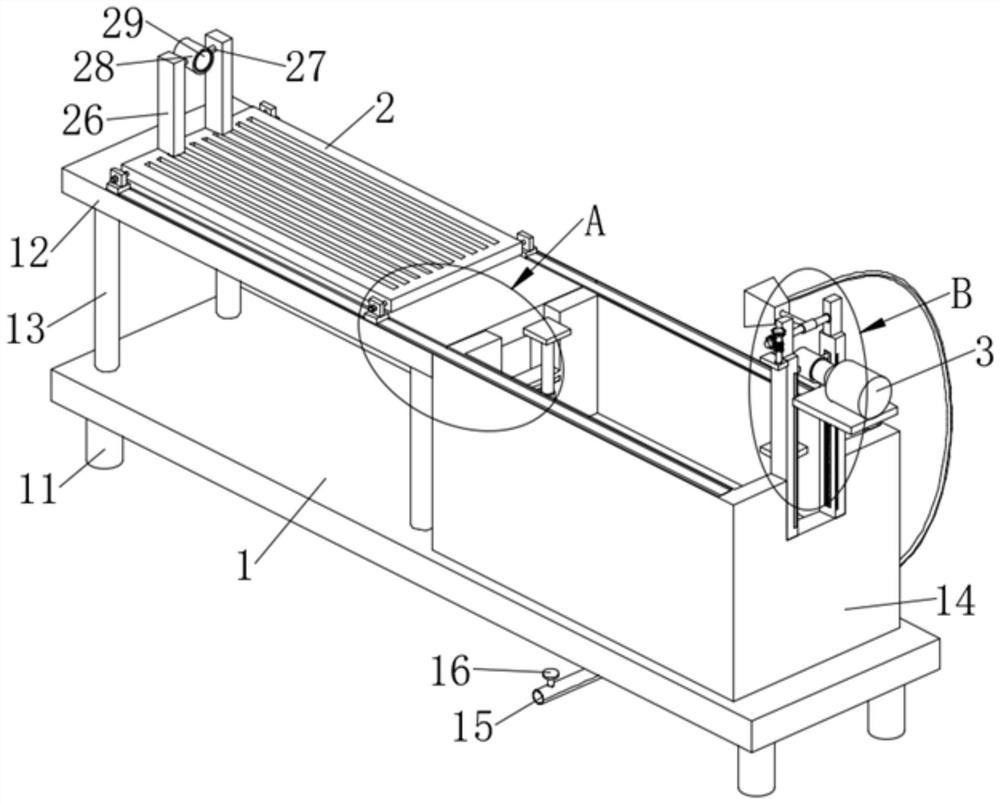

A steam turbine rotor descaling box and descaling method thereof

A technology for steam turbine rotors and casings, applied in separation methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of wasting labor time, inconvenient cleaning and descaling of steam turbine rotors, and inconvenient operation, etc. Improve the efficiency of cleaning and descaling, facilitate cleaning and descaling operations, and improve the effect of convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

