Logistics Adaptive Shock Pads

A self-adaptive, shock-proof pad technology, used in containers, packaging, and bottle/can parts to prevent mechanical damage. , Improve the anti-stress effect

Active Publication Date: 2022-05-31

SHIJIAZHUANG VOCATIONAL TECH INST

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Traditional shockproof materials include plastic sponge, pearl cotton, polyamide, air bags, etc. Although these shockproof materials have good cushioning and shock absorption performance, their defects lie in their insufficient strength and weak compression resistance, especially in When transporting heavy goods, the strong pressure generated by the vibration of the heavy goods may exceed the compressive limit of the traditional anti-vibration pad, causing the anti-vibration pad to be crushed and unable to recover, and even more serious may even be crushed, so that it cannot effectively absorb shocks

[0004] Therefore, for heavy goods, anti-vibration pads not only need to have cushioning performance, but also need to have sufficient compression resistance to ensure that they can provide sufficient support for heavy goods to limit the vibration of heavy goods. Obviously, traditional anti-vibration pads cannot do this. To; In addition, the traditional anti-vibration pad thickness adjustment range is small, insufficient adaptability to the gap between the goods and the packing box

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

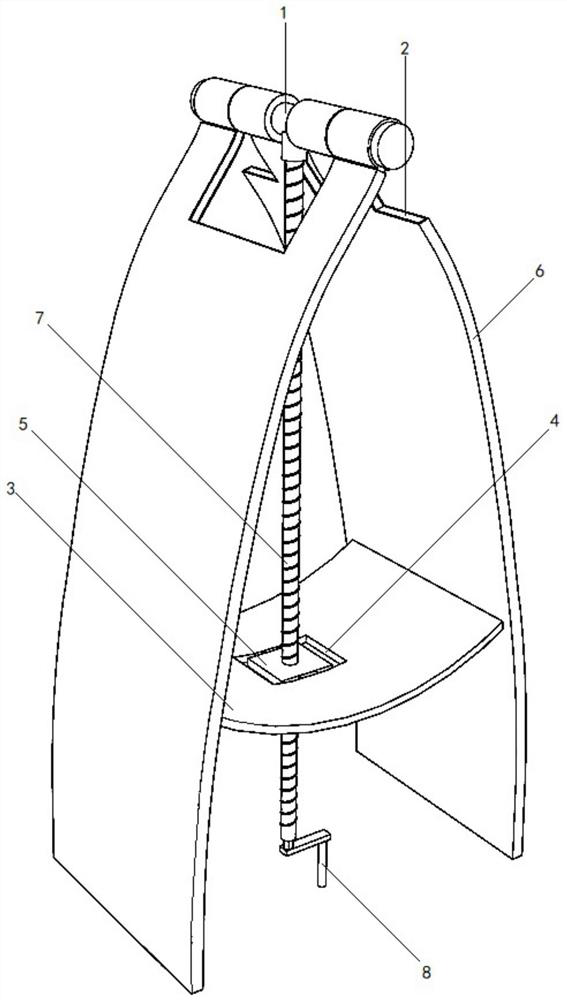

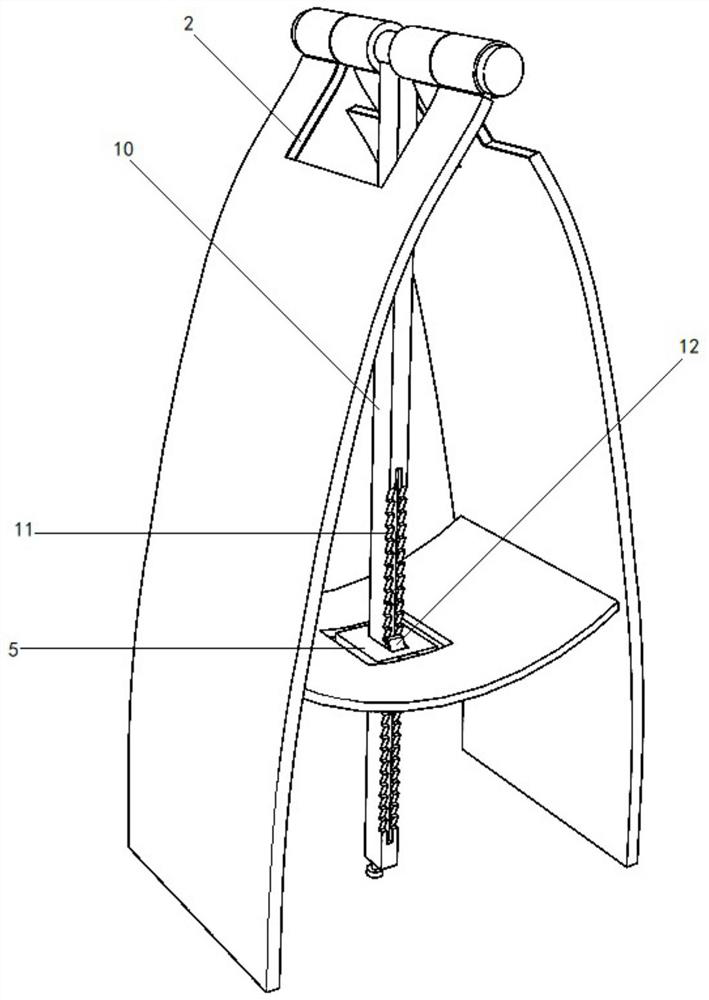

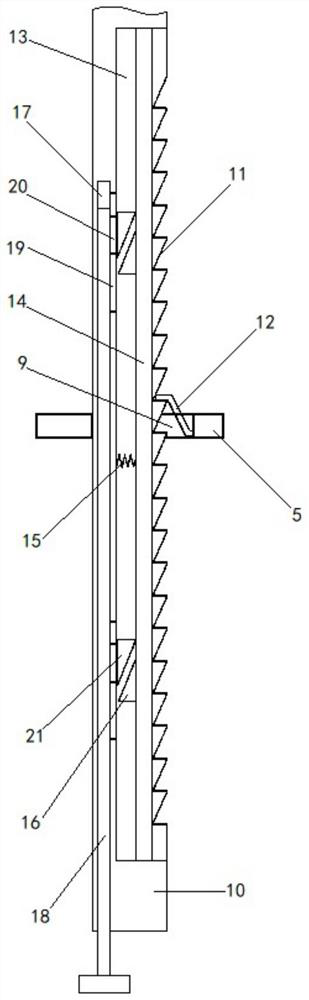

