Rotary passive terahertz security inspection equipment and backboard structure thereof

A safety inspection and passive technology, which is applied in measuring devices, material analysis through optical means, optical device exploration, etc., can solve the problems of inability to switch working modes, affect the performance and limitations of passive terahertz safety inspection equipment, and achieve expansion The effect of using the environment range, improving the temperature uniformity, and improving the temperature uniformity and cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

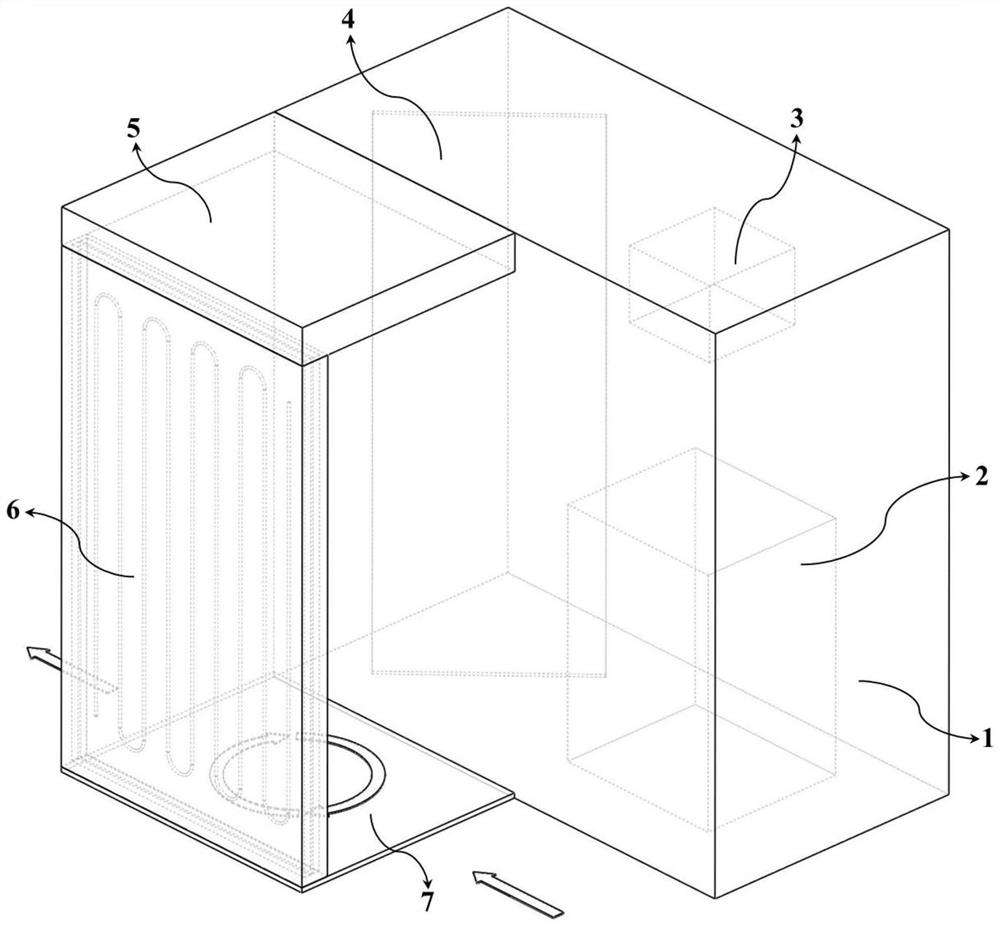

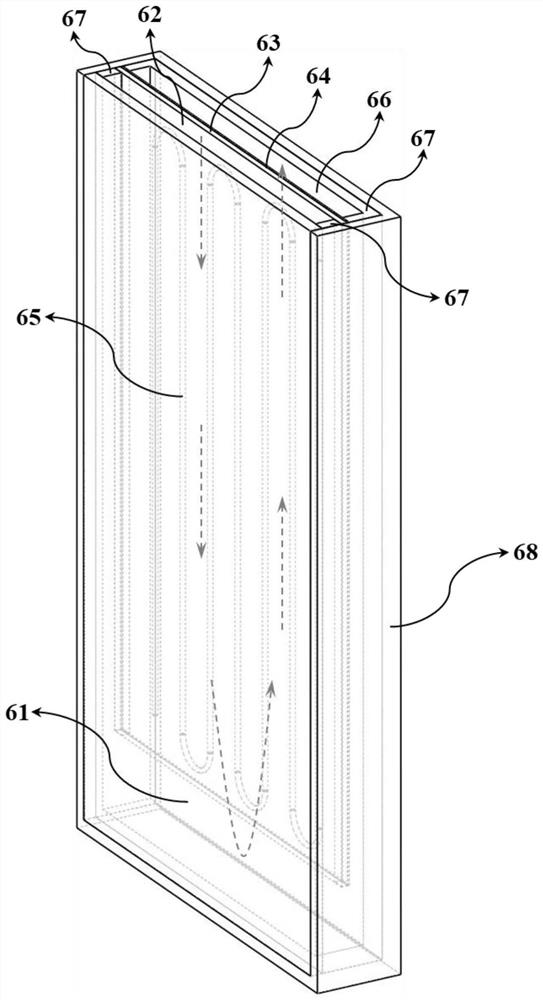

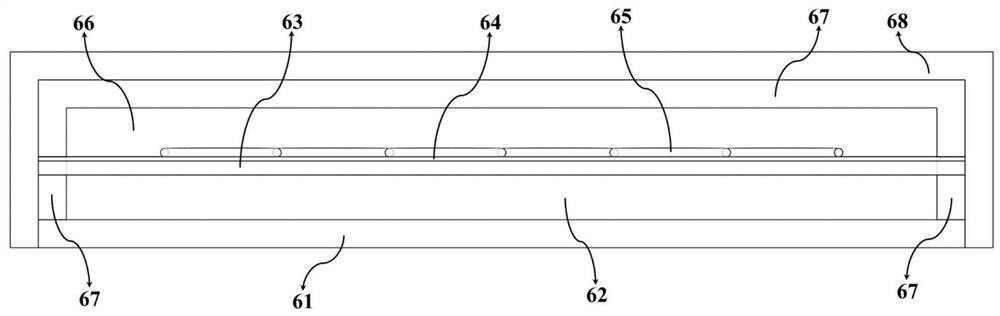

[0037] Such as Figure 1 ~ Figure 3 As shown, the rotating passive terahertz safety inspection equipment includes equipment area 1, terahertz equipment 2, refrigeration equipment 3, reflector 4, top plate 5, back plate 6, and bottom plate 7, and the rotating passive terahertz safety inspection equipment back plate 6 Such as Figure 2~3 As shown, it includes a wave-transparent layer 61, a first wind cavity 62, a wave-absorbing layer 63, a second wind cavity 66, and a structural support layer 68, and a cavity with an open top is formed between the wave-transparent layer 61 and the structural support layer 68. , the wave-absorbing layer 63 separates the cavity into a first wind cavity 62 and a second wind cavity 66 , and the bottom of the first wind cavity 62 communicates with the second wind cavity 66 . The air inlet on the top of the first air chamber 62 of the backplane 6 is connected to the air outlet of the refrigeration equipment 3, and the top air outlet of the second air...

Embodiment 2

[0041] In this embodiment, on the basis of Embodiment 1, the thickness of the first air chamber 62 and the second air chamber 66 are the same, and several elongated deflectors are arranged inside, so as to improve the structural strength and stability between the layers inside the back plate 6. stability, while further improving the uniformity of the low-temperature air on both sides of the wave-absorbing layer 63 and the temperature uniformity of the wave-absorbing layer 63 itself. The wave-absorbing layer 63 is a composite structure composed of terahertz wave-absorbing materials, wooden boards, gypsum, rubber, and carbon, and is firmly installed on the structural support layer 68 through both sides of the wave-absorbing layer 63 and the metal layer 64 .

[0042] In this embodiment, the ambient temperature is 35°C. After the terahertz security inspection equipment works normally for 15 minutes, the temperature on both sides of the working area of the wave-absorbing layer 63 ...

Embodiment 3

[0045] This embodiment is on the basis of embodiment 1, as Figure 4 , Figure 5 As shown, a top plate 5 is set on the terahertz security inspection equipment, and the top plate 5 includes a blowing cavity, a blowing mechanism 53, an air exhausting cavity, an exhausting mechanism 54, and an air duct partition. Separated, the blowing mechanism 53 is arranged in the blowing chamber and communicates with the top of the first air chamber 62 , and the exhaust mechanism 54 is arranged in the exhaust chamber and communicates with the top of the second air chamber 66 .

[0046] An air channel switching mechanism 51 is provided on the air channel partition to separate the blowing cavity and the exhaust cavity from the external air outlet, and the blow cavity and the exhaust cavity are directly connected to form a complete air channel. The air channel switching mechanism 51 is used to switch the blowing cavity and the exhaust cavity to communicate with the air outlet and the air inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com