Electric appliance cabinet capable of preventing hot-line work

A technology for live work and electrical cabinets, applied in electrical equipment shells/cabinets/drawers, electrical components, cabinets/boxes/drawer parts, etc. , the effect of device function recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

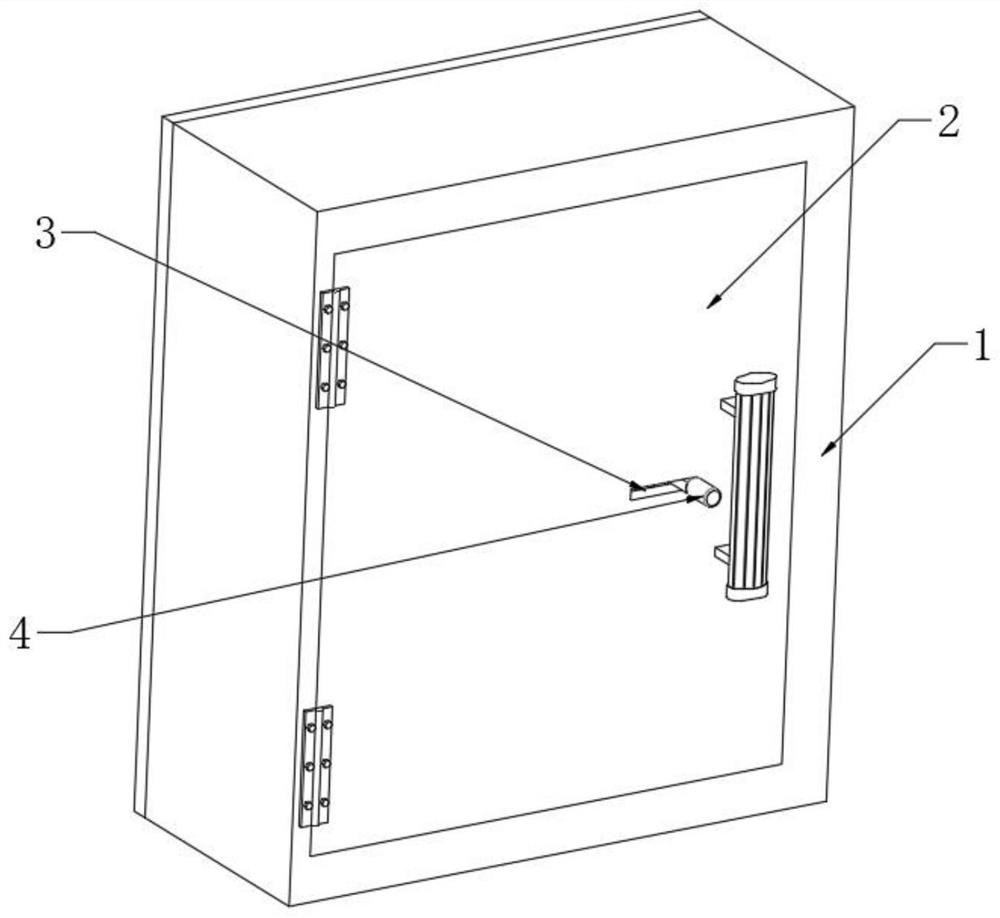

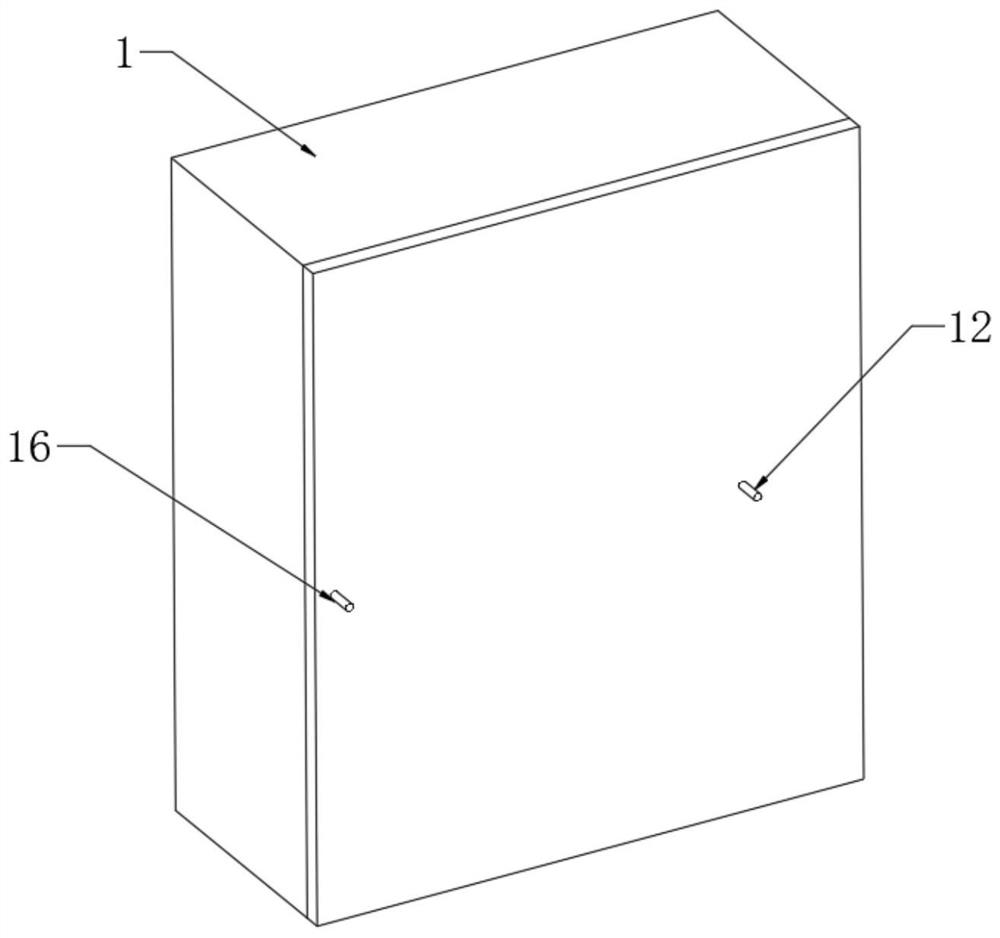

[0023] refer to Figure 1-5 , an electrical cabinet for preventing live work, including a cabinet body 1 and electrical components 11, the front of the cabinet body 1 is hinged to a cabinet door 2, and the inner wall of the cabinet door 2 is fixedly provided with a locking member 10, and the electrical components 11 are installed on Inside the cabinet 1, the electrical components 11 are provided with a positive lead 12 and a negative lead 13, the positive lead 12 runs through the rear side wall of the cabinet 1 and is connected to the mains, and the other end of the negative lead 13 is fixedly connected to a conductive spring 19, The inner rear side wall of the cabinet body 1 is provided with a chute 14, and an iron slider 17 is slidably connected to the chute 14, and one side wall of the iron slider 17 is fixedly connected with an iron clip 18, and The clip 18 is fixedly connected with the other end of the conductive spring 19. The outer side of the conductive spring 19 is co...

Embodiment 2

[0027] refer to Figure 4-5 The difference between this embodiment and Embodiment 1 is that an iron core 20 is fixedly connected to the inner wall of the cabinet body 1, and the iron core 20 is located inside the conductive spring 19, and one end of the iron core 20 close to the iron slider 17 is fixedly connected with a Rubber pad22.

