Pressure-tight wire connection device

A technology of wire connection and pressure-resistant sealing, which is applied in cable inlet sealing devices, cable installation, cable joints, etc., can solve the problems of complex structure of cable sealing components, unsatisfactory sealing effect, use of molds, etc., to achieve structural The effect of simplicity, low cost and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

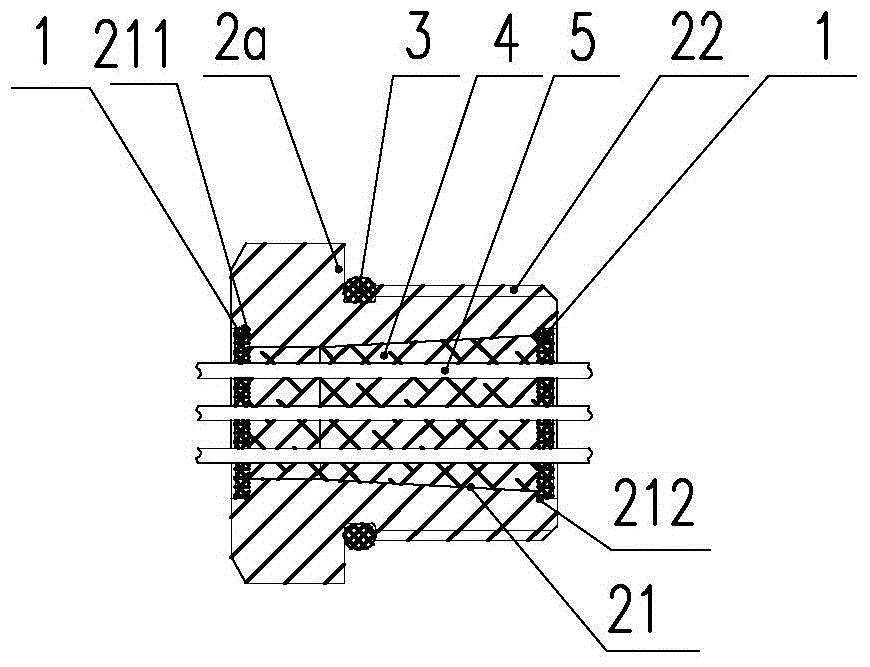

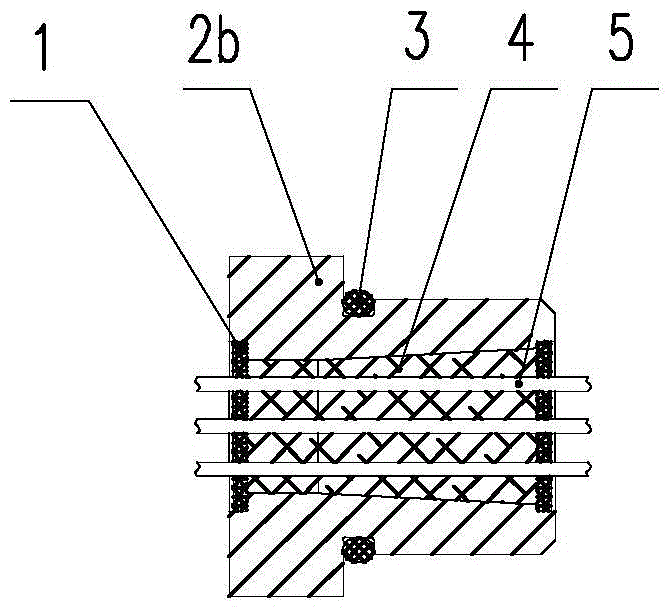

[0035] The pressure-resistant and sealed wire connection device of the present invention in the form of threaded installation:

[0036] Such as Figure 1-1~Figure 1-2 As shown, the pressure-resistant and sealed wire connection device includes a branch line support plate 1, a joint 2, a sealing ring 3, a filling sealant 4, and a wire 5 used to communicate with the inside and outside of the tank;

[0037] The shape of the joint 2 is a cylinder with unequal diameters formed by a hexagonal cross-section at the large end and a circular cross-section at the small end. There is a through hole 21 inside, and steps 211 and 212 are respectively provided at both ends of the through hole. The outer edge of the cylinder at the small end has threads 22;

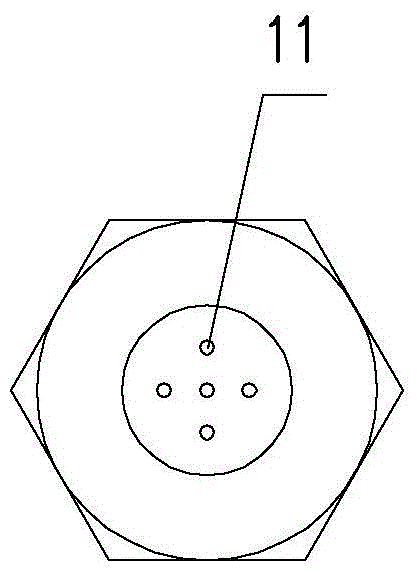

[0038] Five small holes 11 for threading wires 5 are arranged on the branching support plate 1;

[0039] In the assembled state, the two branch line support plates 1 are respectively placed on the steps 211 and 212 at both ends of the thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com