Hand pressing type atomizing pump

A spray pump and hand pressure technology, applied in the field of spray parts, can solve the problems of insufficient pressure, strong spray force, and inability to atomize the liquid, and achieve the effects of simple structure, moderate spray force, and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

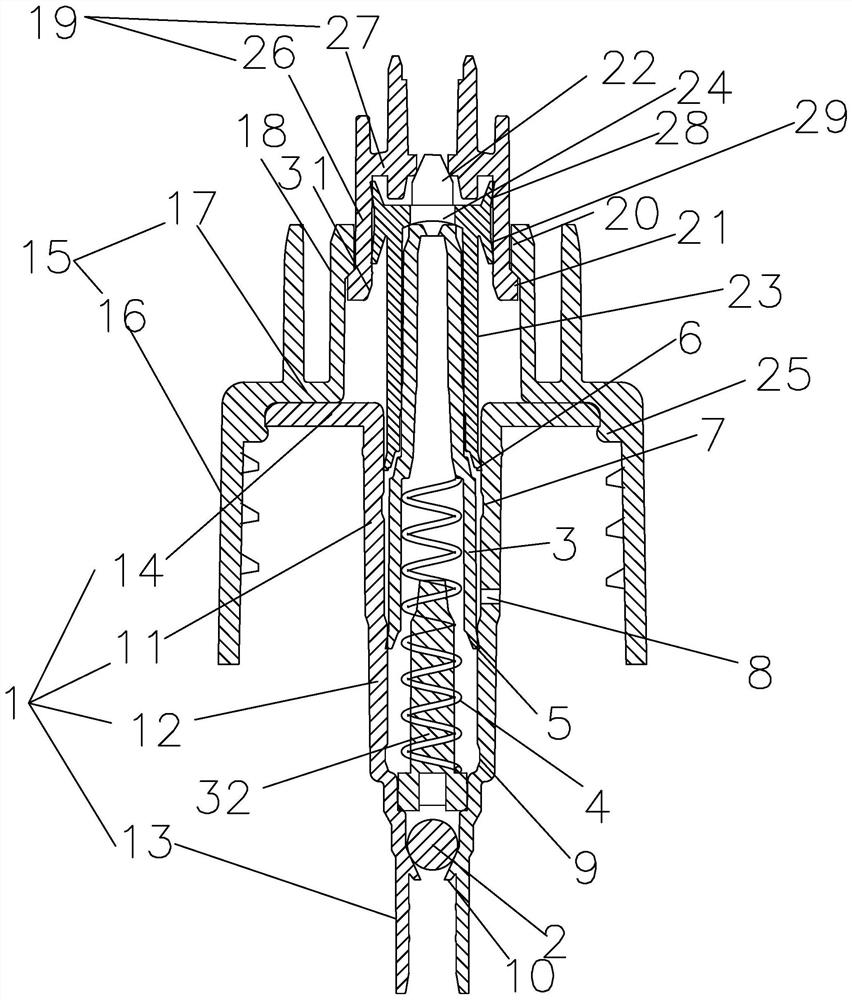

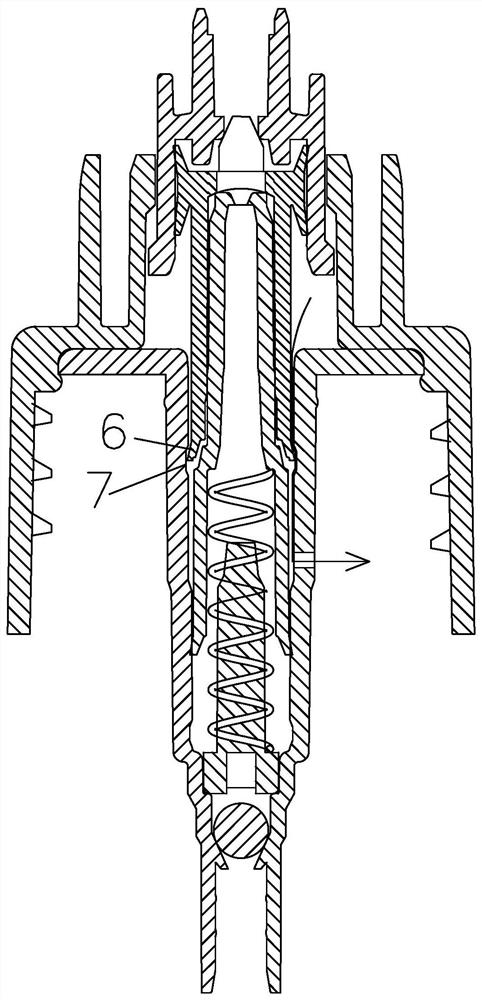

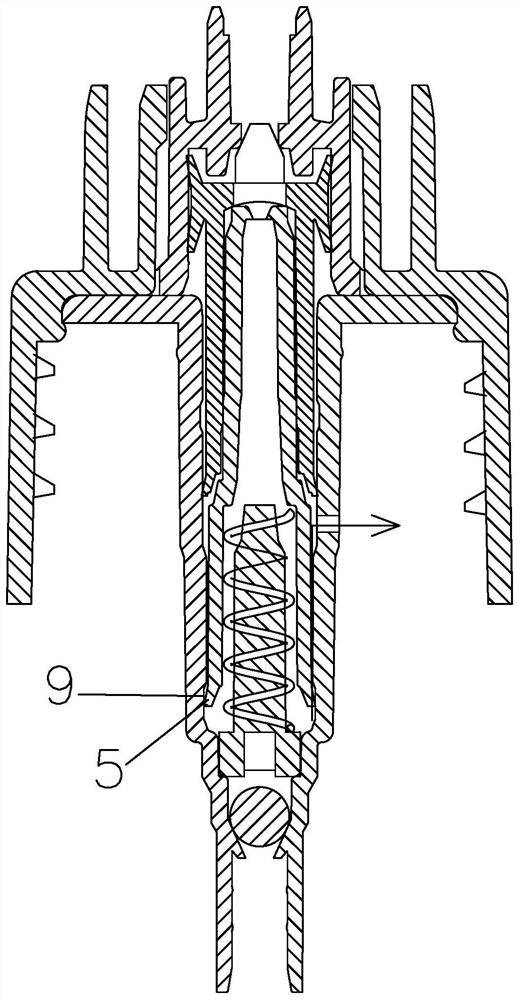

[0021] see Figure 1 to Figure 3 , a hand-operated spray pump, comprising a pump body 1, a sealing ring 10 located at the bottom of the pump body 1, a sealing ball 2 located at the bottom of the pump body 1, the sealing ball 2 is located on the upper side of the sealing ring 10, and an insertion The lower piston 3 on the upper end of the pump body 1, the upper piston 23 sleeved on the upper end of the lower piston 3, the spring 4 located in the pump body 1 for driving the lower piston 3 to move away from the pump body 1, the inner wall of the upper piston 23 is located On one conical surface, the outer wall of the lower piston 3 is located on the other conical surface, and the lower piston 3 is in interference fit with the upper piston 23; the lower piston 3 is provided with a spring seat 32, and the lower end of the spring seat 32 is connected to the suction The upper end of the liquid section 13, the upper end of the spring 4 abuts against the lower piston 3, the spring 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com