Nail polish removing cream

A technology of nail polish remover and acetone nail polish remover, applied in the field of nail polish remover, can solve problems such as pungent nose, dull and dry nail surface, and achieve the effect of safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

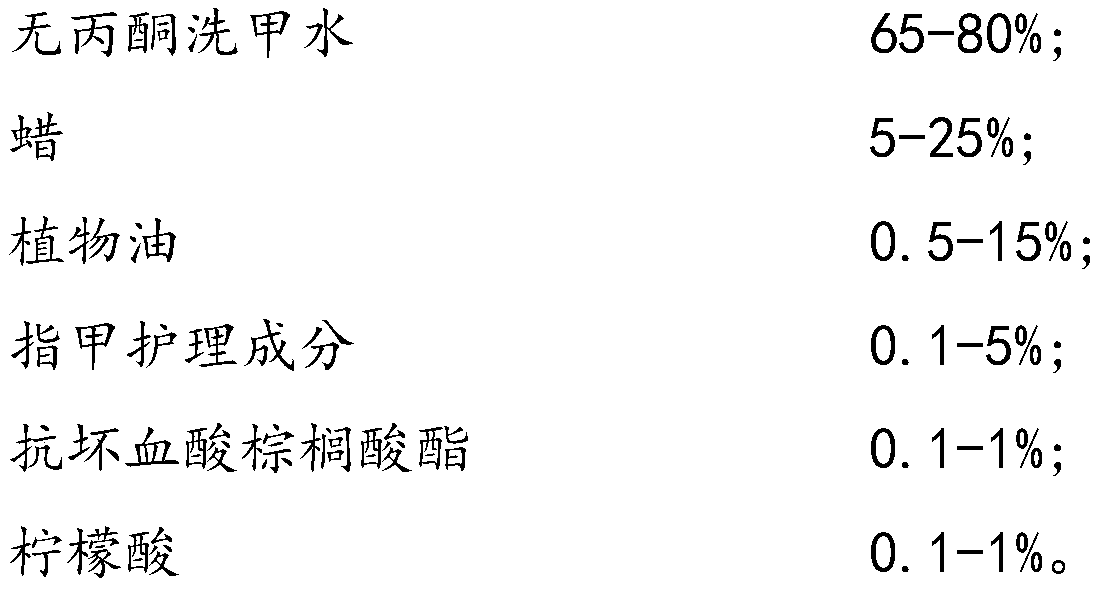

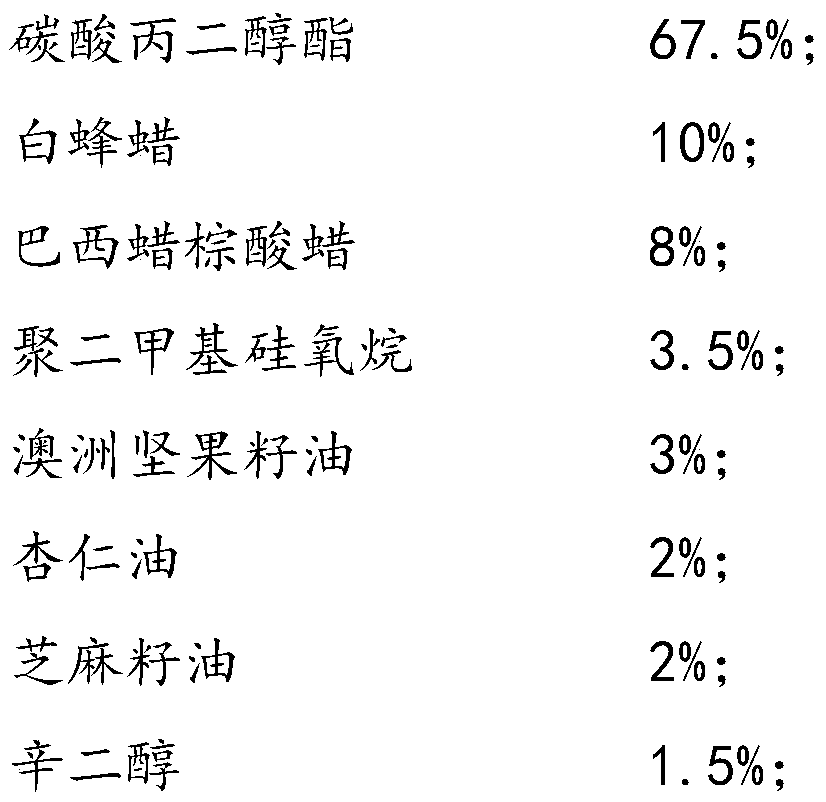

[0035] Product ingredients:

[0036] Propylene Carbonate 67.5%, White Beeswax 10%, Brazilian Wax Palmitate Wax 8%, Dimethicone 3.5%, Macadamia Nut Seed Oil 3%, Almond Oil 2%, Sesame Seed Oil 2%, Caprylyl Glycol 1.5%, ascorbyl palmitate 1%, citric acid 1%, cetearyl alcohol 0.5%.

