A kind of fire pipe fitting and its installation method

An installation method and technology for pipe fittings, applied in the direction of pipes/pipe joints/pipe fittings, flange connections, passing components, etc., can solve the problems of high work intensity of installers, achieve the effect of improving connection stability and reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

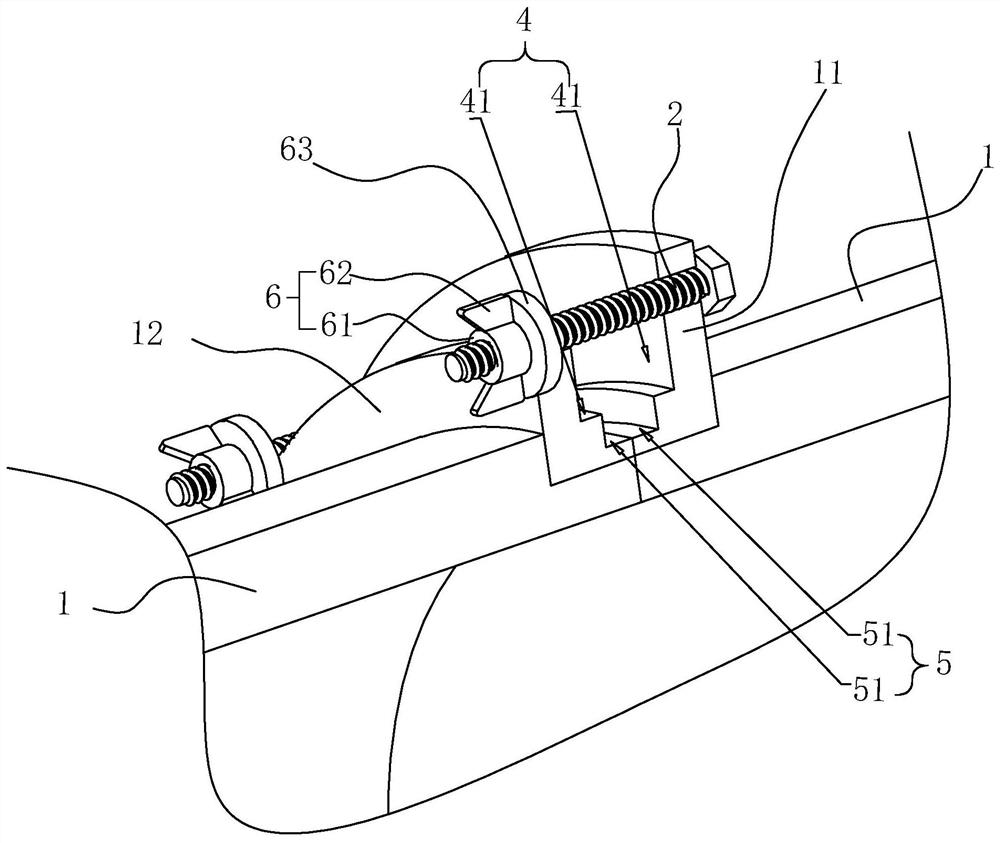

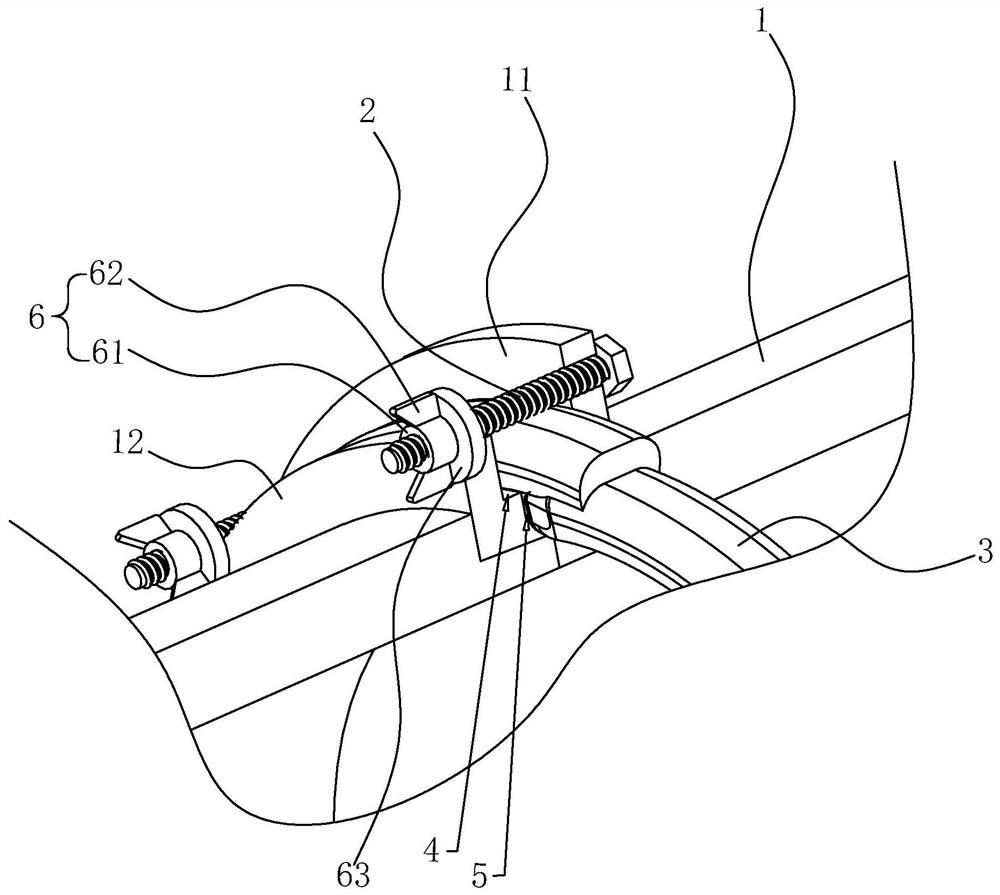

[0034] The following is attached Figure 1-4 The application is described in further detail.

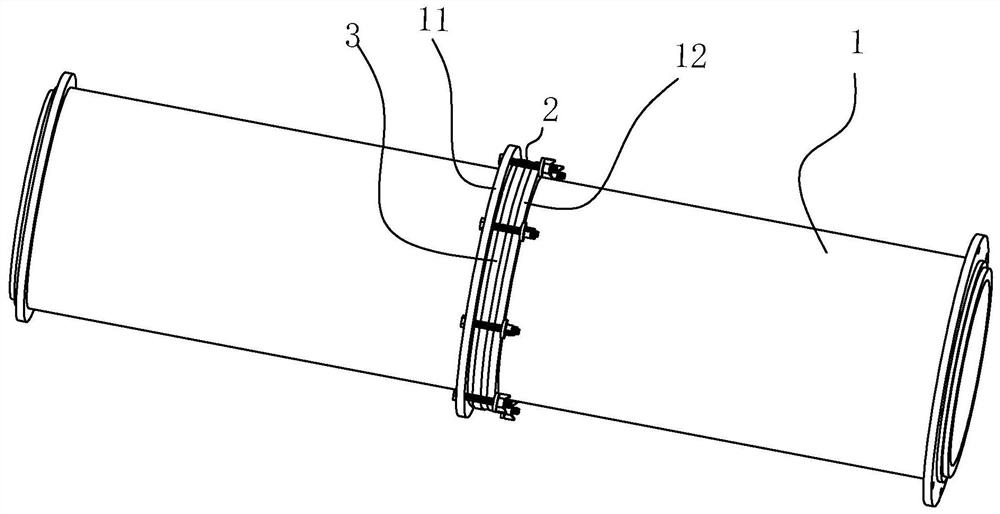

[0035] The embodiment of the application discloses a fire-fighting pipe fitting and an installation method thereof. refer to figure 1 and figure 2 A fire-fighting pipe fitting includes a plurality of pipeline monomers 1 spliced in sequence, one end of the pipeline monomer 1 is fixedly sleeved with a first annular protrusion 11, and the outer circumference of the other end is fixedly sleeved with a second annular protrusion 12, The first annular protrusion 11 penetrates a plurality of prefabricated holes in a direction parallel to the axis of the pipeline unit 1 , and the plurality of prefabricated holes are circumferentially distributed on the outer peripheral surface of the pipeline unit 1 . The first annular protrusion 11 is provided with a plurality of screw rods 2, and the plurality of screw rods 2 pass through a plurality of prefabricated holes one by one. The outer diame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com