Web-tapped partial combined shear wall-combined connecting beam coupled wall and production method thereof

A technology of combining shear walls and shear walls, applied in the directions of walls, joists, girders, etc., can solve problems such as long periods of time, and achieve the effects of high assembly rate, reduced construction man-hours, and fast construction speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

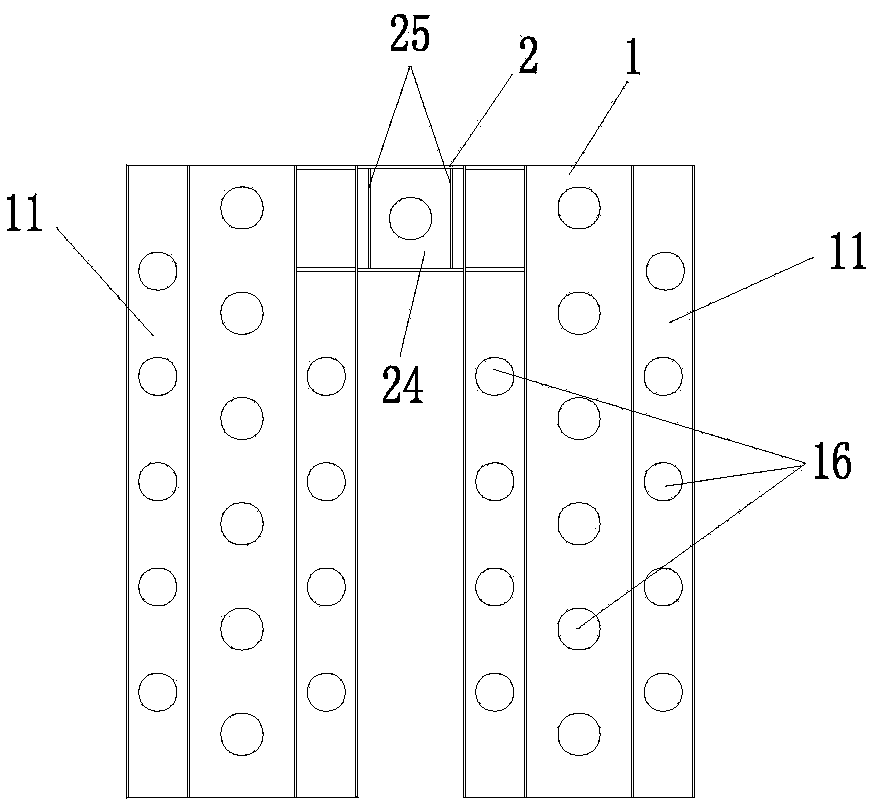

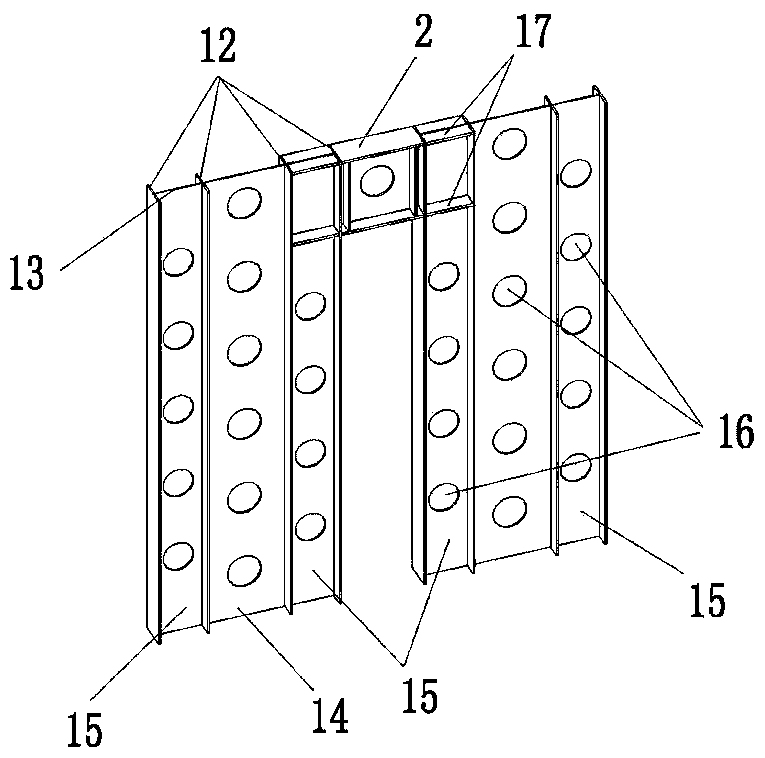

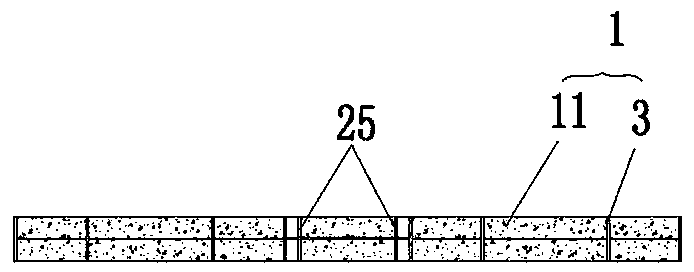

[0034] as attached figure 1 to attach Figure 5 As shown, a composite shear wall with a web opening part of the present application-composite connecting beam and limb wall includes 2 or more than 2 pieces of PEC shear walls 1, and a combined connection for connecting PEC shear walls 1. The beam 2 connects multiple pieces of PEC shear walls 1 piece by piece through the combined connecting beam 2 to form a new type of combined shear wall-combined connecting beam and limb wall.

[0035] The PEC shear wall 1 is composed of an H-shaped steel skeleton 11 formed by connecting a plurality of T-shaped steels in a straight line and concrete 3 filled in the H-shaped steel skeleton 11 .

[0036] The H-shaped steel skeleton 11 includes a web 12 and a wing 13 perpendicular to the web 12. In this embodiment, the H-shaped steel skeleton 11 is formed by connecting three T-shaped steels in a straight line. 13. Divide the H-shaped steel skeleton 11 into a central middle grid 14 and side grids ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com