Self-adaptive anti-vibration pad for logistics

An adaptive, anti-vibration pad technology, applied in the direction of preventing mechanical damage, rigid containers, bottle/can parts, etc., can solve the problems of weak compression resistance, insufficient strength, and inability to effectively absorb shocks, etc., to achieve improved The effect of anti-compression and stable placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

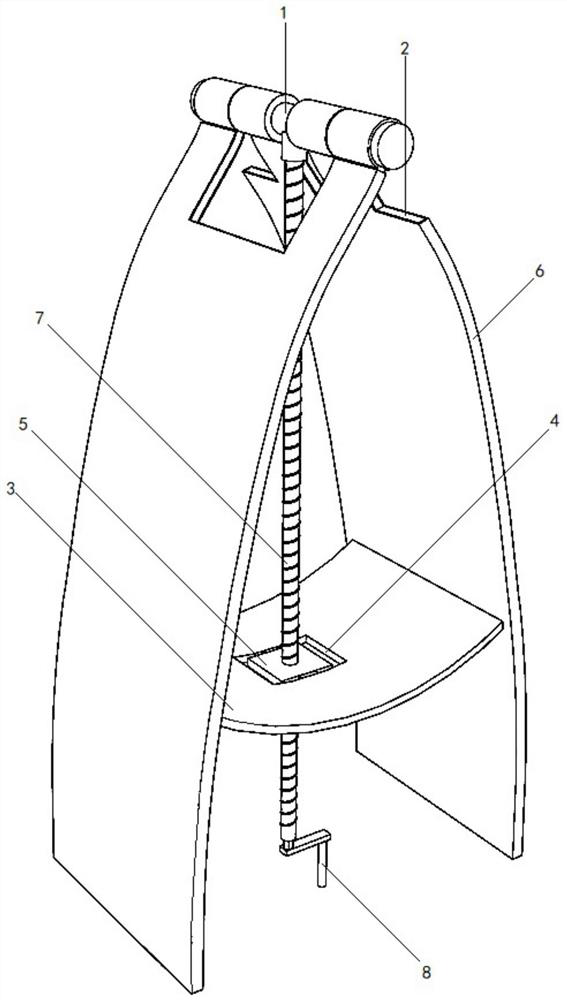

Embodiment 1

[0030] In this embodiment, the locking mechanism is a threaded locking mechanism. When adjusting the opening range of the two expansion boards 2, it is only necessary to rotate the rocker 8 to drive the screw 7 to rotate, and the screw 7 can be threadedly connected to the bearing block 5. , change the degree of deformation of the supporting elastic piece 3, and then change the opening range of the two expansion plates 2, and stop the rotation of the screw rod 7, and the opening range of the two expansion plates 2 will be locked.

Embodiment 2

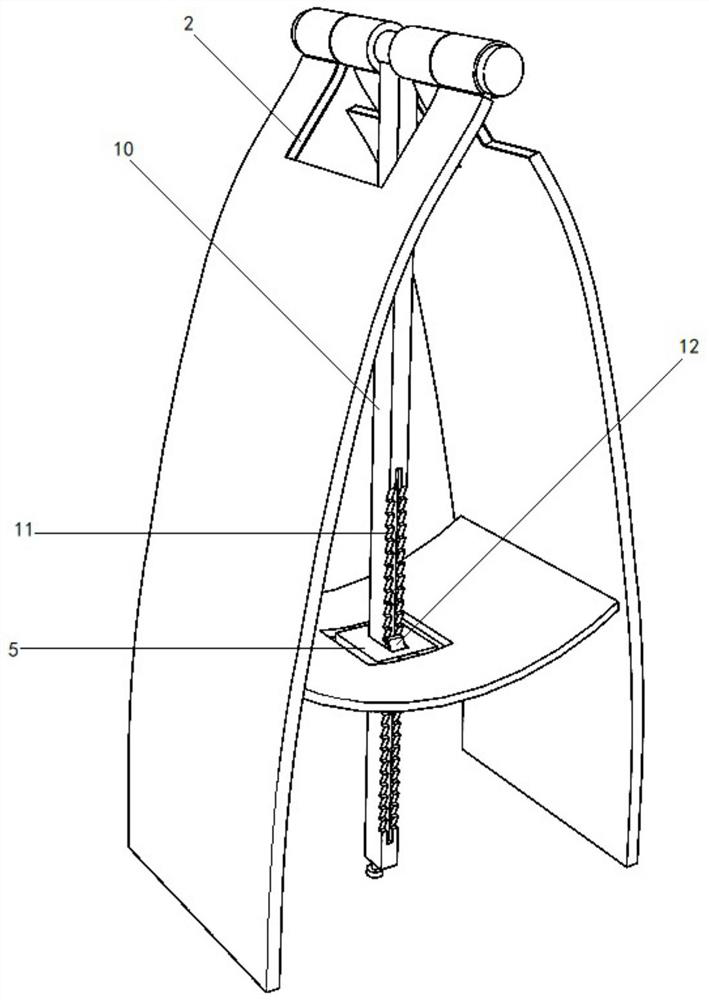

[0032] The difference between this embodiment and Embodiment 1 is that the locking mechanism adopts a snap-in locking mechanism and an unlocking mechanism is provided. In this embodiment, when adjusting the opening range of the two expansion boards 2, first use the unlocking mechanism to release the buckled state of the limit spring piece 12 and the card slot 11, and then the opening range of the two expansion boards 2 can be adjusted freely , and then use an external tool such as a vise to adjust the opening range of the two expansion plates 2 in place, and then release the effect of the unlocking mechanism, so that the limit shrapnel 12 is buckled with the corresponding card slot 11, and the two expansion plates The opening range of 2 is locked.

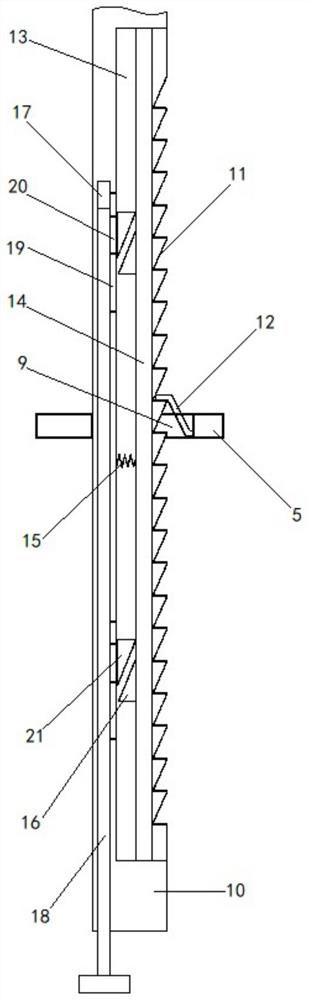

[0033] The unlocking mechanism in the initial state is as image 3 As shown, the extension spring 15 is in an unstretched state at this time, and the push bar 14 has not reached the draw-in slot 11; Slide in 18, make wedge-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com