[0028] In long-term use, if the conductive spring 19 is damaged, the conductive spring 19 will stretch under the energized state. At this time, the iron core 20 and the conductive spring 19 form an electromagnet, which attracts the iron slider 17 by magnetic force, so that the iron slider 17 Offset with the rubber pad 22, even if the conductive spring 19 is damaged, the cabinet door 2 can only be opened when the electrical element 11 is powered off, increasing the fault tolerance of the equipment.

Embodiment 3

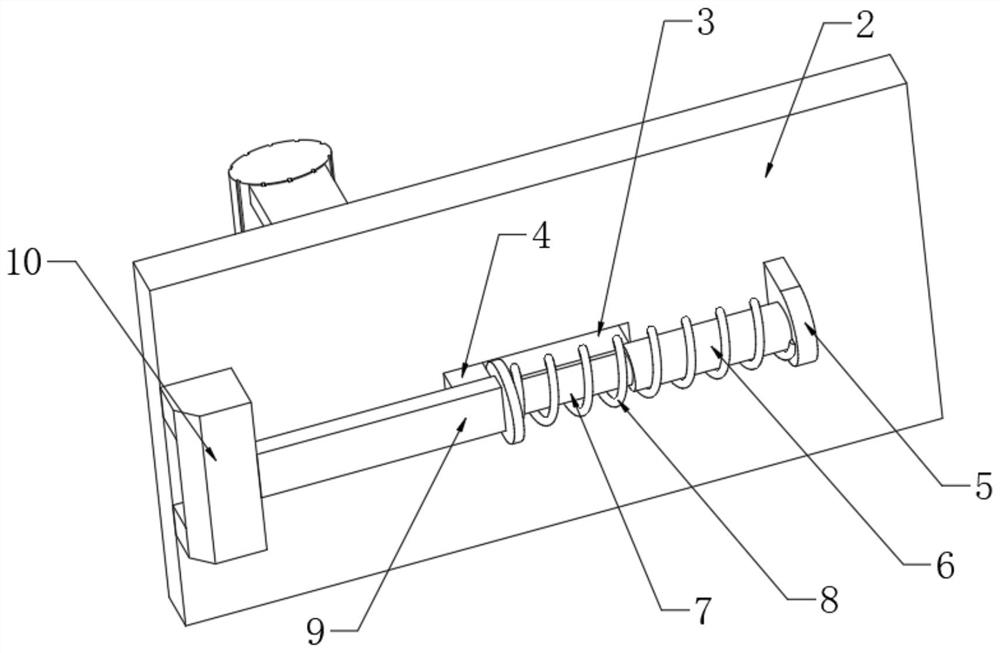

[0030] refer to image 3 The difference between this embodiment and Embodiment 1 is that: the side wall of the cabinet door 2 is provided with a through hole 3, the inner wall of the cabinet door 2 is fixedly connected with a fixed block 5, and one side wall of the fixed block 5 is fixedly connected with a sleeve The other end of the pipe 6 and the casing 6 is slidably inserted with a sliding rod 7, the other end of the sliding rod 7 is fixedly connected with a connecting rod 9, and the other end of the connecting rod 9 is fixedly connected with a locking member 10, and the outer sleeve of the casing 6 A return spring 8 is provided, and the two ends of the return spring 8 are respectively fixedly connected with the fixed block 5 and the connecting rod 9, and the side wall of the connecting rod 9 close to the through hole 3 is fixedly connected with the moving block 4, and the moving block 4 runs through the through hole 3 .

[0031] Under special conditions, if live maintenan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com