Free gravity tempering support for artillery long pipe parts

A technology for long tubes and parts, which is applied in the field of free gravity tempering supports for long tube parts of artillery. It can solve the problems of inability to quantify and the influence of workpiece deformation, and achieve the effects of convenient operation, improved workpiece quality, good practicability and economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

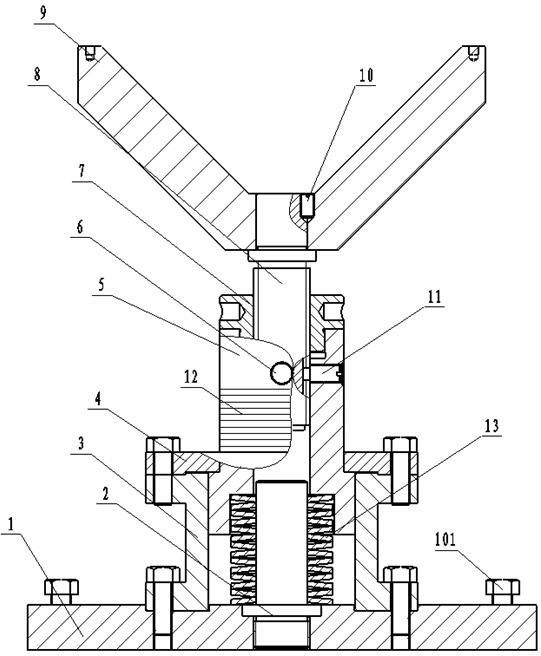

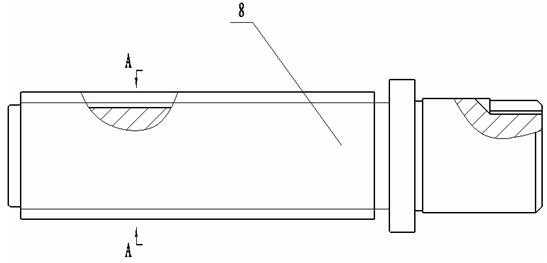

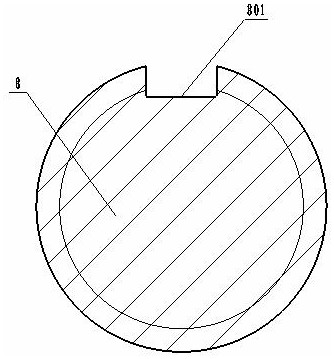

[0017] like figure 1 As shown in -4, a free gravity tempering bracket for artillery long tube parts, including a base 1, a guide rod 2, a guide sleeve 3, a cover plate 4, a floating sleeve 5, a V-shaped iron 9 and a butterfly spring 13, the base 1 A guide rod 2 in a vertical direction is threadedly connected to the center of the upper plane. The outer part of the guide rod 2 is fitted with a butterfly spring 13; The spring 13 is pressed against the upper plane of the top of the butterfly spring 13. The I-shaped guide sleeve 3 with a clearance fit passes through the outer ring under the floating sleeve 5, and the outer ring at the bottom of the guide sleeve 3 is connected to the base 1 through bolts. Fixed connection; the annular cover plate 4 passes through the cylinder of the floating sleeve 5 with clearance fit, and is located above the bottom outer ring of the floating sleeve 5 and the top outer ring of the guide sleeve 3, and the cover plate 4 is connected to the guide sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com