A kind of electric power tube well and its construction technology

A technology for power pipes and pipes, applied in vertical pipes, buildings, building components, etc., can solve problems such as time-consuming, inconvenient, and narrow tube well space, and achieve the effect of reducing the probability of shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present application will be described in further detail below with reference to all the accompanying drawings.

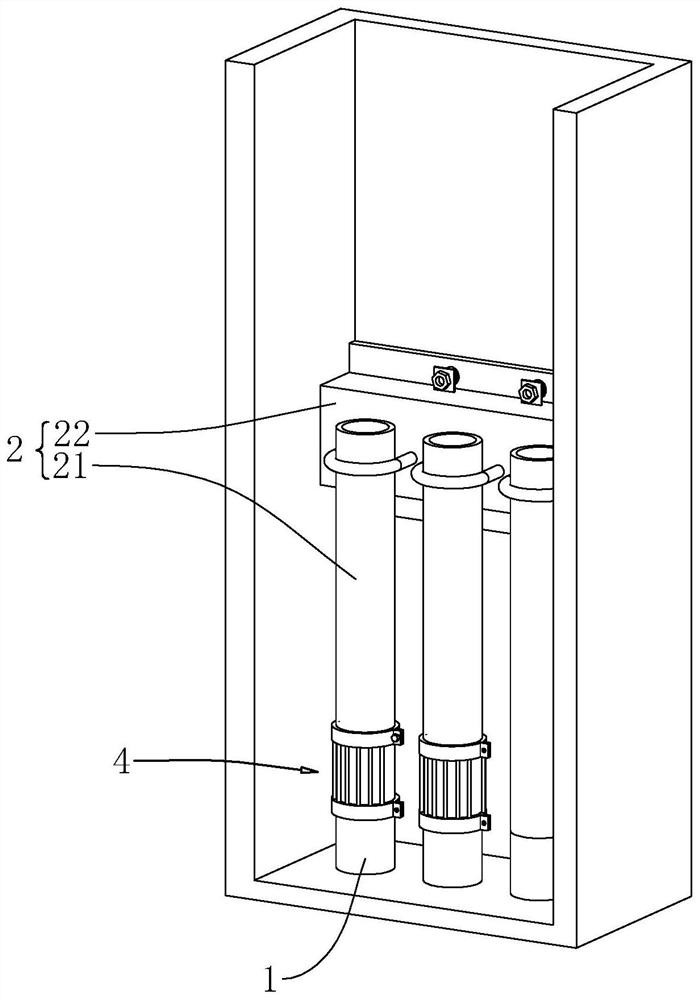

[0038] The embodiment of the present application discloses a power pipe well. refer to figure 1 , including a plurality of pre-embedded pipes 1 and a plurality of modular pipes 2, the number of pre-embedded pipes 1 is at least three, and three pre-embedded pipes 1 are set in this embodiment. The plurality of pre-embedded pipes 1 are arranged at intervals along the linear direction. The embedded pipe 1 is vertically arranged on the ground, and the embedded pipe 1 is used for connecting with the modular pipeline 2 by welding or gluing.