The invention discloses a logistics self-adaptive anti-vibration pad, which relates to the technical field of logistics anti-vibration. It includes a support shaft; the left and right sides of the support shaft are respectively provided with expansion plates; the upper ends of the expansion plates are respectively connected with the support shaft; The locking mechanism for the deformation range; the middle part of the support shrapnel is provided with an installation window; the middle part of the installation window is provided with a bearing block; A buffer sleeve is fixed to the corresponding socket on the support plate. The beneficial effect of the present invention is: the pressure resistance is strong, and it is convenient to adapt to the width of the gap between the goods and the packing box.

Description

Logistics adaptive shock pad technical field [0001] The present invention relates to the technical field of logistics shockproofing. Background technique In logistics transportation, the problem that the packing box does not match the size of the goods is very common. In order to prevent the goods from being transported Shake and collide everywhere on the way, resulting in damage to the goods, so the gap between the goods and the packaging box needs to be filled with shock-proof pads Charge. Traditional shock-proof materials have types such as plastic sponge, pearl cotton, poly dragon, air bag, etc. Although these shock-proof materials Both have good cushioning and shock absorption performance, but their shortcomings lie in their lack of strength and low compressive ability, especially in transportation. When transporting heavy goods, the strong pressure generated by the vibration of the heavy goods is likely to exceed the compressive limit of traditional shockproo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B65D25/02B65D81/05B65D25/10

CPCB65D25/02B65D81/05B65D25/101

Inventor 曲理萍杨晓洁杨利贤李怀

Owner SHIJIAZHUANG VOCATIONAL TECH INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com