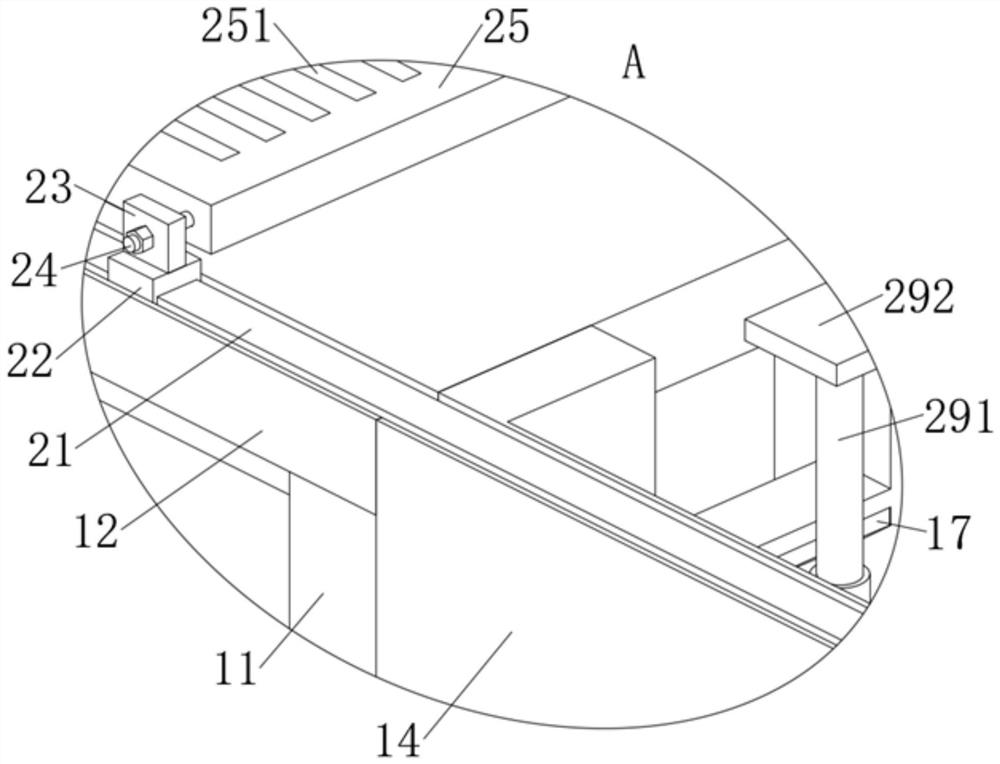

[0043] As an embodiment of the present invention, the surface of the moving plate 25 is evenly distributed with drainage grooves 251.

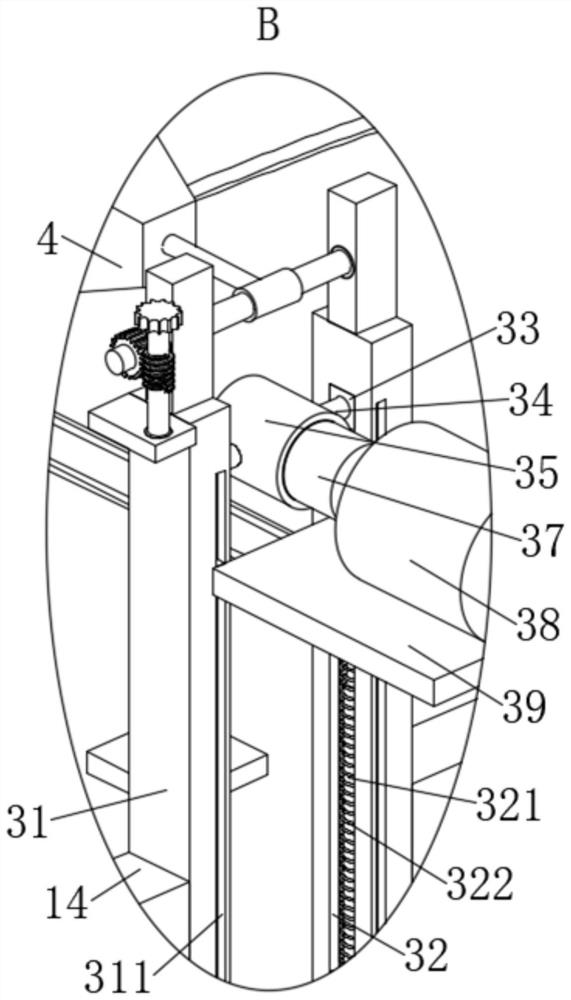

[0044] As an embodiment of the present invention, the clamping and rotating mechanism 3 includes a second vertical plate 31, the second vertical plate 31 and the

[0045] As an embodiment of the present invention, the descaling mechanism 4 includes a third vertical plate 41, the third vertical plate 41 and the second vertical plate 41.

[0046] As an embodiment of the present invention, the upper end of the worm 44 is fixedly installed with a handle 45, and through the knob handle 45,

[0056] Since the filter plate 54 is provided inside the descaling box 14, the cleaning liquid sprayed out during the operation of the high-pressure spray gun body 49

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com