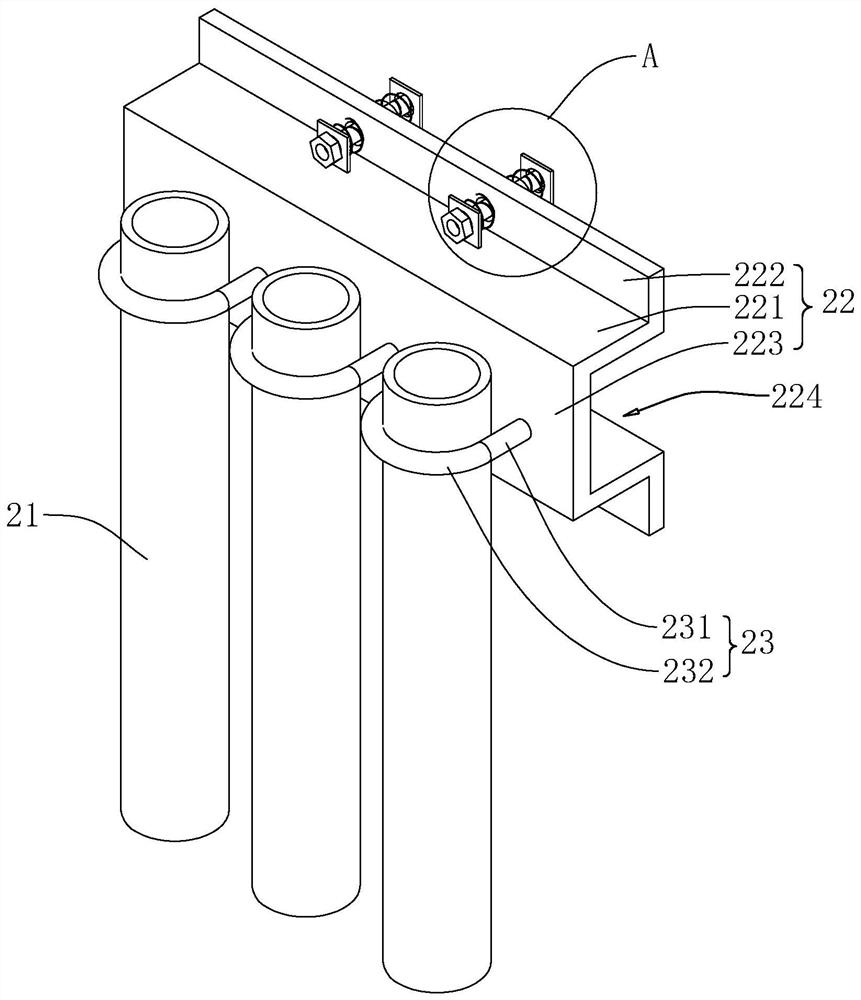

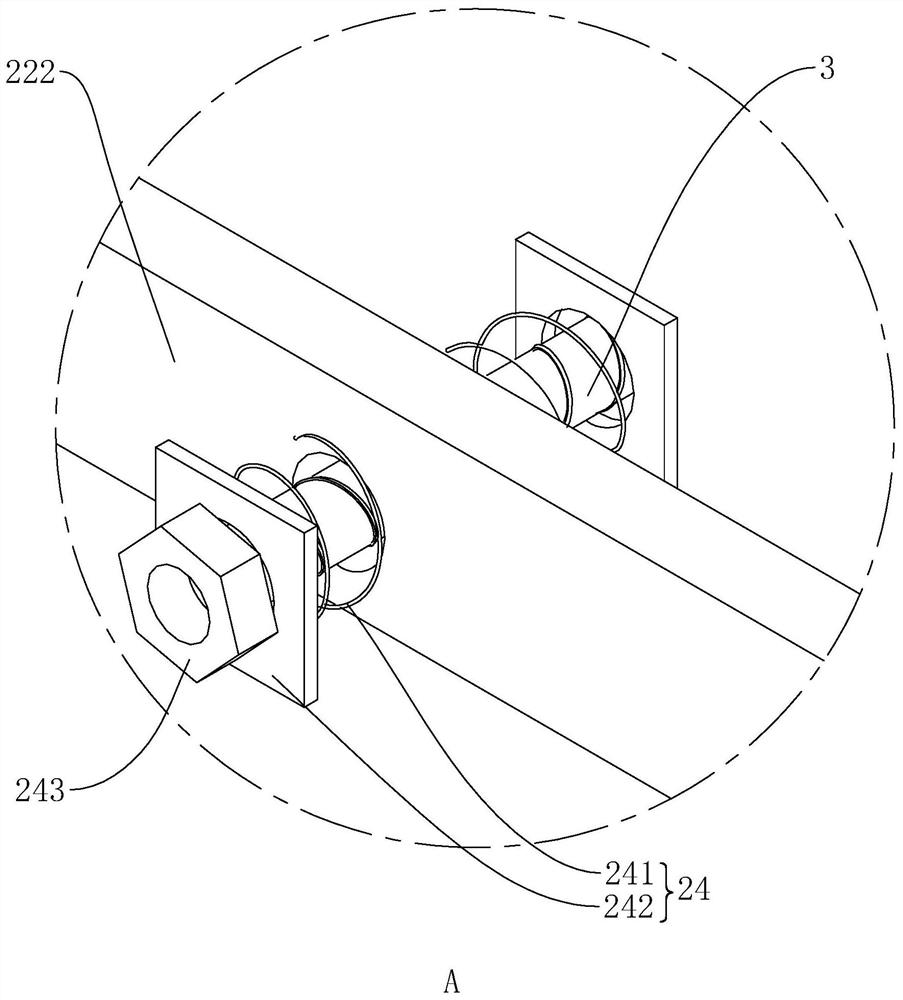

[0039] refer to figure 1 and figure 2 , the modular pipeline 2 includes a plurality of connecting pipes 21 and a base plate 22 , the connecting pipes 21 are arranged vertically, and the number of the connecting pipes 21 is equal to the number of the embedded pipes 1 . The diameter of the connecting pipe 21 is equal to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com