Electric wire anti-bird-nesting mechanism based on pressure bar structure

一种电线、压杆的技术,应用在电线防鸟筑巢机构领域,能够解决危险系数高、人工清除难度大等问题,达到结构可靠、防止鸟类筑巢、强实用性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

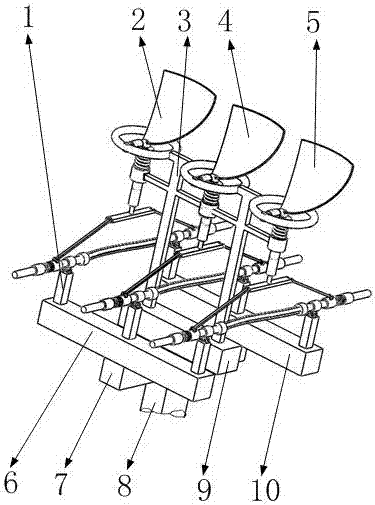

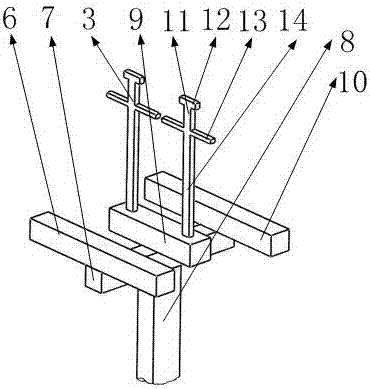

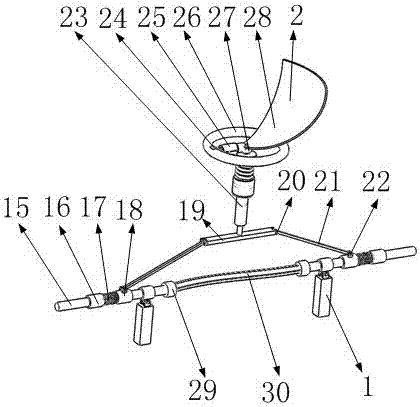

[0029] Such as figure 1 , 3 , 4, it includes the power line support 1, the first power line 2, the second power line 4, the third power line 5, the first support beam 6, the cross beam 7, the pillar 8, the second support beam 9, the third The support beam 10, the first support frame 3, the second support frame 11, and the wires 15, wherein the cross beam 7 is installed at the upper end of the pillar 8, and the first support beam 6, which is perpendicular to it, is installed on the top of the cross beam 7 from one end to the other end. The second support beam 9 and the third support beam 10, the cross beam 7 is used to support the first support beam 6, the second support beam 9 and the third support beam 10, the first support beam 6 and the third support beam 10 each have three A power line support 1 is installed equidistantly, and the first power line 2, the second power line 4 and the 3 groups of the power line supports 1 corresponding to the first support beam 6 and the third ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com