A uniform light rod fixing device

A technology of fixing device and light dodging rod, which is applied in the field of direct writing exposure machine, can solve the problems that the screw installation torque is not easy to control, affect the dodging effect, and the dodging effect is invalid, so as to achieve good installation effect and improve the uniformity of light , to ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1 Homogenizing rod fixing device

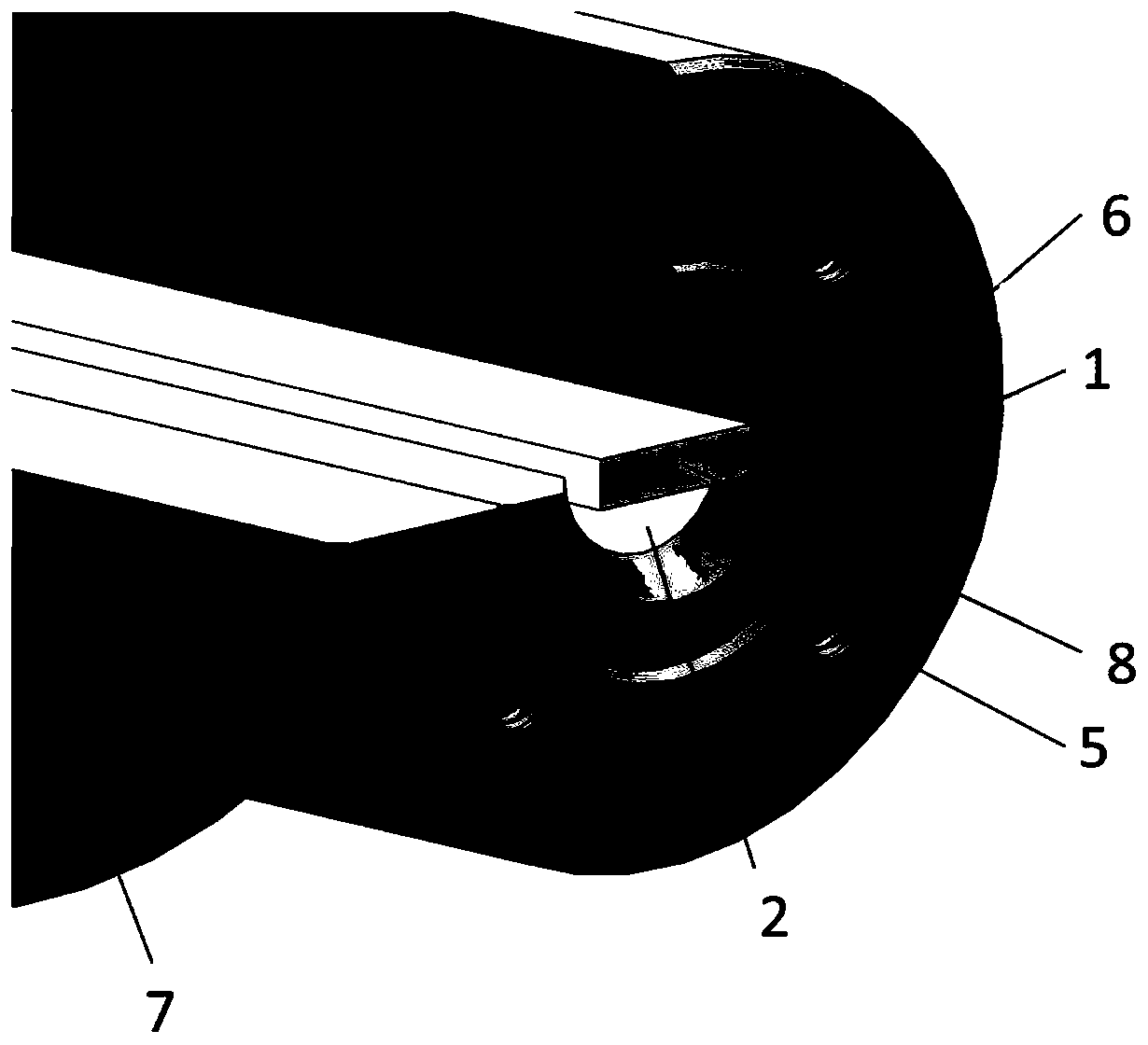

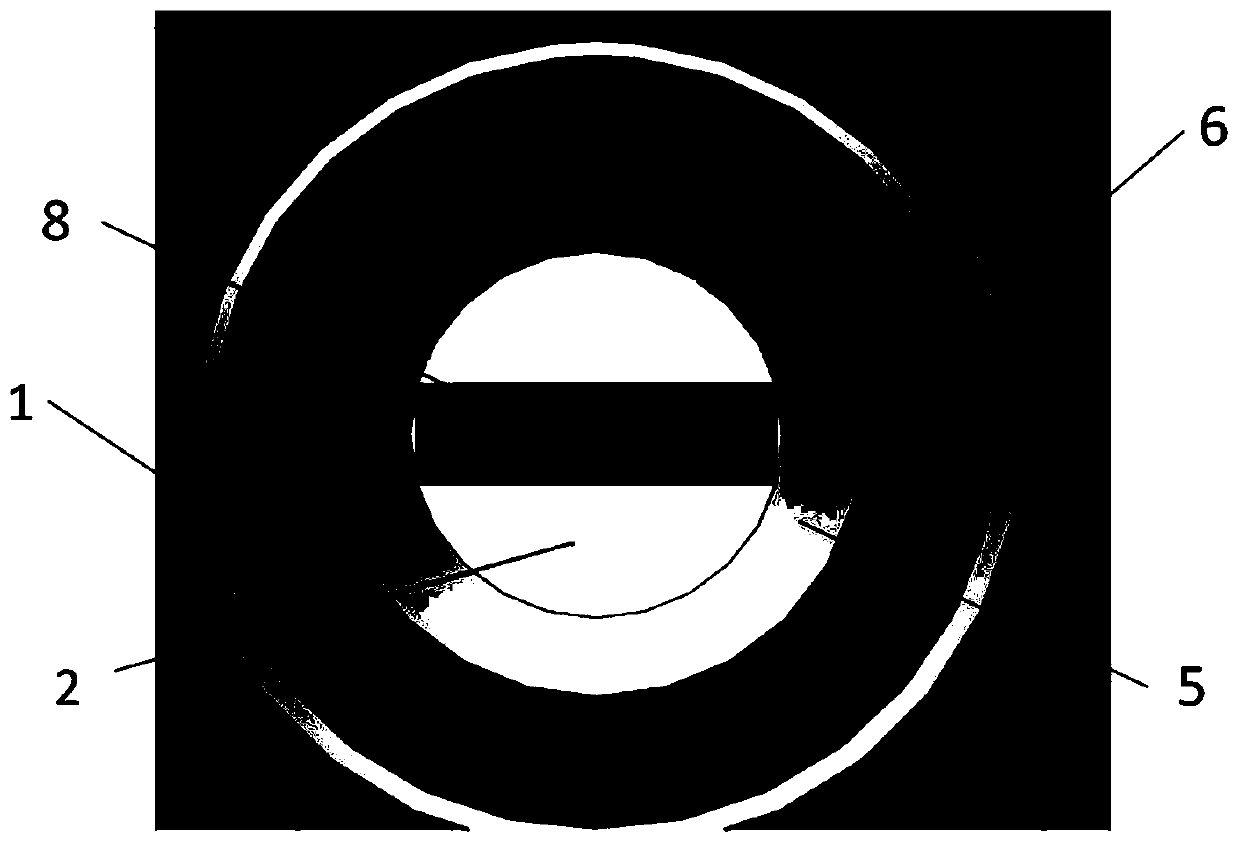

[0040] Such as figure 1 , figure 2 Shown is the description of the homogenizing rod fixing device of the invention.

[0041] The invention provides a homogenizing rod fixing device, such as figure 1 , figure 2 As shown, it includes a soft support 1 provided with a through hole 2. The through hole 2 is cylindrical as a whole, and the hole diameter is consistent from beginning to end, that is, the through hole is a contact support hole 3 as a whole. The shape is a cylinder, coaxial with the through hole 2. The cross-sectional diameter of the soft support 1 is 13mm, and the material of the soft support 1 is PTFE with a Shore hardness of 55-65. The length of the through hole 2 is equal to uniform The length of the light rod 8 has an aperture of 4.65 mm, the diameter of the circumscribed circle of the cross section of the fixed homogenizing rod 8 is 4.68 mm, the two ends of the through hole are provided with an orifice chamfer 5, an...

