Method and device for measuring, predicting and optimizing milling tool marks on top surface of engine cylinder block

A technology of engine block and optimization method, which is applied in the direction of measuring/indicating equipment, milling machine equipment, milling machine equipment details, etc., to achieve the effect of strong theoretical persuasion and strong prediction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

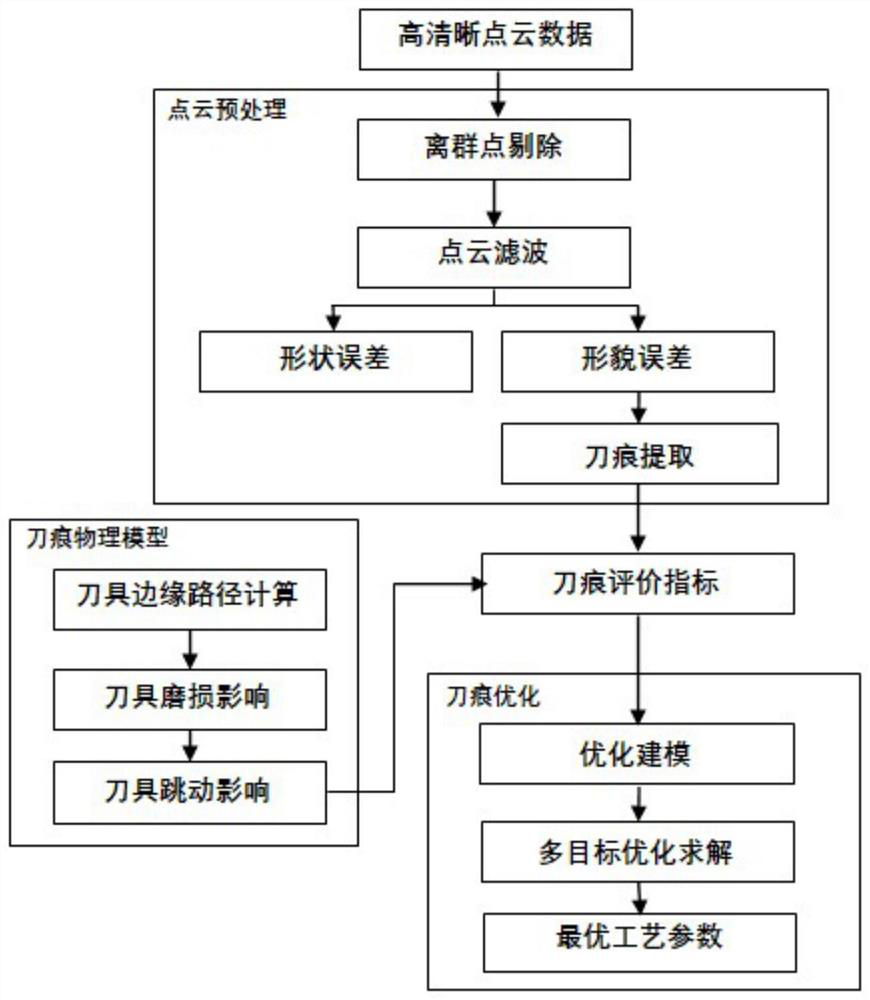

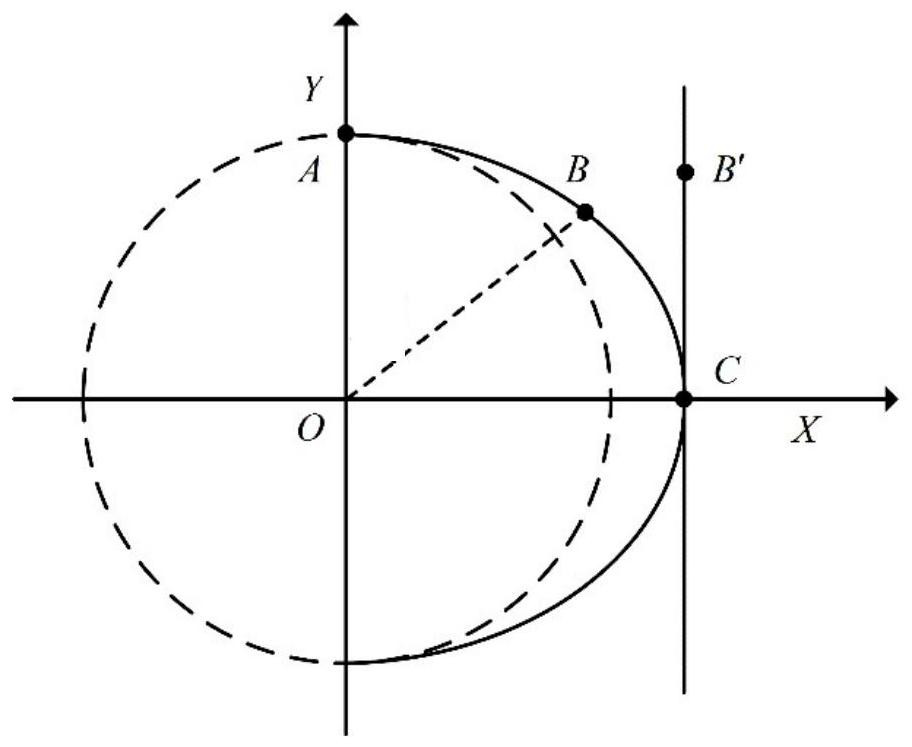

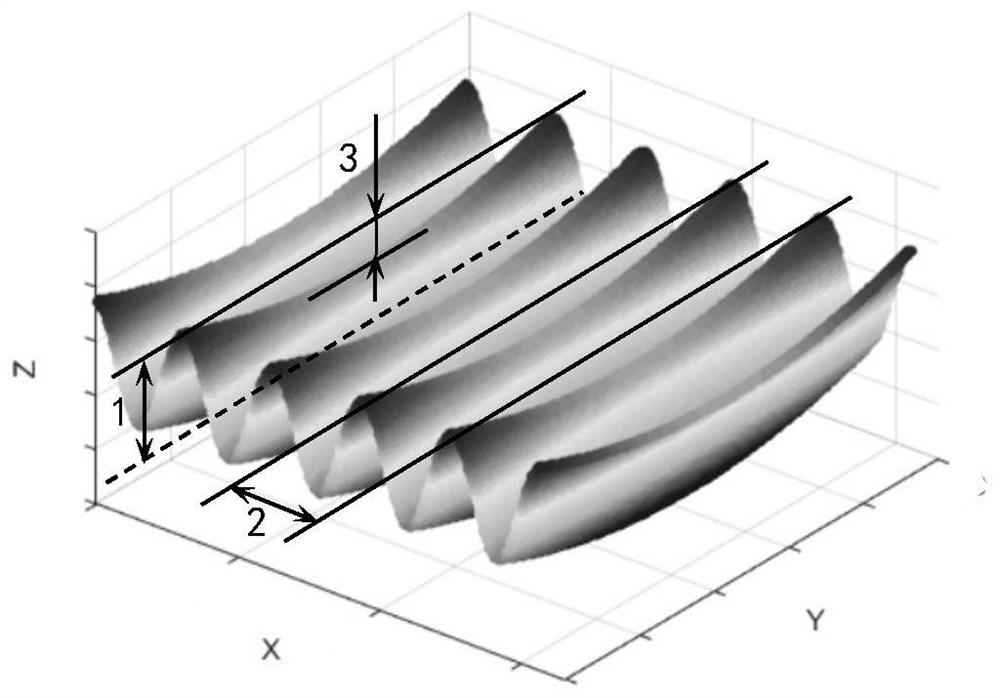

[0038] Such as Figure 1 to Figure 7 As shown, in this embodiment, the measurement prediction and optimization method based on the milling tool marks on the top surface of the engine block provided by the present invention includes the following steps:

[0039] Step 1: Preprocess the original 3D point cloud data of the top surface of the engine block obtained by high-definition measurement methods, including three operations of outlier elimination, filtering and knife mark conversion. For a known type of cylinder workpiece, the nominal height from the measurement plane to the reference plane is a known definite value, and the deviation between the measured actual height and the nominal height can also be obtained by subtracting the two. The critical threshold P is preset, and if the deviation value of any data point is greater than P, the data point will be regarded as an outlier and eliminated. After the outlier is eliminated, the point cloud data is filtered using the jigsa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com