Rubber tube cross section cleaning device and process

A cleaning device and cross-section technology, applied in the direction of tubular objects, metal processing, household appliances, etc., can solve the problems of low degree of automation, inconvenient coil replacement, etc., and achieve the effect of saving money, compact structure, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

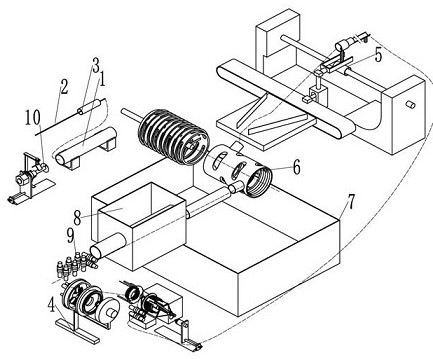

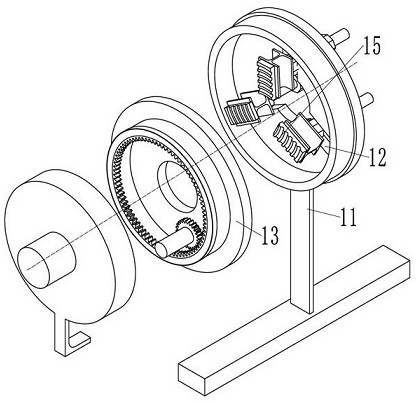

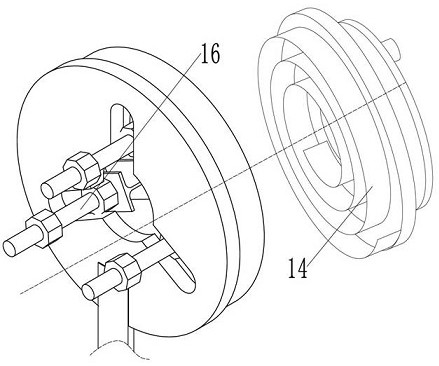

[0032] Such as Figure 1-6 As shown, the rubber hose freezer of this embodiment is used to freeze the rubber hose piece 1 before the winding wire 2 is set; it includes

[0033] The feeding component 4 is used for feeding and outputting the hose piece 1 coiled in the previous process;

[0034] The guide assembly 5 is used for continuously outputting the coiled rubber hose 1 in a straight line;

[0035] The first freezing device 6 includes a first freezing box 7 for precooling the rubber hose 1 to a set temperature;

[0036] The second freezing device 8 is used to freeze the precooled cold rubber pipe fitting 1 in a straightened state;

[0037] The guide conveying roller set 9 is used for conveying the straightened and frozen cold glue pipe 1 between processes.

[0038] The freezer also includes

[0039] Heating sleeve 3, the inner hole of which is used to pass through winding wire 2 and heat;

[0040] The section trimming device 10 is used for trimming and cutting the end ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap