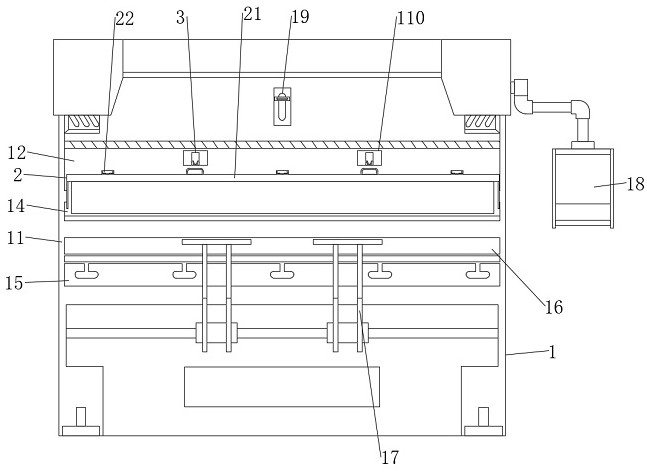

A single servo pump controlled electro-hydraulic bending machine

A technology of bending machine and servo pump, which is applied in the field of bending machines, can solve the problems of thin plates and quick clamping and hurt people, and achieve the effect of improving safety and stability, avoiding slack, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

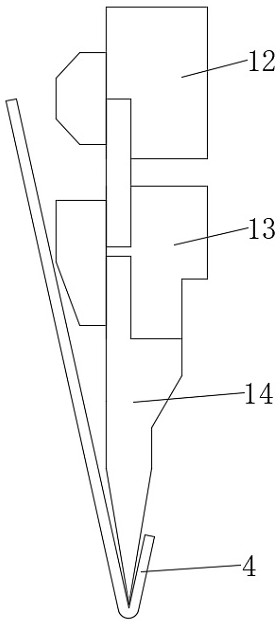

Embodiment Construction

[0041] Further, the connection between the card plate 36 and the connection block 35 is provided with a second return spring, and the width of the card plate 36 is less than

[0044] When the upper die 14 needs to be replaced, the pressing plate 28 can be pulled so that the front surface of the pressing plate 28 is in contact with the side wall of the movable groove 25, and then

[0045] It will be apparent to those skilled in the art that the invention is not limited to the details of the above-described exemplary embodiments, but also

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com