A kind of anti-chapping skin care product and its preparation

A technology of skin care products and stem extracts, which is applied in the field of anti-chapping skin care products and its preparation, and can solve the problems of easy repetition and poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

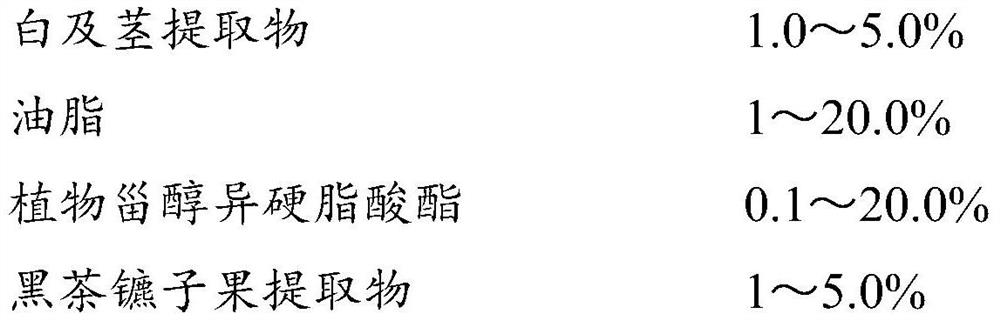

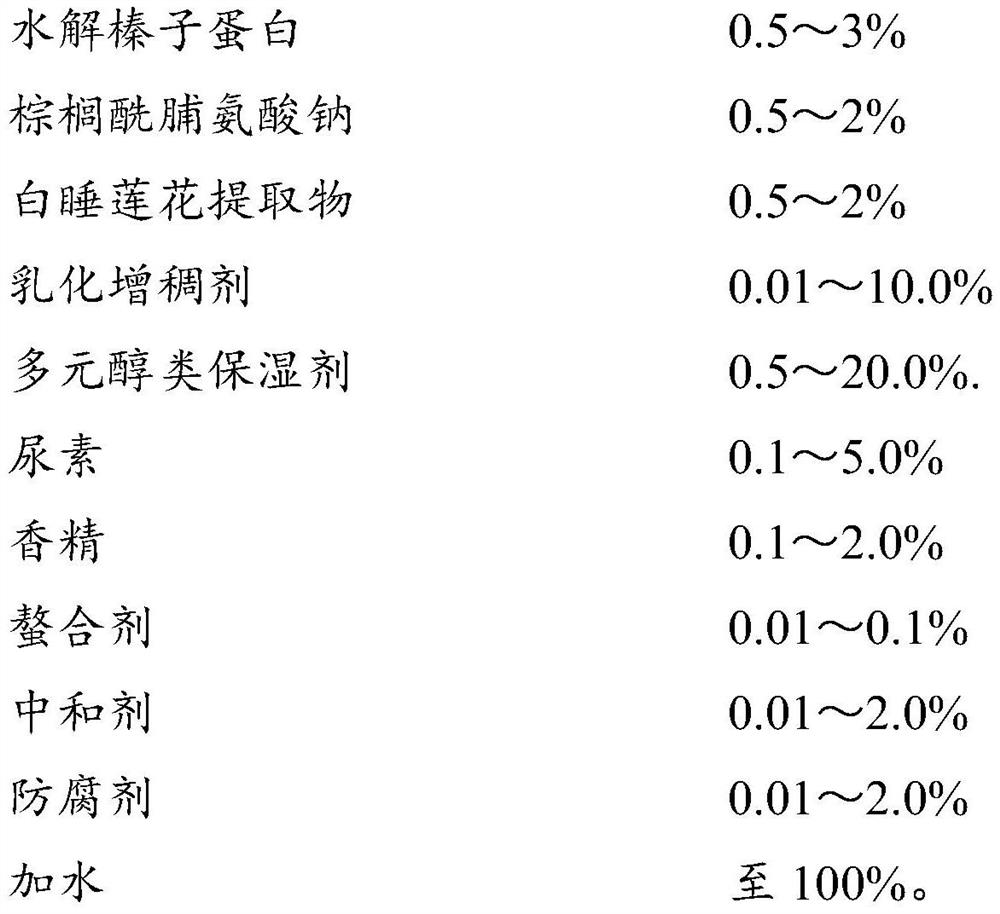

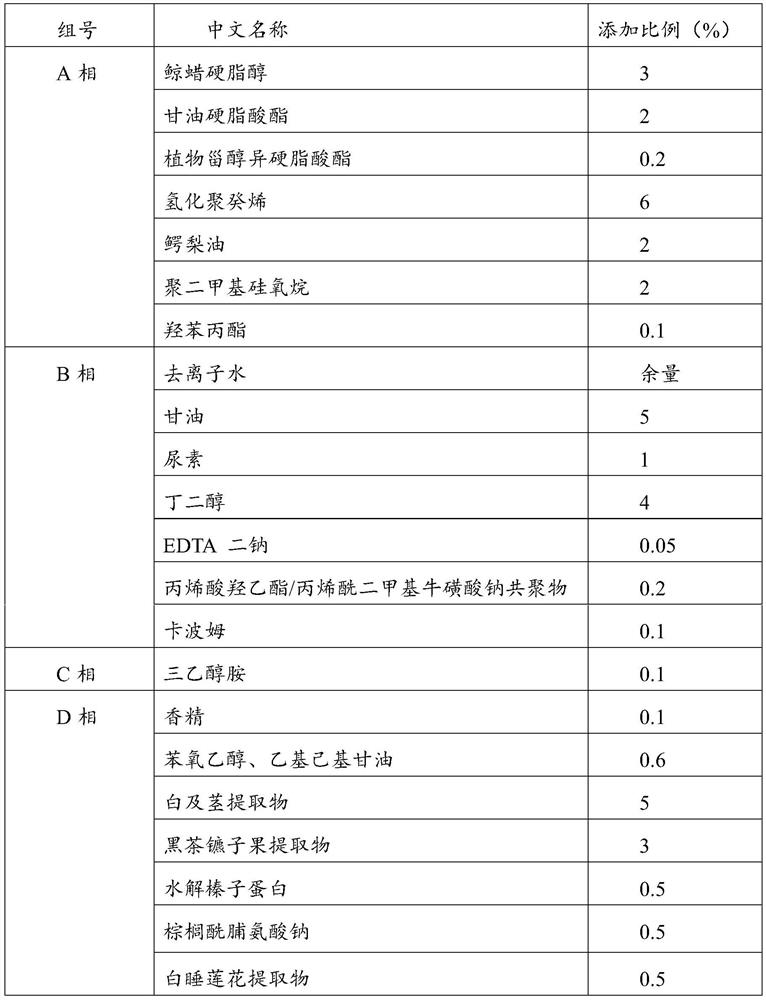

[0036] An anti-chapping skin care lotion, comprising the components shown in Table 1 in weight percentage.

[0037] The raw material sub-table of the skin care lotion of the white stem extract contained in table 1

[0038]

[0039] The production process is as follows:

[0040] 1. Weigh the raw materials of component A according to the ratio in Table 1, put component A into a suitable container, heat to 80-85°C, stir until completely dissolved, and use it as the oil phase.

[0041] 2. Weigh the raw materials of component B according to the ratio in Table 1, put component B into a suitable container, heat to 80-85°C, stir until completely dissolved, and use it as the water phase.

[0042] 3. Turn on the stirring speed at 20r / min, slowly add the oil phase of component A into the heated water phase of component B at a stirring speed of 40r / min, turn on the homogenizer, and homogenize for 3 minutes. The speed is 3000r / min.

[0043] 4. Stir slowly and cool down to 70-60°C, th...

Embodiment 2

[0055] An anti-chapping skin care cream, including the components shown in Table 2 in weight percentage.

[0056] The raw material sub-table of the skin care cream of the white stem extract that table 2 contains.

[0057]

[0058]

[0059] The production process is as follows:

