Liquid foundation and preparation method thereof

A liquid foundation and mass percentage technology, which is applied in pharmaceutical formulations, cosmetic preparations, cosmetic preparations, etc., can solve the problems of drug effects colliding and canceling each other.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

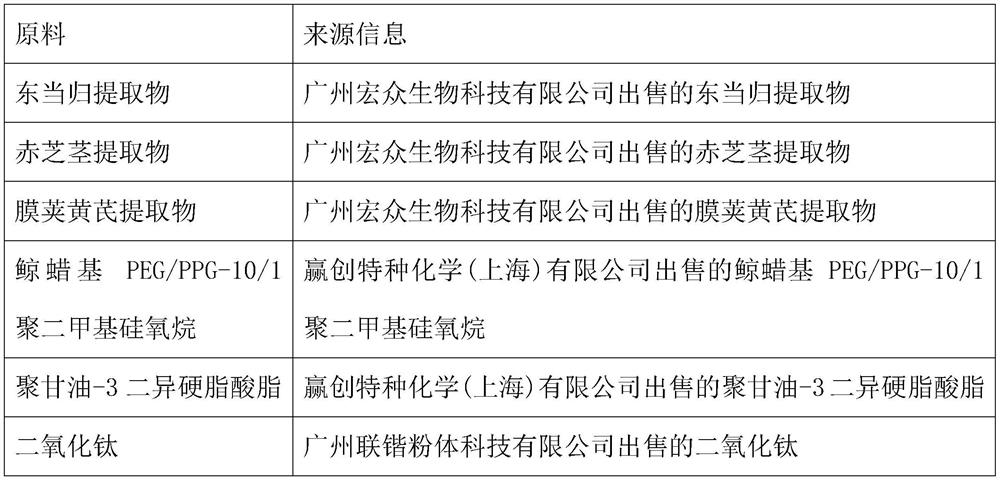

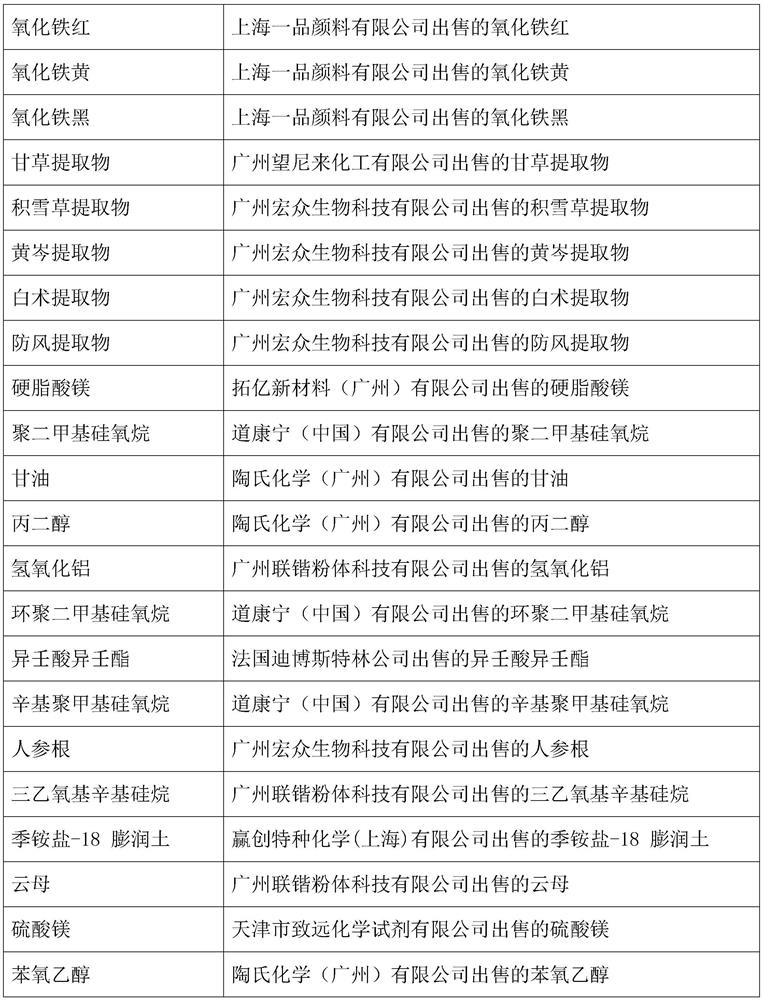

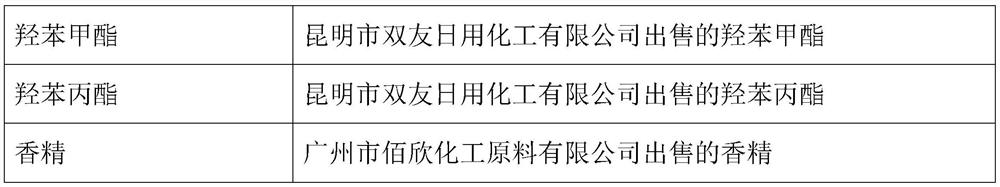

[0070] Embodiment 1-3: a kind of liquid foundation, comprises following component:

[0071] Dong Angelica Extract, Chizhi Stem Extract, Astragalus membranaceus Extract, Emulsifier, Colorant, Solvent. The emulsifier is a compound of cetyl PEG / PPG-10 / 1 polydimethylsiloxane and polyglyceryl-3 diisostearate; the coloring agent is titanium dioxide, iron oxide red, iron oxide yellow, oxidation The compound of iron black; the solvent is water. Embodiment 1-5, the input amount (unit Kg) of each component sees Table 2 for details

[0072] Table 2

[0073]

Embodiment 1-5

[0074] The preparation method of embodiment 1-5 liquid foundation comprises the following steps:

[0075] Step 1), raw material pretreatment;

[0076] Step 1-1), adding water into the first stirred tank with a rotating speed of 60r / min, then heating to 85°C while stirring, and first keeping the temperature at 85°C for 10 minutes to obtain the first processed product;

[0077] Step 1-2), select cetyl PEG / PPG-10 / 1 polydimethylsiloxane, polyglycerol-3 diisostearate, titanium dioxide, iron oxide red, oxidized Iron yellow and iron oxide black are put into the second stirred tank at a speed of 120r / min, then heated to 85°C while stirring, then kept at 85°C for 10 minutes, and discharged into the container to obtain the second pretreated product;

[0078] Step 2), put the second pretreated substance into the first treated substance at a rotation speed of 60 r / min, stir for 3 minutes, stir evenly, and keep the temperature at 85° C. for 30 minutes to obtain the second treated substanc...

Embodiment 6

[0082] Compared with Example 2, the only difference is: in step 1-1), the water is heated to 88°C.

[0083] Step 1-2), then heated to 88°C while stirring, and then kept at 85°C for 12 minutes. In step 2), heat preservation at a temperature of 88° C. for 32 minutes. In step 3), the temperature of the second treated object was lowered to 47°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com