Product suction filtration slot filtration discharge mechanism

A suction filter tank and filtration technology, which is applied in the field of product suction filter tank filter discharge mechanism, can solve the problems of affecting the filtering effect, reducing the filtering rate, and inconvenient cleaning, so as to ensure the service life, facilitate installation and use, and facilitate collection of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

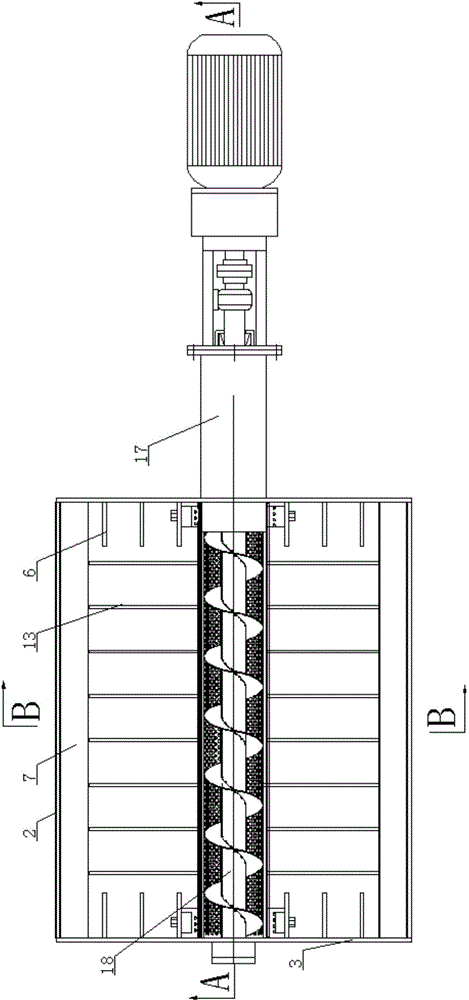

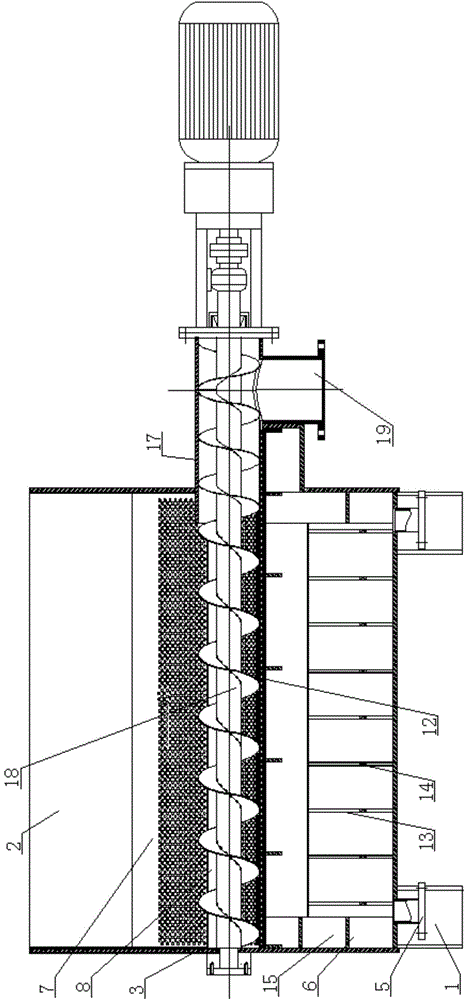

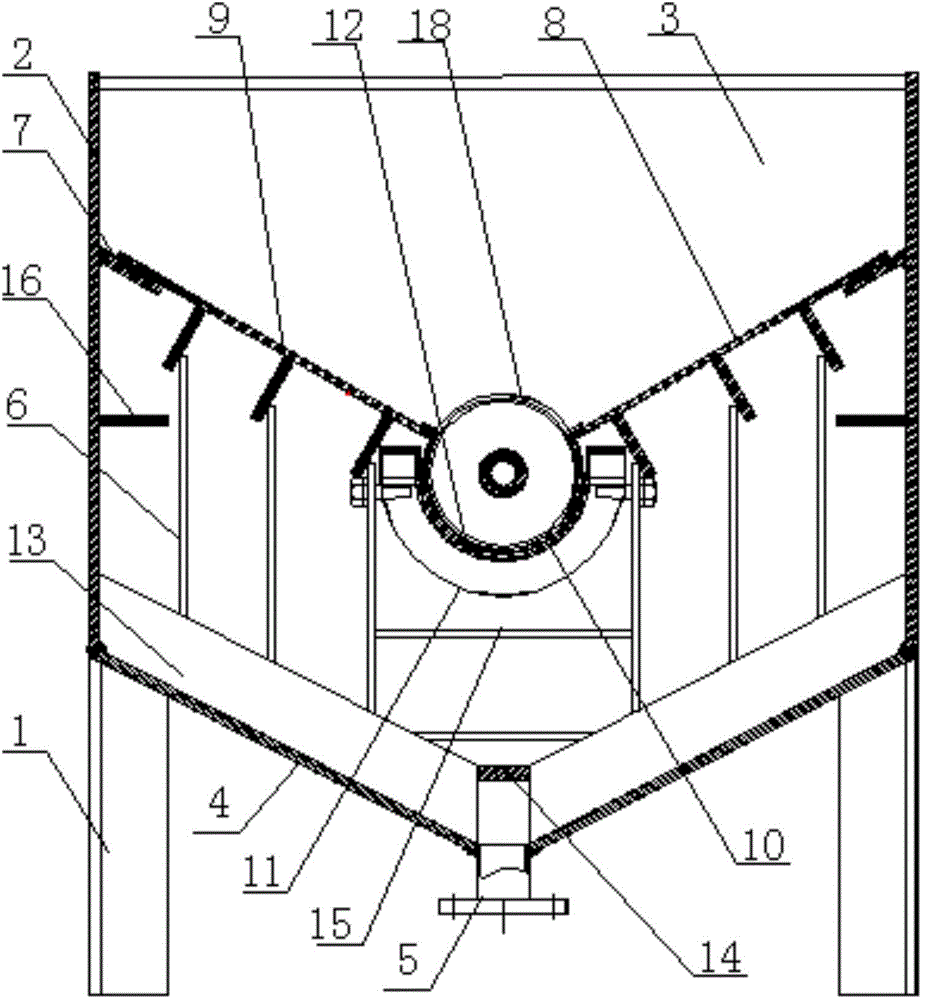

[0019] The specific implementation manner and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0020] like Figure 1-Figure 3 As shown, a filter discharge mechanism for a product suction filter tank includes a bracket 1, which supports a tank body surrounded by two side panels 2, two end panels 3 and a "V"-shaped bottom plate 4. The bottom of the tank body is provided with two first outlets 5, and a plurality of vertical end ribs 6 are symmetrically arranged on both sides of the inner wall of the end panel 3, and the lower end of the end ribs 6 Fixedly connected with the bottom plate 4, a filter screen support plate 7 is fixed on the side panel 2, a filter screen plate 8 is supported on the filter screen support plate 7, and the filter screen plate 8 is also supported by a bracket 9 On the end face vertical rib plate 6, an arc-shaped screen installation groove 10 is arranged between the two e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com