[0037] Preparation:

[0038] Step 1: Mix 10 parts of white beeswax, 8 parts of Brazilian wax palmitic acid wax, 3.5 parts of dimethicone, 3 parts of macadamia nut oil, 2 parts of almond oil, 2 parts of sesame seed oil, 1.5 parts of caprylyl glycol , mix slowly and heat to 85°C, stir at 100-200 revolutions per minute for 2 hours.

[0039] Step 2: Stir at a speed of 100-200 revolutions per minute, and naturally cool down to 45°C, and keep warm for 3 hours.

[0040] Step 3: Add 67.5 parts of propylene carbonate, 1 part of ascorbyl palmitate, 1 part of citric acid, and 0.5 part of cetearyl alcohol after 3 hours of heat preservation, and stir for 45 minutes at 100-200 rpm.

[0041] Step four:

[0042]...

Embodiment 2

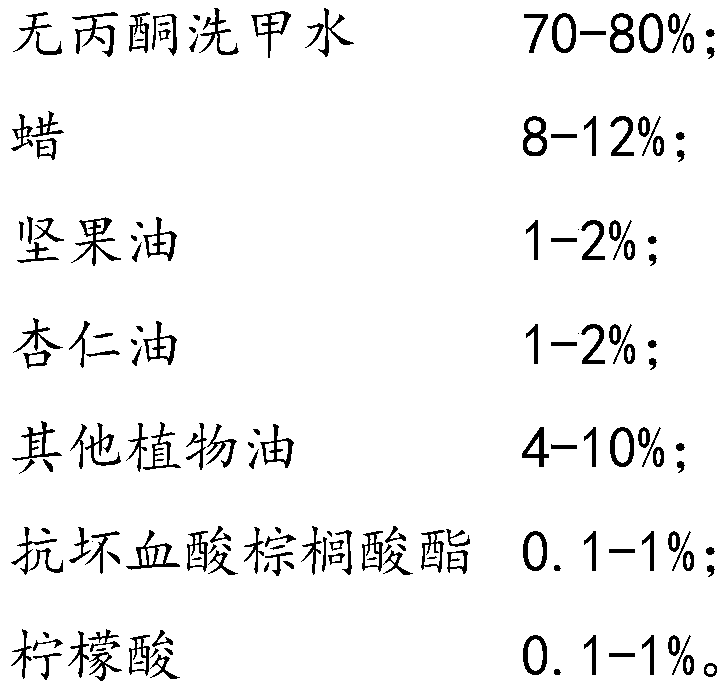

[0049] Product ingredients: acetone-free nail polish remover (can be propylene carbonate or other non-acetone solvents that can be used to remove nails) 76%, wax 10%, vegetable oil 8%, nut oil 2%, almond oil 2%, palmitic acid 1% ester, 1% citric acid, etc.

[0050] Preparation:

[0051] Step 1: Mix 10 parts of wax, 8 parts of vegetable oil, 2 parts of nut oil, and 2 parts of almond oil, slowly heat to 85°C, and stir at 100-200 rpm for 2 hours;

[0052] Step 2: Stir at a speed of 100-200 rpm, and naturally cool down to 45°C, and keep warm for 3 hours;

[0053] Step 3: After 3 hours of heat preservation, add 76 parts of acetone-free nail polish remover, 1 part of palmitate, and 1 part of citric acid, and stir at 100-200 rpm for 45 minutes;

[0054] Step 4: Cool down to room temperature naturally, and the item becomes a fixed paste, ready to use.

[0055] Instructions:

[0056] Apply an appropriate amount of nail polish remover evenly on the nails, and wipe back and forth sev...

Embodiment 3

[0058] Product ingredients: acetone-free nail polish remover (can be propylene carbonate or other non-acetone solvents that can be used to remove nails) 70%, wax 12%, sesame oil 14%, nut oil 1%, almond oil 1%, vitamin E0 .5%, ascorbyl palmitate 1%, citric acid 0.5%, etc.

[0059] Preparation:

[0060] Step 1: Mix wax, sesame oil, nut oil, almond oil, and vitamin E and heat slowly to 75°C, stirring at 100-200 rpm for 2.5 hours;

[0061] Step 2: Stir at a speed of 100-200 rpm, and naturally cool down to 45°C, and keep warm for 3 hours;

[0062] Step 3: After 3 hours of heat preservation, add acetone-free nail polish remover, ascorbyl palmitate, and citric acid, and stir at 100-200 rpm for 45 minutes;

[0063] Step 4: Cool down to room temperature naturally, and the item becomes a fixed paste, ready to use.

[0064] Instructions:

[0065] Apply an appropriate amount of nail polish remover evenly on the nails, and wipe back and forth several times with a cotton pad to remove t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com