Embodiment 2

[0049] Embodiment 2 Homogenizing rod fixing device

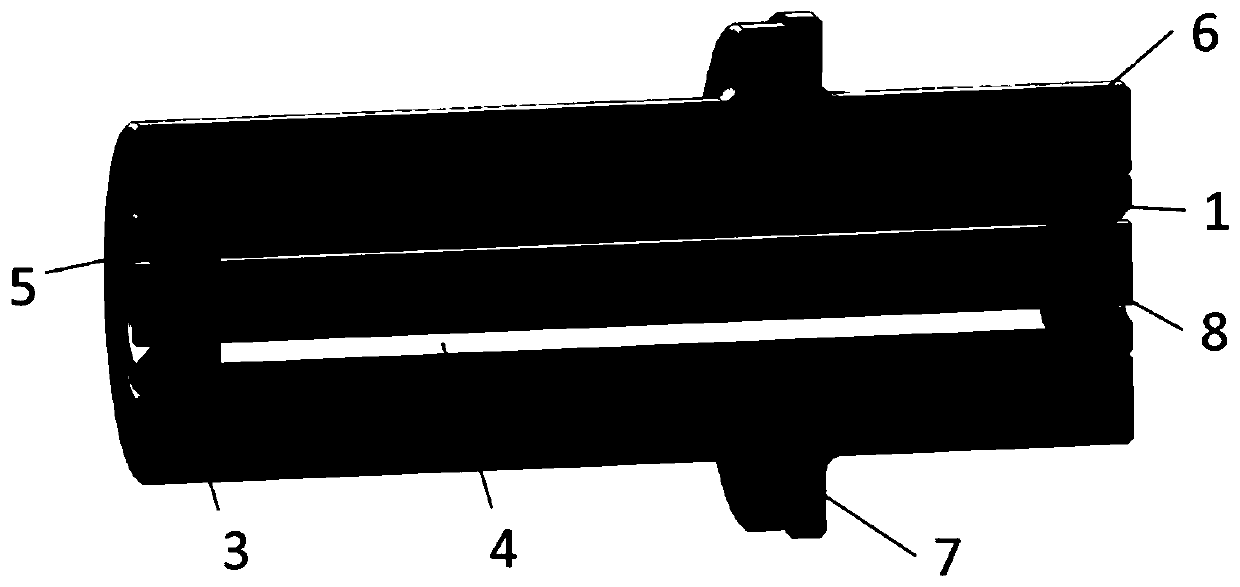

[0050] The invention provides a homogenizing rod fixing device, such as Figure 1-Figure 3 As shown, it includes a soft support 1 provided with a through hole 2, a contact support hole 3 is provided at both ends of the through hole 2, a cylindrical non-contact hole 4 in the middle part of the through hole 2, a non-contact hole 4 Coaxial with the contact support hole 3; the shape of the soft support 1 is a cylinder, coaxial with the contact support hole 3. The cross-sectional diameter of the soft support 1 is 13mm, and the material of the soft support 1 is Shore hardness 55 -65 PTFE, the length of the through hole 2 is equal to the length of the homogenizing rod 8, the diameter of the contact support hole 3 is 4.65mm, the diameter of the circumscribed circle of the cross section of the fixed homogenizing rod 8 is 4.68mm, non-contact The hole 4 has a hole diameter of 5 mm, and one end of the contact support hole 3 is provided wi...

Embodiment 3

[0053] Embodiment 3 Homogenizing rod fixing device

[0054] The invention provides a homogenizing rod fixing device, such as figure 1 , figure 2 with Figure 4 As shown, it includes a soft support body 1 provided with a through hole 2. One end of the through hole 2 is provided with a contact support hole 3, the other end is a cylindrical non-contact hole 4, the non-contact hole 4 and the contact support hole 3 Coaxial: The shape of the soft support 1 is a cylinder, coaxial with the contact support hole 3. The cross-sectional diameter of the soft support 1 is 13mm, and the material of the soft support 1 is Poly Si with a Shore hardness of 55-65 Vinyl fluoride, the length of the through hole 2 is equal to the length of the homogenization rod 8, the contact support hole 3 has a diameter of 4.65mm, the fixed diameter of the homogenization rod 8 has a cross-sectional circumscribed circle diameter of 4.68mm, and the non-contact hole 4 has a diameter of 5mm , One end of the contact sup...

PUM

| Property | Measurement | Unit |

|---|---|---|

| verticality | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com