[0060] 1. Weigh the raw material of component A according to the ratio in material table 2, put component A into a suitable container, heat to 80-85°C, stir until completely dissolved, and use it as the oil phase.

[0061] 2. Weigh component B raw materials according to the ratio in material table 2, put component B into a suitable container, heat to 80-85°C, stir until completely dissolved, and use it as the water phase.

[0062] 3. Turn on the stirring speed at 20r / min, slowly add the oil phase of component A into the heated water phase of component B at a stirring speed of 40r / min, turn on the homogenizer, and homogenize for 3 minutes. The speed is 3000r / min.

[0063] 4. Stir slowly and coo...

Embodiment 3

[0067] An anti-chapping lotion, including the components shown in Table 3 in weight percentage.

[0068] Table 3 Raw material sub-list of lotion containing white and stem extract

[0069]

[0070]

[0071] The production process is as follows:

[0072] 1. Weigh the raw materials of component A according to the ratio in material table 3, put component A into a suitable container and heat to 80-85°C, stir until completely dissolved, keep warm for 30min, and then start to cool down.

[0073] 2. Cool to 75-70°C and weigh the raw materials of component B according to the ratio in Table 3, put component B into component A, and stir until completely dissolved.

[0074] 3. Stir and cool down to 45°C, add phase C, solidify when cooled to room temperature, adjust the pH value to 5.0-7.0, pass the inspection, and discharge the material.

[0075] Wherein the extracting method of the Radix Radix Radix Radix Extract is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com