A long pre-embedded component with controllable flatness and method

A flatness, pre-embedded technology, applied in the processing of building materials, construction, building structure, etc., can solve the problems of high flexibility of steel plates, easy bending of steel plates, uneven quality, etc., to achieve reasonable design, high stability, and structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

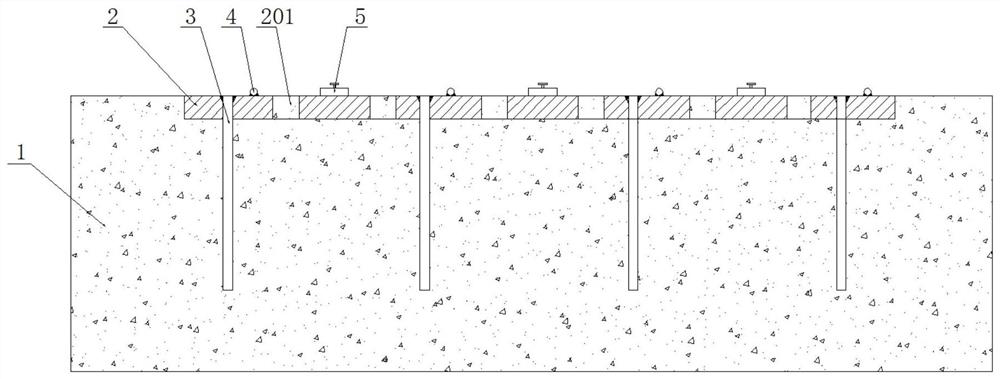

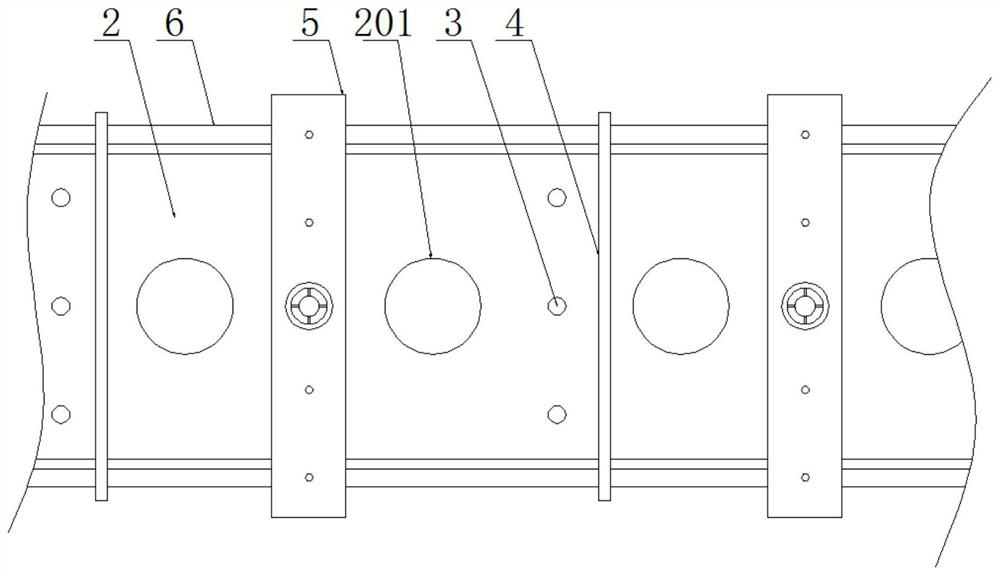

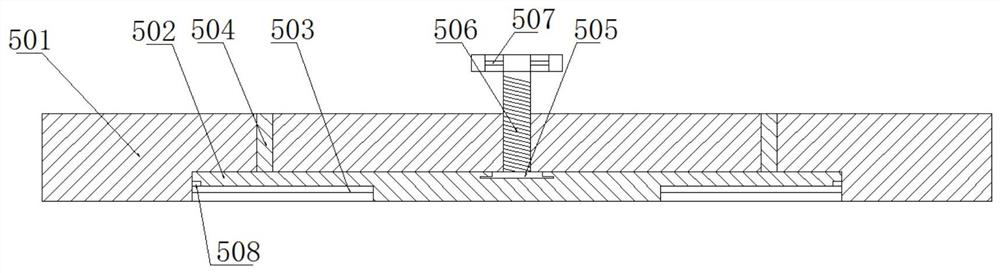

[0029] like Figure 1-4 As shown, a long pre-embedded component with controllable flatness is provided. The long pre-embedded component is arranged between the formwork and is located near the upper end of the formwork. Steel plate 2, several pouring reserved holes 201 set on the pre-embedded long steel plate 2, several pre-embedded steel plate anchor bars 3 welded on the pre-embedded long steel plate 2, several steel plates connected to the upper end of the pre-embedded long steel plate 2 Hanging frame bars 4 and several pressure-applying mechanisms 5, several pre-embedded steel plate anchor bars 3 are evenly welded on the pre-embedded long steel plate 2, and several pouring reserved holes 201 are evenly distributed on the pre-embedded long steel plate 2 to apply pressure. The mechanism 5 is set above the embedded long steel plate 2; the steel plate hanger rib 4 can resist the downward bending of the embedded long steel plate 2. Because the embedded part is long and has a cer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com