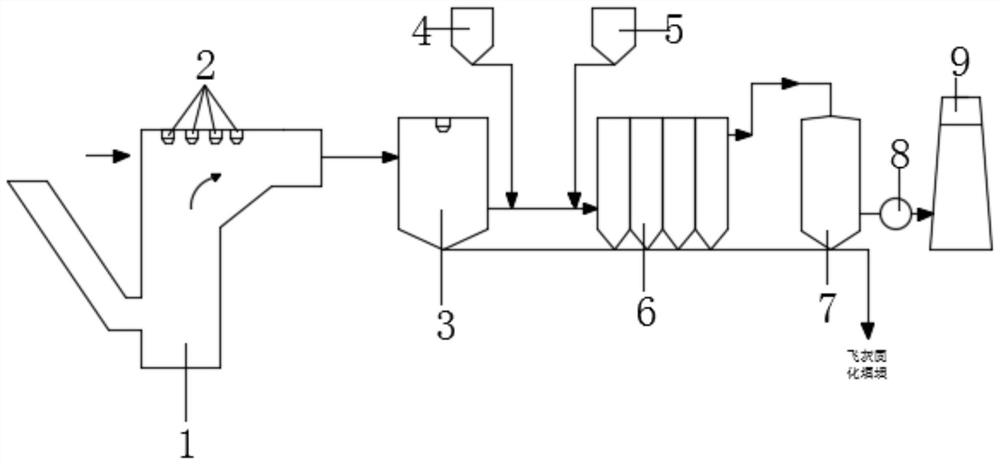

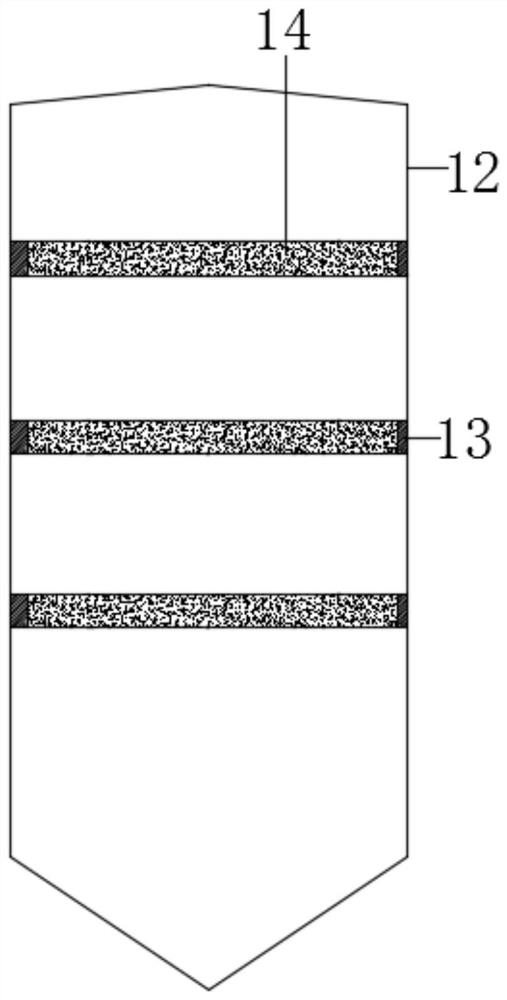

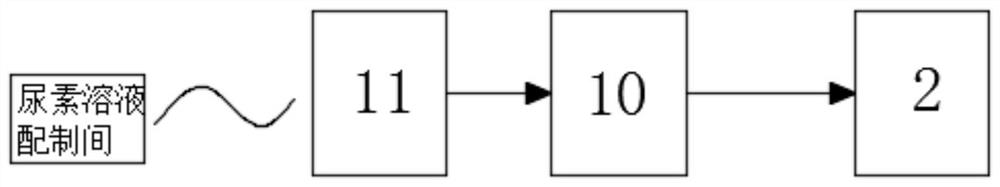

[0029] A flue gas multi-effect bag type dust removal system, reference Figure 1-3 : Including incinerator 1, urea ejection device 2, deacive reaction column 3, sodium carbonate ejection device 4, activated carbon ejection device 5, dust collector 6, SCR denitration device 7, air blower 8 and chimney 9, incinerator 1 The tobacco port is connected to the cigarette port of the deacive reaction column 3, and the smoke port of the deacive reaction column 3 is connected to the cigarette port of the dust collector 6, and the smoke outlet of the deacive reactive tower 3 is located At the bottom, the smoke port of the dust collector 6 is in communication with the inducing port of the SCR denitration apparatus 7, and the smoke port of the SCR denitration device 7 communicates with the air blower 8, the outlet end of the air blower 8 is connected to the chimney 9. , The reactive carbon ejection apparatus 5 and the sodium hydrogencarbonate injection device 4, the sodium hydro...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap