High-voltage frequency converter with safety protection structure and working method thereof

A high-voltage inverter and safety protection technology, applied in the field of high-voltage inverters, can solve problems such as electric shock and low safety in use, and achieve the effects of improving safety, preventing accidental electric shock, and facilitating handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

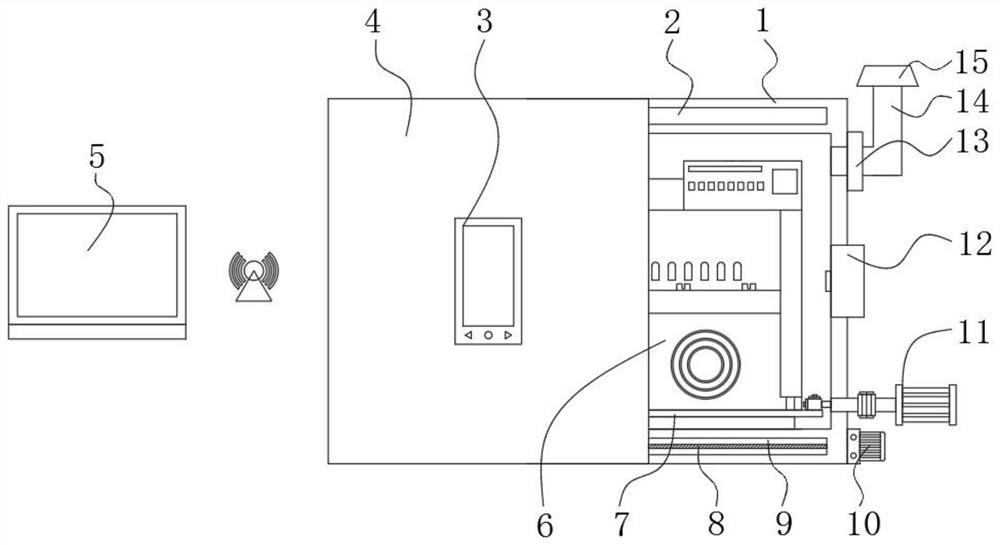

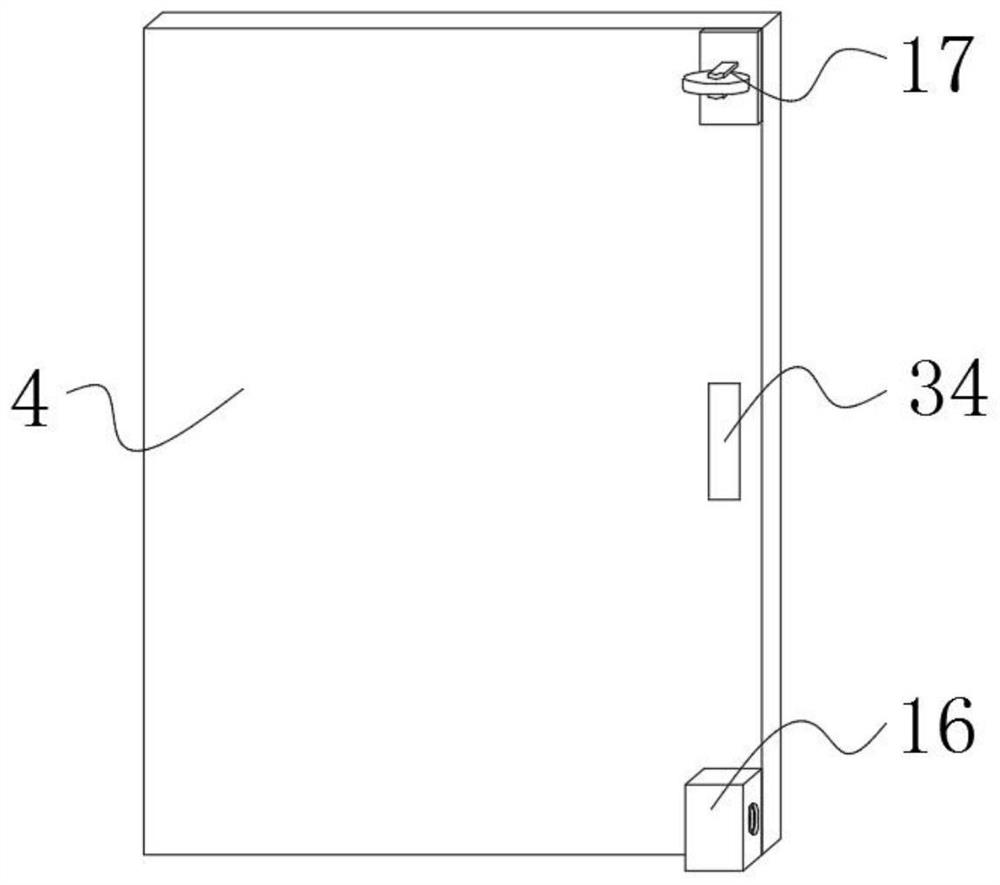

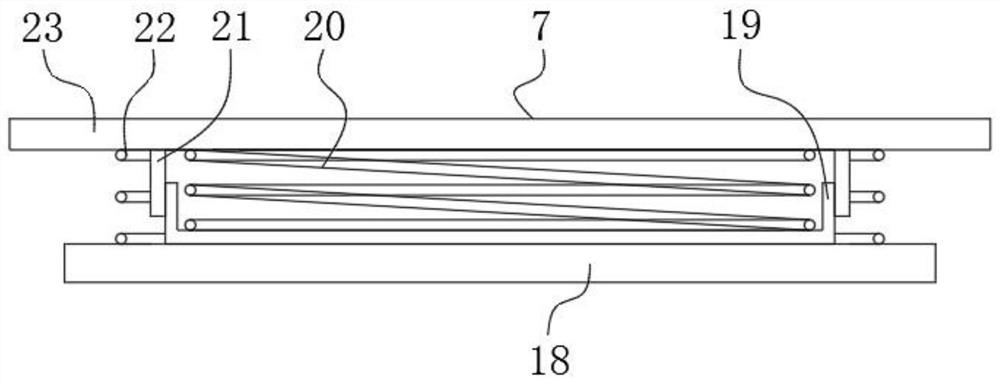

[0030] Attached below Figure 1-6 The specific implementation manner of the present invention will be described in further detail.

[0031] Depend on Figure 1-6 Provided, the present invention provides the following technical solutions: a high-voltage frequency converter with a safety protection structure and its working method, including a protective box 1, a shock absorbing bracket 7 is installed at the center of the bottom inner wall of the protective box 1, and the shock absorbing bracket 7 A high-voltage frequency converter body 6 is installed at the center of the top of the protective box 1, and a glide groove 9 is provided on the bottom side of the protective box 1, and a reciprocating screw rod 8 is connected to the inside of the glide groove 9, and a reciprocating wire rod 8 is installed on the bottom side of the protective box 1. The geared motor 10 driven by the rod 8, the reciprocating screw rod 8 is meshed with a slider 16 that slides inside the sliding groove 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com