Overclocking frequency-sweeping anti-scaling electrochemical equipment

An electrochemical and anti-scaling technology, applied in chemical instruments and methods, multi-stage treatment of water/sewage, special treatment targets, etc. The effect of avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

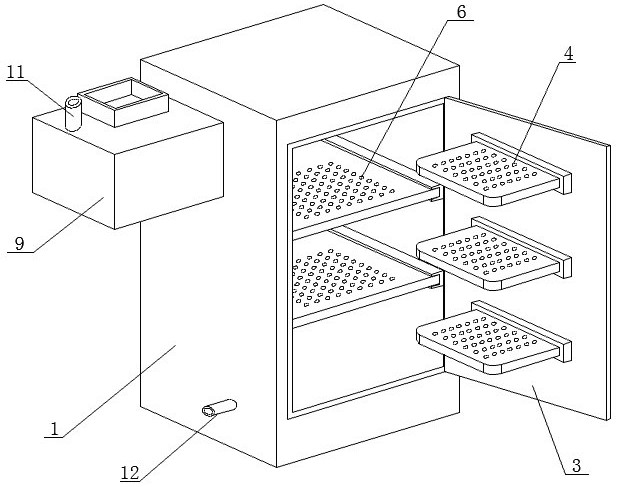

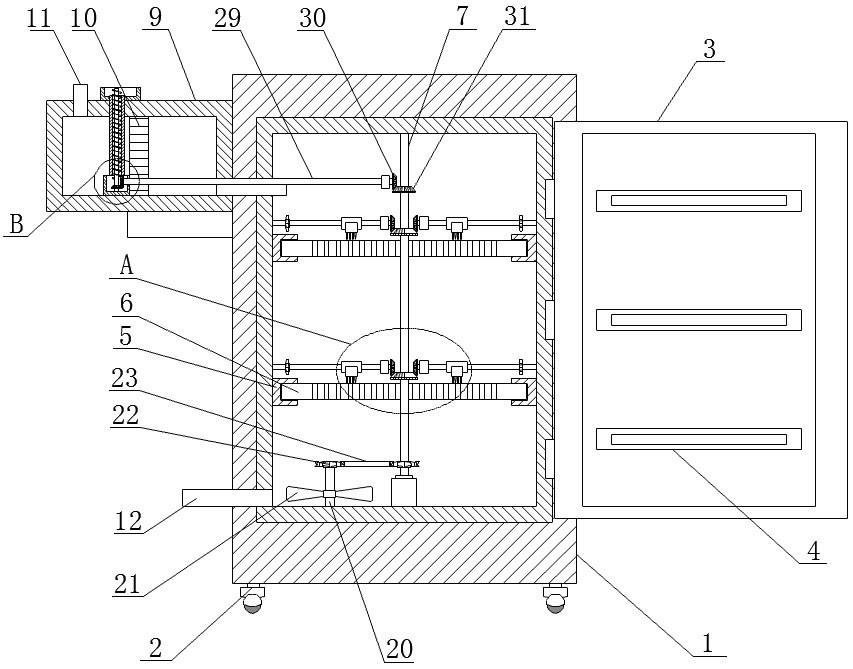

[0027] refer to figure 1 , 2 , 4, 5, 6, ultra-frequency sweep frequency anti-scaling electrochemical equipment, including a treatment box 1, a plurality of rollers 2 are installed on the bottom of the treatment box 1, and a door 3 is hingedly connected to one side of the treatment box 1, and the door 3 A plurality of anode plates 4 are fixedly installed on one side, and a plurality of slide rails 5 are fixedly installed on the inner walls of both sides of the processing box 1, and the same spoiler 6 is slidably arranged in the corresponding two slide rails 5, and the inside of the processing box 1 Vertical rotation is provided with a vertical shaft 7, the vertical shaft 7 is rotatably set on the spoiler 6, the bottom of the vertical shaft 7 is fixedly connected with a motor, the motor is installed on the bottom inner wall of the processing box 1, and the vertical shaft 7 is provided with a linkage Mechanism, positioning slide bar 8 is rotatably connected to the inner walls of...

Embodiment 2

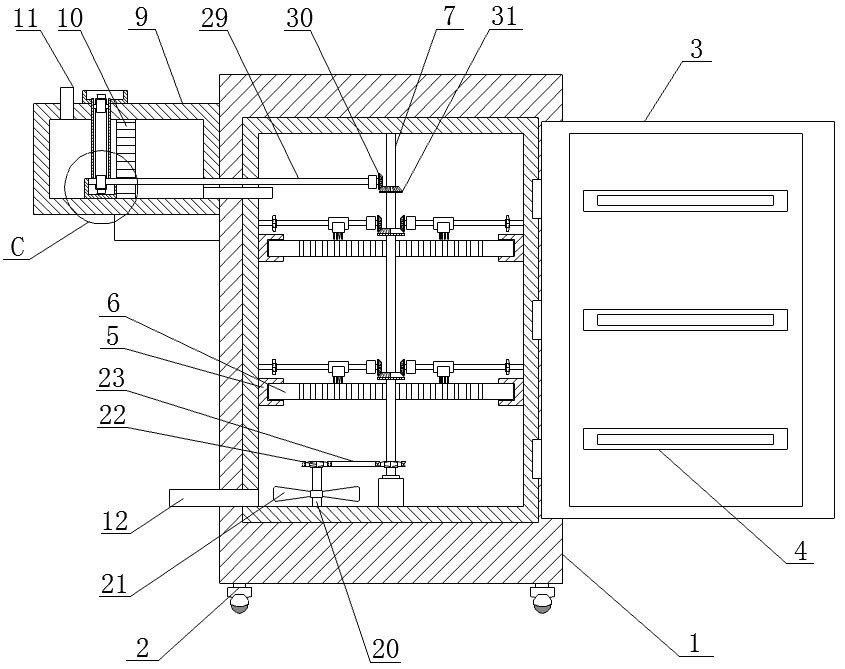

[0037] refer to image 3 , 7 The difference from Embodiment 1 is that one end of the connecting rod 29 extends into the sand tank 24 and is fixedly set with a roller 32, and the top of the conveying sleeve 26 is also provided with a roller 32, and the two rollers 32 are connected with the same The conveyor belt 33 is provided with a plurality of scrapers 34 .

[0038] Working principle, when in use, the sewage is first input into the filter box 9 through the water inlet pipe 11, and the sewage can be preliminarily filtered through the filter screen 10 in the filter box 9, and when the filtered sewage enters the treatment box 1, it is connected to Through the power supply of the anode plate 4, and start the motor, the vertical shaft 7 can be rotated by the motor, and the two first bevel gears 15 can be alternately rotated by the half bevel gear 16 on the vertical shaft 7, so that the two screw rods 13 can be alternately reversed. to rotate, and by positioning the sliding rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com